Mid-term to Long-term Environmental Vision

Future Vision of the Panasonic Group and solutions to global environmental issues

The true mission of the Panasonic Group is to achieve both of 'material and spiritual prosperity', in other words 'an ideal society with affluence both in matter and mind' that is pursued by our founder Konosuke Matsushita in his entire life. In 1932, the founder declared his ambition to create an ideal society over a span of 250 years. Since then, taking over the founder's ambition, we have solved social issues by manufacturing useful products and providing useful services, etc., while seeking for happiness of individual customers.

At present, the biggest obstacles preventing us from achieving our mission are global environment issues. In order to reduce depletion of limited natural resources and urgent problems caused by climate change or global warming as much as possible, it is indispensable to take actions to realize a carbon-neutral society (limiting the increase of global temperature to less than 1.5°C) and circular economy business systems. Panasonic has acted promptly to fulfill our corporate responsibility and contribution (ACT). Based on our strong determination to lead to solutions, we announced the Group's long-term environmental vision "Panasonic GREEN IMPACT (PGI)" that leads to achieve much greater contribution to definitely solve such problems in January 2022.

Under the Vision, we have accelerated our activities to reduce environmental loads through our value chains, and at the same time, to contribute to reduce CO2 emissions discharged from society and customers.

As a part of resource depletion countermeasures, we announced the Circular Economy (CE) Group Policy (see previous page) in November 2023—both inside and outside the company.

Through the Policy, we set out the foundations of business management as our contribution to building a sustainable and economically social system from the perspectives of corporate-led innovation and social system reform. The Policy helps us to identify CE-related issues according to business characteristics, as well as to plan and implement CE strategy.

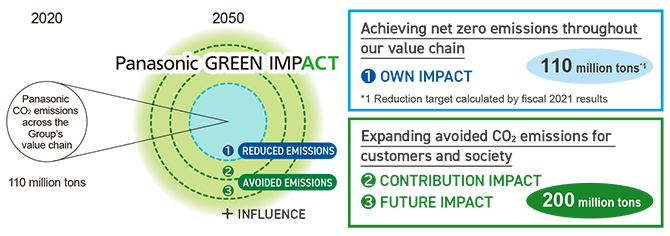

Panasonic GREEN IMPACT

PGI is the Panasonic Group's overall vision for our environmental strategies with an eye on the business reforms to be completed by 2050 in order to achieve both "better lives" and "a sustainable global environment." PGI comprises different fields of CO2 emissions reduction efforts.

❶ OWN IMPACT refers to efforts within our own value chain, ❷ CONTRIBUTION IMPACT and ❸ FUTURE IMPACT are extended effort of contribution, and + INFLUENCE is the positive impact on customers and society. PGI states that, through the above ❶, ❷, and ❸ actions, by 2050, we aim to create an impact that reduces CO2 emissions by at least 300 million tons*2 per year, equivalent to approximately 1% of global CO2 emissions (31.7 billion tons) in 2020.

*2 Based on the total energy-related CO2 emissions of 31.7 billion tons in 2020 (source: IEA), when PGI started.

The emissions factor of avoided CO2 emissions is based on the data of 2020.

❶ OWN IMPACT (Reduced CO2 emissions compared with fiscal 2021)

We aim to achieve net zero CO2 emissions within our own value chain*3 (110 million tons*4), along with the effect of the broader decarbonization of society*5.

*3 Total of CO2 emissions from our business activities (Scopes 1 to 3) including emissions from our operating companies (Scopes 1 and 2), emissions from manufacturing components and materials (Scope 3, Category 1), and emissions in product use (Scope 3, Category 11) (Please refer here)

*4 Fiscal 2021 actual results

*5 Improvement in CO2 emissions factor for electricity by respective electric power suppliers.

❷CONTRIBUTION IMPACT (Avoided CO2 emissions in present business fields*6)

We aim to achieve avoided CO2 emissions of at least 100 million tons per year among customers and society by 2050 through our present business fields.

❸FUTURE IMPACT (Avoided CO2 emissions by creating new technologies and businesses *6)

We aim to achieve avoided CO2 emissions of at least 100 million tons per year among customers and society by creating new technologies and businesses.

