Responsible Supply Chain

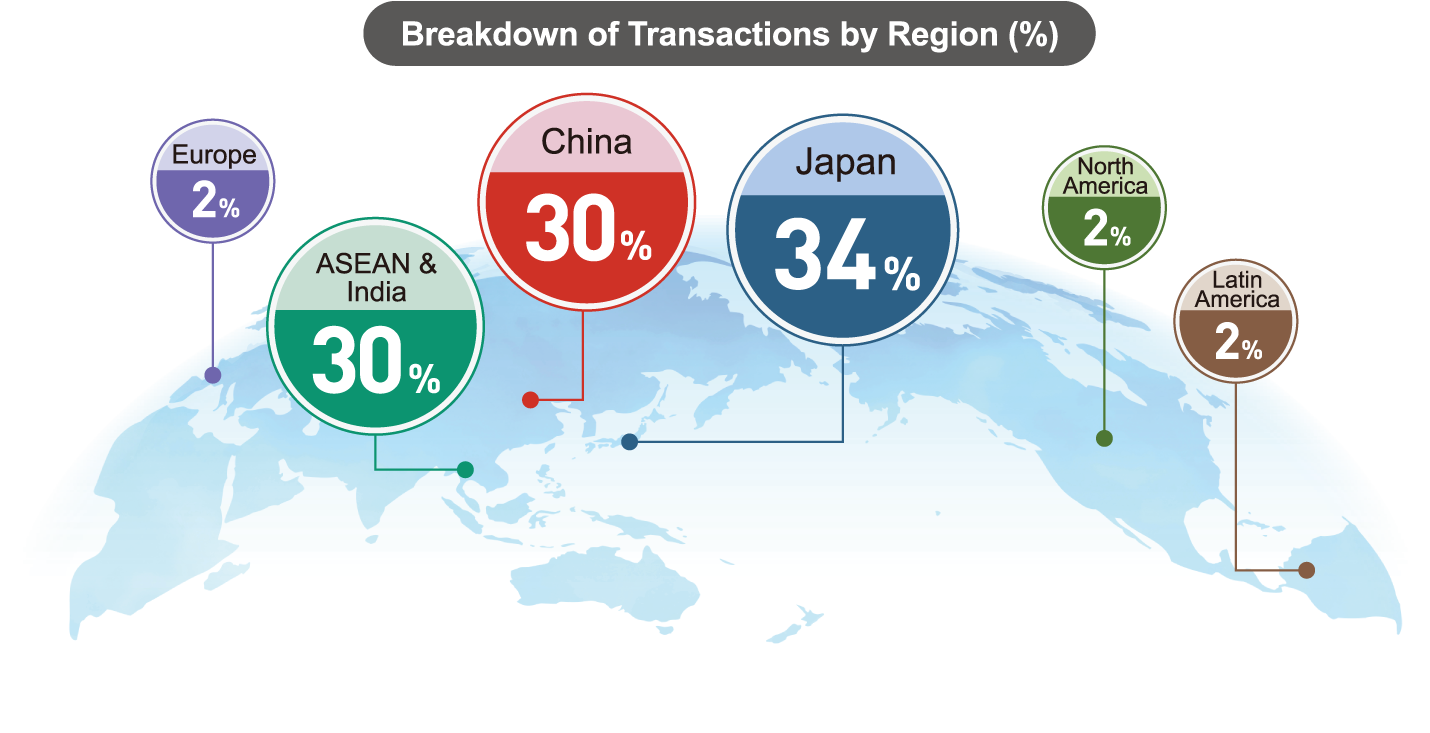

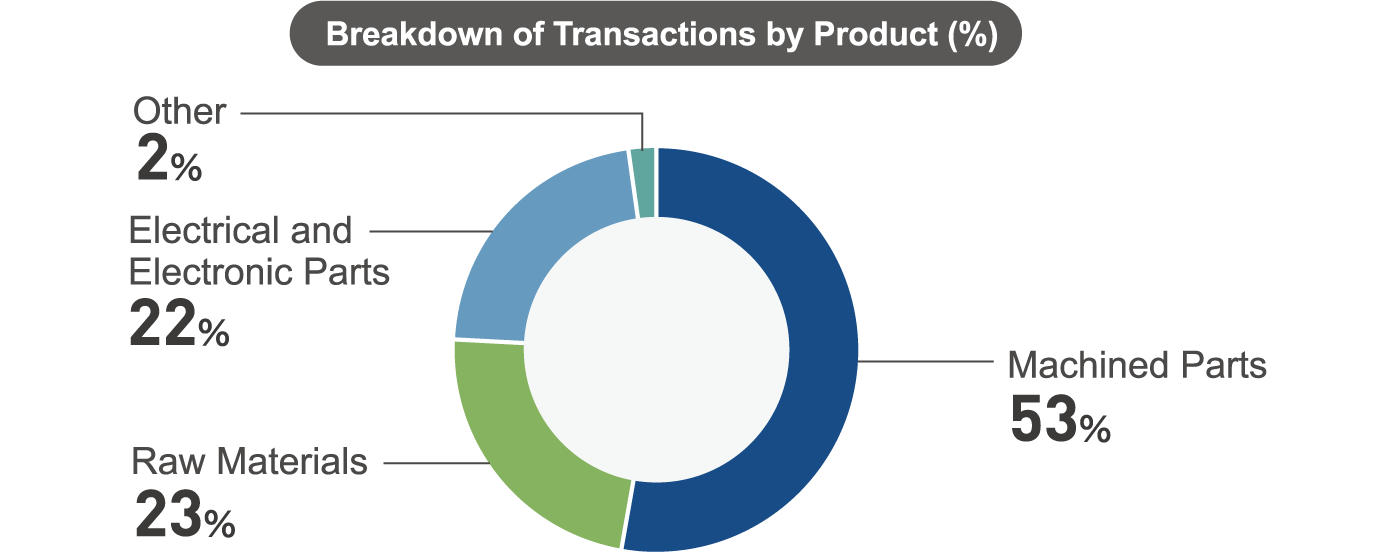

Panasonic Group does business with approximately 13,000 suppliers worldwide. Panasonic Group strives to do business with suppliers that not only provide superior technology and quality but also fulfill their social responsibilities including human rights and environmental considerations, healthy workplace environment, and fair transactions. The parts and materials we purchase range from raw materials to electrical/electronic components and processed parts. Our suppliers are located in various regions and countries, meaning that some parts and materials come from regions and countries with many migrant workers. By region, the percentage of suppliers providing parts and materials used directly in manufacturing was 34% from Japan, 30% from China, 30% from ASEAN/India, 2% from Europe, 2% from North America, and 2% from Latin America. By industry, 53% were in machined parts, 23% in raw materials, 22% in electrical and electronic parts, and 2% in others (including molds) (As of March 31, 2025; excludes transactions by Panasonic Automotive Systems Co., Ltd.).

Policy

▪Procurement Policy

Panasonic Group has summarized its core thinking on procurement in the following 3-item set of Procurement Policy. The fundamental basis of this policy is the concept that, “based on relationships of mutual trust, and through diligent study and cooperation, our suppliers are invaluable partners in creating the value our customers demand”.

- Implementation of Global Procurement Activities

The Company globally establishes partnerships with suppliers to respond to production activities on a global scale, and works to create the functions and values our customers demand based on relationships of mutual trust and through diligent studies and cooperation. - Implementation of CSR Procurement

Complying with laws and regulations, social norms, and corporate ethics, the Company promotes procurement activities, together with suppliers, that fulfill their social responsibilities, such as human rights, labour, safety and health, global environmental conservation, and information security. - Procurement Activities Working Closely with Suppliers

