Raising Product Quality Levels and Ensuring Product Safety

Based on the idea promoted by our founder that Panasonic should strive “to contribute to society through its products and services while always placing the customer first,” the Panasonic Group approaches “quality” as something that means more than the quality of the work we do or the products we make. To us, it also means conducting business in a fair and honest manner at all times, so that we can continue to offer products and services that are better than anyone else’s while upholding our commitment to our customers and society, taking action to ensure the safety and quality of our products and services.

Policy

Panasonic states in its Groupwide Quality Policy that the company will “truly serve customers by way of providing products and services that continuously meet and satisfy the needs of customers and society.” Each operating company has established and operates their own quality management system with responsibility for the quality of their products. In particular, our approach to quality defects focuses on compliance with laws, regulations, and corporate ethics, as stated in the Panasonic Group Code of Ethics & Compliance. This code specifies our adherence to laws, regulations, and social norms, including industry standards and promises to customers. It also states in Chapter 4: Our Business Relationships that we should honor our commitments to our customers and to society as they relate to our products and services, and that we must act in the interest of ensuring the safety and quality of our products and services. In addition, the Group has established a Basic Policy regarding the Voluntary Action Plan for Product Safety. As per this policy, Panasonic actively strives to ensure the safety of its products, while keeping to its principles of “the customer comes first” and of maintaining a “Fairness and Honesty” attitude.

Per our Basic Management Policy, Panasonic Group considers always ensuring the safety of the products we manufacture and sell and delivering safety and security to our customers as essential management issues and social responsibility objectives. Based on the profound lessons learned from the accidents involving FF-type kerosene heaters, specifically, we apply our unique product safety standards to each product lifecycle phase (from planning and design to service and disposal) for every product to ensure its safety at all times. We also use our Group intranet to share information related to the product safety of all Panasonic products in a timely manner to all employees, including persons in charge of quality and design at each operating company and business site. We also strive to fulfill our imperative of having zero product safety incidents.