*6 Amount of our contribution as CO2 emissions reduction to society and customers through using our products and services (Please refer here).

+ INFLUENCE (Positive ripple effect of energy reform and decarbonization of society)

We aim to provide a positive influence on society by changing the behavior (ACT) of a wider range of people through the Panasonic Group's products, services, and social communications.

We will accelerate energy demand stabilization and decarbonization through our contribution to behavioral changes in our customers, business partners, governments, and investors. Initially, we will undertake action from within our group, as a part of the PGI initiative.

Environmental Action Plan "GREEN IMPACT PLAN"

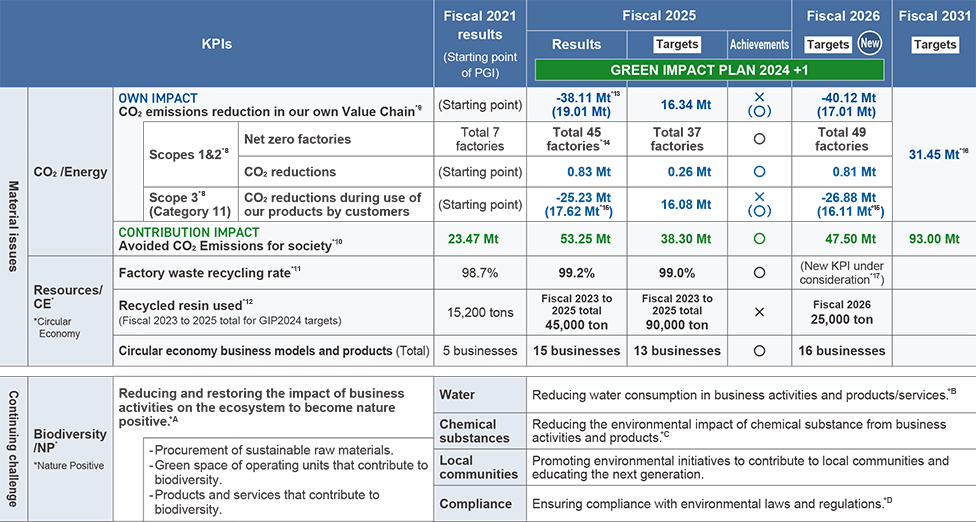

As a milestone to achieve Panasonic GREEN IMPACT (PGI), we created and published the GREEN IMPACT PLAN 2024 (GIP2024) that sets out our groupwide environmental actions from fiscal 2023 to 2025, along with fiscal 2031 targets. We are keenly following this plan.

GIP2024 specifies a range of priority issue KPIs*7 including those for OWN IMPACT, the number of net zero factories, CONTRIBUTION IMPACT, factory waste recycling rate, expansion of recycled resin use, and the number of new circular economy business models.

Also, we continue working on issues related to biodiversity & Nature Positive (NP), water, chemical substances, local communities, and legal compliance, according to the characteristics of business fields and regions. This is because we understand the importance of addressing social issues and gaining the trust of society and customers concerning the Panasonic Group's actions. For details of each KPI and target, effort details, and results, see the table on the right and referenced pages.

*7 Key Performance Indicators (KPIs) are figures to quantitatively evaluate and analyze progress towards achieving the PGI targets.

Priority Issue KPIs and Targets

The Panasonic Group has been reforming our methods of group management to ensure sustainable growth. We plan to start a new mid-term strategy under the new structure from fiscal 2027 (announced in February 2025). As PGI is linked to business growth, we continue our environmental initiatives by setting single year targets(GIP2024+1) as an extension of the current GIP2024 for fiscal 2026. We have been stably achieving a factory waste recycling rate of 99% or more over the last three years. We are now considering to set a new KPI for the next mid-term plan, to align with international trends.

The new plan will be updated seamlessly with new business strategies. We are constantly refining our efforts to build a sustainable society during the period specified in the next mid-term plan.

GREEN IMPACT PLAN 2024 Targets and Actual Results, Fiscal 2026 Targets (GIP2024+1) and Fiscal 2031 Targets

*8 Classification according to the GHG Protocol (Accounting and Reporting Principles).