In order to achieve product values expected by customers, the Company serves as the contact point of suppliers with respect to information, such as the market trends of materials and goods, new technologies, new materials, and new processes, and works to ensure and maintain the quality of purchased goods, realize competitive prices, and respond to market changes.

In April 2022, we established the “Rules on Supply Chain Compliance” to strengthen our efforts to promote CSR in the supply chain, with our basic policy on supply chain compliance and corporate rules for its implementation. We have also issued the Panasonic Supply Chain CSR Promotion Guidelines (“CSR Guidelines”) for our suppliers to promote collaboration in responsible procurement efforts.

▪Clean Procurement

Because Panasonic Group believes that “a company is a public entity of society”, we engage in fair and equitable transactions with our global suppliers. With a need for a more stringent sense of moderation and ethics and to maintain healthy relationships with suppliers, in 2004, we released our Clean Procurement Declaration and have followed this declaration in our procurement activities since. In Japan, we promote understanding and awareness of “clean procurement” among our procurement staff by providing annual e-Learning and training materials.

Prohibition of Receiving Money and Valuables from Suppliers and Prohibition of Accepting Any Form of Hospitality, Entertainment or Meals

The Group established “Rules on Gift and Hospitality for AntiBribery / Anti-Corruption” in its internal regulations, applied at the global level. These strict rules apply to the acceptance of gifts, meals, entertainment and travel invitations from our business partners, including suppliers. They stipulate general rules regarding the rationality and balance in light of the purpose, value and frequency of gifts, meals, entertainment and travel invitations, and local customs, and the absence of improper influence on business judgement. More detailed standards and stricter rules are also set for each region.