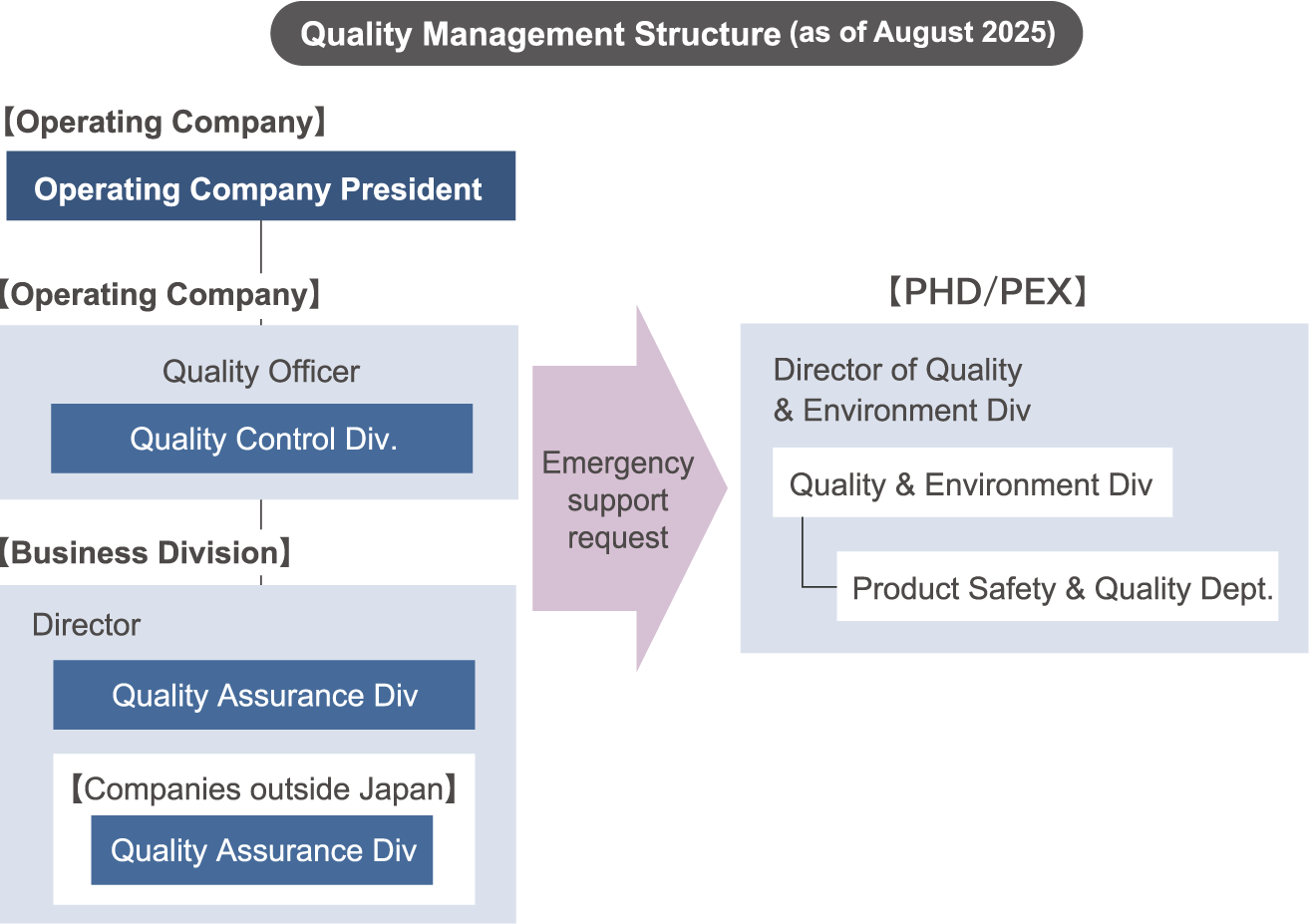

Responsible Executive and Framework

As of August 2025, the executive in charge of quality is the Group Chief Technology Officer (Group CTO). Each operating company has appointed a quality manager and established systems for undertaking its business with independent responsibility and self-sufficiency. In addition, Panasonic Holdings Corporation (“PHD”) and Panasonic Operational Excellence Co., Ltd. (“PEX”) provide support in response to the requests from the operating companies as countermeasures against critical risks for the Group, while expanding quality-related assets horizontally over the Group.

▪Quality Policy Review Structure (Meetings and Committees)

Panasonic Group investigates and summarizes Groupwide quality improvement efforts and the state of product quality within the Group at its Chief Quality Officer (CQO) Meetings. Group CQO, CQOs from each operating company, and persons involved in relevant job functions such as quality and product regulations attend these meetings. Attendees discuss how we should handle quality over the medium and long terms, and they decide on initiatives meant to further strengthen the foundation of quality for the whole Group. Panasonic Group also holds the Quality Committees— attended by the quality managers of each operating company—as a place for more practical discussions on quality policies and measures.

Quality Management System

To establish self-sufficient quality assurance processes in each operating company and business site, Panasonic Group published its Product Quality Management System (P-QMS) Guidelines in 2004. These Guidelines supplement the requirements of the ISO 9001 standard with the Group’s own quality assurance methods and expertise to create a quality management system and have been updated to comply with ISO 9001-2015. Operating companies and business sites work to implement quality management systems uniquely tailored to their business characteristics with reference to these Guidelines. At various levels, they conduct regular quality assessments and quality audits to review the progress of quality management while also formulating corrective action plans for any discovered deficiencies, all in an effort to continuously improve quality.

To properly address our continually diversifying business areas, each operating company operates according to the P-QMS Guidelines and industry standards appropriate to its field, from household appliances, in-vehicle accessories, residential, devices, B to B solutions, pharmaceuticals, services, and more.

In addition to quality audits at operating companies/ business sites, the PEX Audit Department and the Quality Department jointly conduct quality function audits against operating companies (including against specific products) for the purpose of strengthening periodic second-party audit perspectives on products. We evaluate various processes in the development and manufacture of products, and work to understand the effectiveness of our operating companies/business sites’ quality management systems. Additionally, we obtained and maintain quality certifications (ISO 9001/ IATF16949) at our operating companies and production sites. Regularly incorporating audits by third-party organizations enhances checks on each process—including development, manufacturing, and inspections—and improves our reliability to our customers.