Responsible Executive and Framework

The Panasonic Holdings Corporation (“PHD”) representative director and executive vice president serves as the officer in charge of procurement (as of August 2025). Panasonic Group established a Groupwide framework to foster cooperation in promoting responsible procurement among all Group operating companies and regional procurement divisions. Each of our operating companies, their business divisions, or other relevant Group companies are responsible for applying the PDCA cycle to their practice of responsible procurement, following the Group’s internal rules, standards, and manuals. The Global Procurement Division of Panasonic Operational Excellence Co., Ltd. (“PEX”) fills the role of providing Groupwide measures and support to all operating companies. The heads of procurement at the operating companies and business divisions discuss any related issues at regular Groupwide meetings and take appropriate solutions.

Supply Chain Due Diligence

▪Enforcement of the Panasonic Supply Chain CSR Promotion Guidelines

We, the Panasonic Group, adhere to international norms and principles, such as the United Nations “Guiding Principles on Business and Human Rights”, and require suppliers to affirm them. To show our approach to CSR procurement and clearly convey the requirements to suppliers, we have established the CSR Guidelines, and we share them at the start of transactions. The contract obligates suppliers to comply with the guidelines. The CSR Guidelines stipulate the following provisions, while taking into account laws, regulations, and principles of international norms:

- Labor rights: Prohibition of forced labor or child labor, appropriate working hours, decent wages, humane treatment, elimination of discrimination, freedom of association

- Occupational health and safety: Training to ensure workplace safety and emergency preparedness, safety measures for machinery and equipment, and occupational health and safety rules for facilities

- Environment: Compliance with the “Panasonic Group’s Green Procurement Standards”

- Ethics: Prohibition of corruption and bribery, and promotion of fair business and responsible minerals procurement

- Information security: Prevention of information leaks and protection against computer and network threats

- Product quality and safety: Creation of a product quality management system, provision of accurate product and service data, and maintenance of product safety

- Contributions to society: Contributions to society and local communities

- Management systems

The CSR Guidelines are prepared in Japanese, English, and Chinese and we both keep them on our website and endeavor to distribute to our suppliers and notify them of any revisions. We also ensure that we share these guidelines with our suppliers at workshops as necessary. We ask our suppliers to communicate the requirements of the guidelines to their suppliers and subsequent suppliers, and to check their compliance status. For further details, please visit the following website.

▪Obtaining Commitment from the Suppliers

We, the Panasonic Group, require that suppliers affirm the Panasonic Group’s Code of Ethics & Compliance and the Panasonic Group’s Human Rights and Labor Policy, and at the start of transactions for materials and components for the manufacturing of Panasonic products, we make it mandatory to conclude a Master Global Purchasing Agreement that stipulates compliance with the CSR Guidelines. In addition, we stipulate in the CSR Guidelines a respect for human rights as expressed in United Nations norms and principles, an evaluation of the status of suppliers’ human rights initiatives and the implementation of prevention / mitigation / corrective measures, a request for compliance with tier 2 suppliers, and a request for cooperation with the Panasonic Group’s human rights due diligence. Since establishing the CSR Guidelines in 2016, we have distributed them to suppliers for awareness and dissemination and have initiated the CSR Self-Assessments described below. In the revised template of the Group’s Master Global Purchasing Agreement, effective as of April 2022, we have mandated that our suppliers comply with these CSR Guidelines. We also aim to ensure that all suppliers make commitments without exception, so we began asking existing suppliers to submit compliance agreements after revising the CSR Guidelines in December 2022. As of now, over 90% of our suppliers have submitted their agreements.

▪Conducting CSR Self-Assessments and Audit

To promote human rights due diligence and other aspects of CSR throughout the supply chain, the Group requires its suppliers to conduct CSR Self-Assessments.

The CSR Self-Assessments are structured based on the CSR Guidelines, and we require that all new suppliers conduct the assessments before we start transactions with them. We also require our existing suppliers to conduct them regularly.

We conduct CSR Self-Assessments using a web-based questionnaire, which reduces the burden on suppliers and the Group, and improves collection efficiency and response accuracy. As of March 31, 2025, we have collected responses from more than 12,300 suppliers, representing 98% of the intended respondents. After identifying issues, particularly those identified as priority management items in the CSR Self-Assessments, such as labor conditions for migrant workers, we will visit suppliers, check on-site conditions, hold interviews, and investigate issues and work to correct them. We will continue to collect these assessments from our suppliers on a regular basis.