Meanwhile, due to instances of irregularities for electronic materials products manufactured and sold by Panasonic Industry Co., Ltd., the international standards for quality management systems “ISO 9001” and “IATF 16949” of the affected business sites have been revoked in March 2024 and May 2024 respectively. We will continue to work on improvements with the aim of obtaining recertification for both standards. Please refer to the “Compliance” chapter for information on how the irregularities have been handled.

Global Safety Standard Certifications Obtained

▪ISO 13849 (ISO 13849-1) Certification

An international standard issued by the International Organization for Standardization (ISO) that applies to parts of machinery control systems responsible for providing safety functions. Panasonic Advanced Technology Development Co., Ltd. received recognition in March 2024 that its wireless emergency stop device (receiver) is compliant with the international standard ISO 13849-1 Safety of machinery - Safety-related parts of control systems.

▪NSF/ANSI/CAN 372 Certification

NSF/ANSI/CAN 372 is an international standard for the safety of drinking water used in the United States, Canada, and internationally. This standard establishes criteria for lead content in drinking water supply fixtures. The drinking water system components in Panasonic HVAC Company’s heat pump water heater were recognized as compliant with this standard in fiscal 2025.

▪EN 18031 (EN 18031-1 and EN 18031-2) Certification

EN 18031-1 and EN 18031-2 are standards that meet the cybersecurity requirements of the European Radio Equipment (RE) Directive. The former establishes common security requirements for wireless devices connected to the Internet, while the latter addresses data protection and privacy requirements. The network adaptor in Panasonic HVAC Company’s heat pump water heater was recognized as compliant with these standards in fiscal 2025.

Internal Company Rules Concerning Product Labeling

Based on the Manufacturing Industrial Standards for Panasonic Group, each operating company determines its own approach and guidelines to be followed with regard to the way their products are handled as well as installation and services as appropriate for each product. Specifically, warning label related to the safe use of products and information label on legally designated recycling or disposal methods (according to the laws including Recycling Acts) and other information that helps customer safely use our products and services are specified in the design methods of warning labels and instructions for use, care and installation of products in consideration of preventing customers from misusing. There have been no instances of product labeling violations subject to fines or penalties in the Group (as of August 2025).

Product Security

As consumers conveniently use various products equipped with software and connected with networks, we must ensure product security to prevent harm from attacks initiated by malicious third parties who aim to leak or alter data or cause device malfunction. Panasonic establishes internal structure and rules, including a specialized department for Groupwide product security and guidelines for promoting security-conscious development. We ensure the security of our products by regularly reviewing the structure and rules in conjunction with our information security and production system security initiatives, so our customers have peace of mind when using our products.

▪Ongoing Information Collection

Product security issues and how to address them change on a daily basis. At Panasonic Group, we collect the most up to date information on product security by joining various security focused organizations, e.g., FIRST*, a forum to share information on security incidents, and attending various global conferences. This information is shared with any relevant divisions and used internally through initiatives to improve product security measures throughout the Group.

* FIRST: Forum of Incident Response and Security Teams

▪Promoting Product Security from Development

During the development phase of a product, we consider what assets and functions need to be protected, as well as any potential attacks against them. Products are developed while minimizing these risks. In addition, security experts perform tests incorporating up-to-date attack methods on the product prior to shipment, to ensure that Panasonic products do not contain any “security vulnerabilities” from both a hardware and software standpoint.

▪Post-shipment Response

As part of the Group’s post-shipment monitoring of our products, we have a contact point to receive reports on vulnerabilities discovered in Panasonic products after shipment. When we receive information on vulnerabilities, we immediately verify whether they will impact Panasonic products. If we find that our products have security issues because of those vulnerabilities, we ensure product security through updates or similar means and take additional actions including establishing a check system to prevent the issue from recurring. We have systems in place that allow the Product Security Center to monitor progress and provide support until the response of the relevant business divisions are complete.

We also have systems in place that make it possible for Panasonic to take a more active role in obtaining information on vulnerabilities and acting on it (rather than waiting for vulnerabilities to be reported) by continually monitoring the latest threats that might affect our products post sale.

Major Accidents and Responses

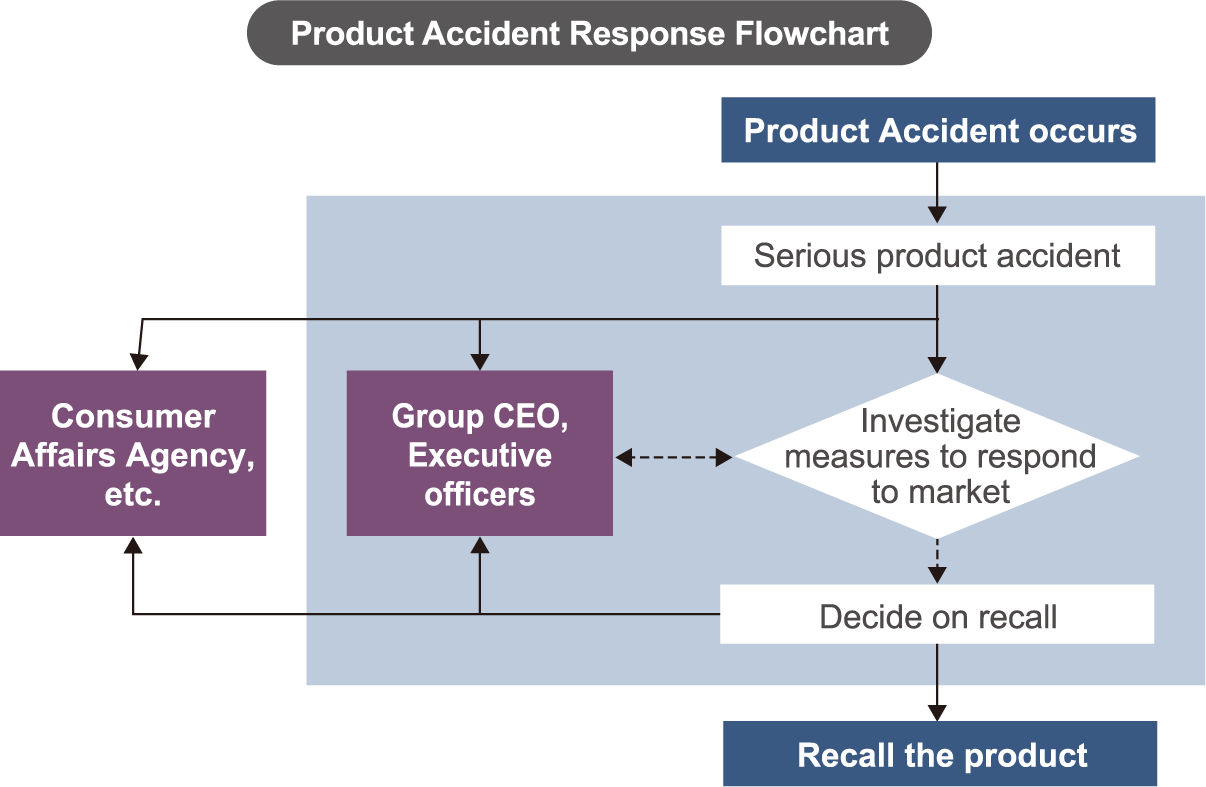

▪Responding to Product-Related Incidents

In the event that a product-related accident occurs, Panasonic immediately confirms the facts related to the incident, and analyzes and verifies its causes. If the incident is deemed to be serious, operating companies and business sites as well as PHD/PEX work together to take appropriate measures to ensure customers’ safety. Specifically, Panasonic Group’s first response is to notify relevant government bodies such as the Consumer Affairs Agency, as well as the operating company President, Group CEO and senior management, who then consider the response policies. In addition, based on incidents that have occurred in the past, operating companies prepare manuals detailing responses to product failures, safety test documentation, etc. We are putting these into practice in new product development, specification changes, etc. to prevent incidents’ recurrence.