Since April 2022, the Group has begun work on initiatives to build a structure for human rights due diligence. While incorporating guidance from outside experts, the Group has compiled a table to assess human rights risks at our suppliers by using risk indicators and indices provided by international organizations in order to identify suppliers for which action should be taken on a priority basis.

Each operating company narrowed down the audit targets from among these identified suppliers based on the aforementioned risk approach and conducted supplier audits using the supplier audit plans they formulated. Since fiscal 2024, they have conducted audits for a total of 271 suppliers (22 of which were audited by third-party organizations). In fiscal 2026, we aim to complete audits of suppliers that require the highest priority.

The items identified through audits are shown in the table below. We have asked suppliers to improve these items, and we are monitoring their progress.

Area | Items requiring improvement |

|---|---|

| Management systems |

|

| Labor |

|

| Health and safety |

|

| Environment |

|

| Ethics |

|

| Information security |

|

▪Industry Collaboration Initiatives

The Group is a member of the Responsible Business Alliance (RBA) and promotes responsible business conduct. We also participate in the Sustainable Procurement Partnership Initiative Task Force under the Responsible Supply Chain Working Group of the Japan Electronics and Information Technology Industries Association (JEITA) CSR Committee, promoting human rights due diligence throughout the industry’s supply chain, including our suppliers. We also pursue industry collaboration to enhance awareness of and improve investigation efficiency in minerals procurement through our participation in JEITA’s Responsible Minerals Trade Working Group. Specifically, we are collaborating with domestic and international industry associations to promote proper initiatives for responsible mineral procurement through seminars, investigative briefings, and thorough reviews of smelting and refining plant information. Moreover, the Group has been involved in the Responsible Minerals Initiative (RMI) since 2017 to learn about the latest industry trends and promote best practices in procurement.

Initiatives for a Harmonious Relationship with the Environment

We strive to reduce the negative impact on the environment through cooperation with our suppliers and logistics partners. For details, please refer to the “Collaboration Across the Supply Chain” section in the “Environment” chapter.

Responsible Minerals Procurement

▪Our Basic Stance

Panasonic Group recognizes that the procurement of certain minerals (notably tin, tantalum, tungsten, gold, cobalt, and mica) carries a risk of funding organizations in conflict-affected areas and risks related to human rights abuses, child labour at mining sites, harsh working conditions, environmental destruction, and corruption in high-risk areas. This is a matter of grave social concern, and to fulfill our corporate social responsibility, Panasonic Group is engaged in the responsible procurement of minerals in its global supply chain.

Of course, there are companies and individuals in those same areas who conduct their business legally at the same time. Therefore, while we remain mindful of our obligation to avoid using minerals associated with illegal or unethical practices, we strive to ensure that this does not hinder the business activities and livelihoods of legitimate companies and individuals. To this end, it is necessary for us to work in partnership with a wide range of stakeholders including national governments, companies, and NPOs that are working toward creating sound minerals supply chains in the target areas.

We will keep conducting its activities based on the “Due Diligence Guidance” of the OECD (Organization for Economic Co-operation and Development) and build management processes in line with global standards.

The promotion of responsible minerals procurement requires conducting due diligence throughout the entire supply chain, from upstream mining companies to smelters, refineries, and downstream enterprises. We require that all related suppliers provide information on smelters / refineries throughout the supply chain, and we aim to procure from suppliers who don’t present any issues. We also participate in the RMI to promote industrywide efforts.

▪Responsible Minerals Survey Initiatives

Responsible minerals survey requires cooperation from all our suppliers going back to the refineries and smelters. Panasonic Group uses industry-standard survey forms issued by RMI to conduct surveys, including the tin-tantalum-tungsten-gold (3TG) survey form (CMRT) and the cobalt-mica survey form (EMRT).

The Panasonic Group conducts surveys regarding responsible minerals on the suppliers of each operating company and business site. In fiscal 2025, we collected responses from 1,470 of 1,508 suppliers that we asked to conduct CMRT surveys and 1,534 of 1,581 suppliers that we asked to conduct EMRT surveys (as of March 31, 2025; excludes surveys conducted by Panasonic Automotive Systems Co., Ltd.). Based on the data collected from the survey forms, we conducted a risk analysis and assessment and requested further investigations from suppliers, according to the risks that we identified.