▪Serious Product-Related Accident Information

In Japan, Panasonic Group publicly reports serious product accidents*1, including accidents suspected of being caused by products*2, and accidents for which it has been determined that it is unclear whether a product was the cause*3, based on the Consumer Product Safety Act and the Group’s basic policies per its Autonomous Code of Conduct for Product Safety.

*1 “Serious product accidents” refers to the following accidents specified in the Consumer Product Safety Act:

- Accidents resulting in death;

- Accidents resulting in serious injury or illness (injury or illness requiring at least 30 days of treatment), or accidents resulting in physical impediment;

- Carbon monoxide poisoning;

- Fires (confirmed as such by firefighting authorities).

*2 Any of the following:

- Accidents relating to gas devices or kerosene devices (including accidents in which it has yet to be determined whether the product was the cause);

- Accidents relating to products other than gas or kerosene devices for which it is suspected that the product was the cause.

*3 Among serious product accidents, accidents for which Product Safety Group of the Consumer Economic Affairs Council of the Ministry of Economy, Trade and Industry, Japan, has determined that it remains unclear whether a product was the cause.

Outside of Japan, Panasonic also identifies and discloses information on product-related accidents based on the laws and guidelines of each country.

▪Progress in Response to Incidents Related to FF-Type Kerosene Heaters

It has been 20 years since Panasonic undertook emergency groupwide market measures as a result of product safety incidents involving FF-type kerosene heaters in 2005. We continue to work, led by the Corporate FF Customer Support & Management Division, to prevent any new incidents.

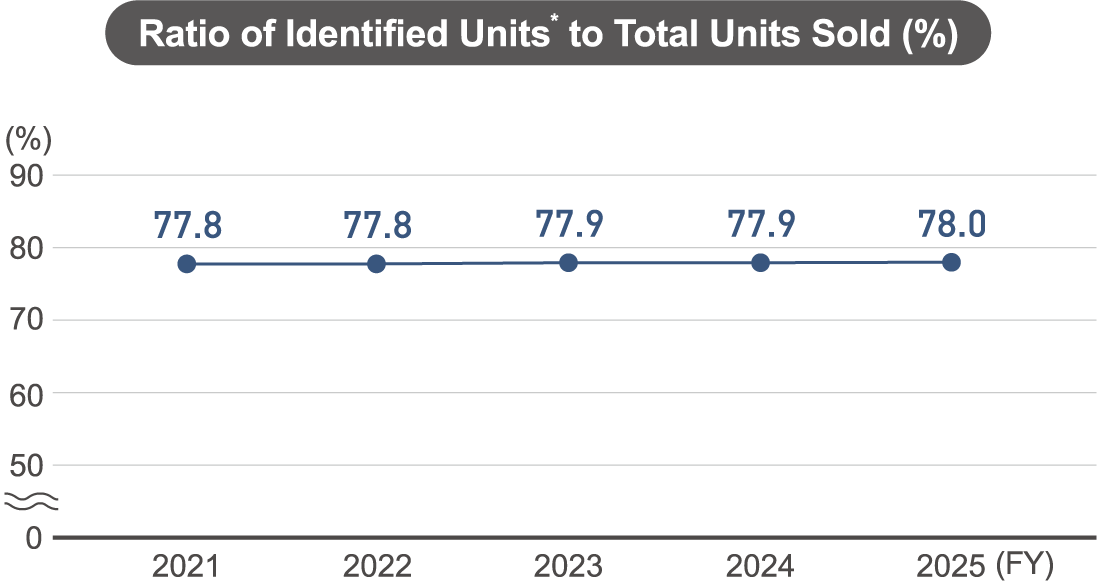

In fiscal 2025, as part of our efforts to identify target products, we conducted a door-to-door survey of exhaust and intake ducts in the vicinity of former retailers that have ceased operations, focusing on Hokkaido, Tohoku, and Nagano Prefectures. The same year, we began utilizing IT-based investigation tools to drive the search toward new discoveries. Furthermore, we continue to diligently promote product recalls from customers who have already had their units inspected and repaired, while also maintaining ongoing notification campaigns to ensure that all customers are informed of the recall. In fiscal 2025, we added 56 units to our list of products discovered or confirmed to have been discarded. In total, 118,642 units have been recorded, representing 78% of the units sold as of March 31, 2025. We were finding products that our customers had continued using without realizing the potential harm of the heaters, meaning that a high degree of risk still remains. We will continue our search efforts.

* Identified units: This figure includes the number of units recalled, the number of units in use after examination and repair, and the number of units we have confirmed that customers have discarded.

Training

The Panasonic Group conducts training every year for all quality managers at each operating company and business site, with the aim of training key quality personnel to promote quality management innovation. In particular, the Group regularly holds a Business Division Director Quality and Environment Workshop for business managers responsible for the quality management systems in their respective divisions, as well other activities geared toward learning about results-driven, quality-based management, including guest lectures and training through case studies. In addition to training for specific employee ranks, we are promoting awareness of group-wide quality improvement through ongoing quality training for quality function employees during the first three years after joining the company, as well as customized training specific to products and businesses.

In addition, e-Learning programs such as “Fundamentals of Product Safety” are being put in place to spread a corporate culture that places the highest priority on product safety to all employees. In addition, each operating company conducts its own Quality Control (QC) Activities through which individuals can come together to learn problem solving methods to be used in the field as part of our efforts toward bolstering quality on the production floor. Product Safety Forum, an event that provides a venue for thinking about product safety using examples from the Group and elsewhere, took place twice in fiscal 2025, for a total of 85 times.

The Group has also established a Product Safety Learning Square at the Team & Talent Development Center in Hirakata, Osaka, with the aim of conveying lessons based on actual business sites and actual products, and of providing instruction to enhance product safety-related skills. The Product Safety Learning Square offers an opportunity to see actual products that were recalled in the past—such as those recalled after the FF-type kerosene heater accidents—as well as other information on the causes of their problems, the steps taken during the recall, and the measures taken to prevent the critical unsafe phenomena (including tracking or strength degradation). The Virtual Product Safety Learning Square also provides an online exhibition that can be viewed freely online. The Product Safety Lab recreates an actual space that was filmed in 360 degrees to allow viewers to move around that space freely, and even read information panels or watch views by simply clicking on an icon. We also conduct educational activities for employees in distant locations and outside Japan by expanding our reach.

We also pass down the lessons learned from customer safety incidents, especially those involving FF-type kerosene heater accidents, through lectures given in various training programs and educational materials posted at the aforementioned Hirakata Product Safety Learning Square, the Kusatsu Product Safety Museum, the Nara Learning Center, and the Mobile Learning Center. We strive to foster a Panasonic Group culture that prioritizes product safety. As we mark the 20th year since the accidents, we have updated the exhibitions in Hirakata and Nara to raise awareness of what happened and to demonstrate our top management’s commitment to quality, as well as promote behavioral changes aligned with our “customer-first” philosophy. Key updates include revisions to the content and layout of the FF-type kerosene heater accident exhibition, as well as the addition of a new Quality Compliance Zone.

List of Awards

▪Product Safety Awards

The awards program was launched by the Ministry of Economy, Trade and Industry in 2007 with the aim of encouraging private enterprises to be more active about improving product safety, as well as to firmly establish the value of product safety in society as a whole.

▪IAUD International Design Award

The awards program was created by the International Association for Universal Design and is meant to recognize groups and individuals who have conducted or proposed particularly noteworthy activities aimed at realizing a UD society in which everyone can live comfortably. Various products and initiatives of former Panasonic Corporation had received the IAUD Gold Award for seven consecutive years until 2018, in addition to other recent recognition below:

- FY2021

Panasonic LED Torch Light, Silver Award, Innovation for Everyday Use and Emergency Situations First Shaving Series, Bronze Award, Product Design - FY2022

Panasonic IC card reader with facial recognition, Gold Award, Healthcare and Welfare Design Emergency broadcasting equipment, Silver Award, Security and Public Safety - FY2025

Panasonic’s Inclusive Design, Grand Award (Business Strategy category) at IAUD International Design Award 2024