In fiscal 2025, roughly 60% of the designated refiners and smelters had Conformant/Active Smelter status (refiners and smelters that have either passed RMI audit or is currently undergoing one). We are also working on industry efforts that will push the remaining 40% of those refiners and smelters toward participation in the Responsible Minerals Assurance Process (RMAP). In the rare event that we find minerals that are complicit in conflicts or human rights violations in our supply chain, we also ask suppliers to take steps toward no longer using them, including changing their source.

▪Initiatives to Comply with the European Battery Regulation Due Diligence Requirements

Recent years have brought growing societal expectations that companies will responsibly source the raw materials used in batteries. In August 2023, the EU Battery Regulation (Regulation 2023/1542) came into effect. In response, the Group is conducting due diligence on environmental and social risks in the battery supply chain, as required by the EU Battery Regulation.

In fiscal 2025, we sought advice from external experts to deepen our understanding of these requirements. Furthermore, we received support from external organizations to conduct investigations with due consideration to the target companies’ business confidentiality and competitive concerns. We identified the chain of custody for the four target materials, assessed the risk levels of the entire battery supply chain, and collaborated with business partners (including parts and materials suppliers, manufacturing contractors, trading companies, and logistics companies within the battery supply chain) to evaluate their environmental and social risks and risk management systems. We plan to promote initiatives based on future guidelines for battery due diligence.

Internal Training and External Awareness-Raising

In order to develop human resources who can fulfill their social responsibilities in procurement operations, the Procurement Division provides training on CSR and procurement compliance to our procurement staff. We have established a buyer certification program to certify buyers who have acquired the necessary knowledge and skills, including CSR procurement, with over 1,500 participants having completed the Level 2 CSR procurement training required for certification. We have also conducted training for procurement employees overseas (in parts of Europe, the US, China, and other Asian countries). Through this training, we aim to consolidate their knowledge while confirming their understanding of essential topics and the importance of compliance in CSR procurement—including compliance with environmental, anti-corruption, and anti-bribery regulations, as well as human rights, labour, health and safety, and clean procurement in the supply chain. In addition to all this, we also build in basics on CSR procurement in our training curricula for new employees in procurement departments and those transferring from other divisions.

In fiscal 2024, we also conducted training programs to develop supplier auditors, holding two sessions in Japan, seven in Asia, and two in China, totaling 11 sessions. We continued these efforts in fiscal 2025 across 13 countries, training a total of 270 global auditors.

Our web portal for procurement employees contains the information necessary for responsible procurement— including the procedures employees should follow for CSR procurement, the CSR Self-Assessments we ask suppliers to conduct, and guidelines for conducting audits—so that employees always have the latest information when performing their duties.

In fiscal 2023, we looked to raise awareness in the supply chain by holding workshops and meetings with about 100 suppliers, mainly in Malaysia. We also conducted CSR audits at around 50 suppliers in Asia. In fiscal 2024, we held human rights due diligence training in Malaysia six times in cooperation with the United Nations Development Programme (UNDP), and 207 of the approximately 500 suppliers in Malaysia with significant transaction amounts (228 attendants) attended the training. In fiscal 2025, we explained the importance of ESG initiatives and conducted training for suppliers in Malaysia, India, Thailand, and Vietnam, targeting 280 to 630 companies per country. In fiscal 2026, we plan to expand our supplier training to Singapore, Indonesia, the Philippines, and other countries.

Systems for Whistleblowing and Seeking Consultation

The Panasonic Group has established its “Global Hotline EARS” that anyone, including Panasonic Group employees and suppliers, can use to anonymously report any violation or suspected violation of laws and regulations, agreements with our suppliers, the Panasonic Group Code of Ethics & Compliance, or other material codes in the Group’s supply chain. Whenever there is a report, the Group follows all internal rules and guidelines as well as the laws of the relevant countries with regard to the protection of the individual making the report, and from there it undertakes appropriate investigations and countermeasures. For more details, please see “Whistleblowing System” in the “Compliance”.

In addition to our Global Hotline, we offer access to JaCER, an industrywide grievance platform established by the CSR Committee of the Japan Electronics and Information Technology Industries Association (JEITA). JaCER is a contact point for suppliers and their employees to report any adverse human rights impacts in the Group’s supply chain. By accepting grievances through a third-party contact, we aim to make grievance handling fairer and more transparent, promote dialogue and redress more than ever before, and work to resolve essential human rights issues. In all reporting systems, we ensure whistleblower anonymity and report confidentiality and publicize the contact information for reporting systems on our supplier web portal and our website, “For Suppliers.”

We conducted audits through a third-party organization on human rights issues at suppliers that we received through the hotline, and we have witnessed suppliers take corrective actions.