*9 Amount obtained by subtracting the amount of emissions in the relevant fiscal year from the amount of emissions in fiscal 2021.

*10 Amount calculated by subtracting the lifetime CO2 emissions after introduction from the lifetime CO2 emissions assuming that the Group's products and services do not exist, using the IEC 2021 value as the emission factor.

*11 Amount of resources recycled / (Amount of resources recycled + Amount of landfill).

*12 Mass of recycled materials contained in the recycled resin used in our products.

*13 Minus sign (-) means increasing emissions. Including increases or decreases in Scope 1,2 and Scope 3 Category 11, Category 1 (procurement), Category 12 (disposal), and other indirect emissions. The figures in the parenthesis is a comparison with fiscal 2021 results (starting point) reflecting the equivalent amount of emissions from the products whose calculations became available after 2021.

*14 Excluding Panasonic Automotive Systems Co., Ltd.

*15 Amount of CO2 emissions reduction since fiscal 2021, calculated with the 33 target businesses in Category 11 in fiscal 2021.

*16 The CO2 emissions factor for electricity calculated with the IEA World Energy Outlook's 2°C scenario.

*17 Because the waste recycling rate remains at a high standard of 99% or more, we will exclude this from the fiscal 2026 targets and set a new KPI that matches current global trends.

※A Reducing and restoring the impact of business activities on the ecosystem to become nature positive.

※B Reducing water consumption in business activities and products/services.

※C Reducing the environmental impact of chemical substance from business activities and products.

※D Ensuring compliance with environmental laws and regulations.

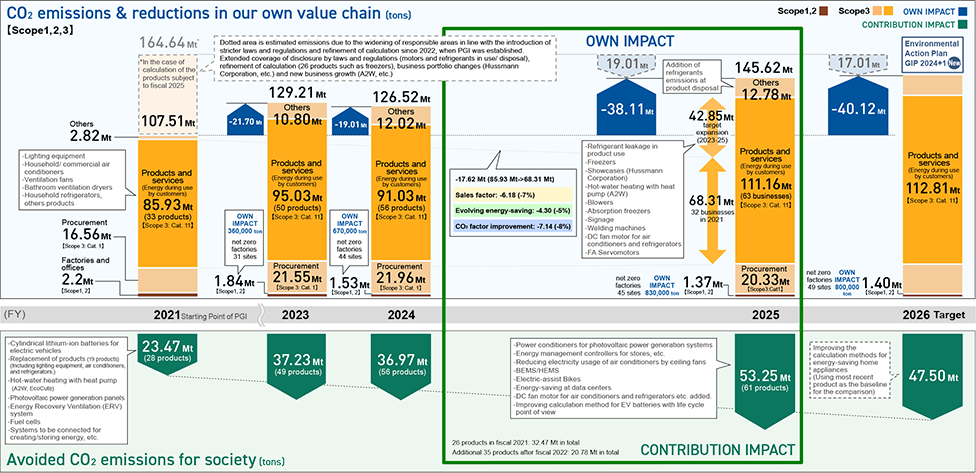

Fiscal 2025 Results of CO2-related KPIs

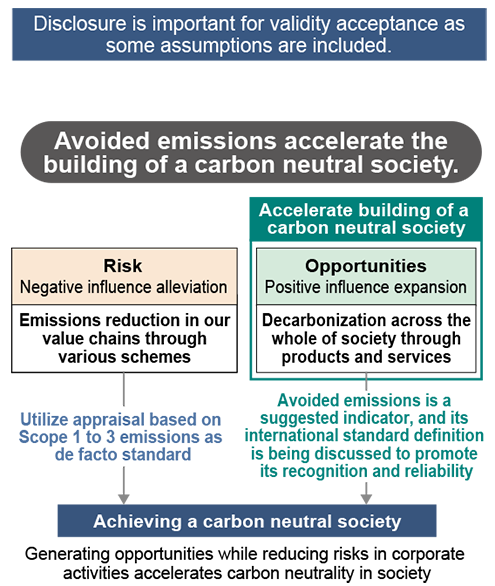

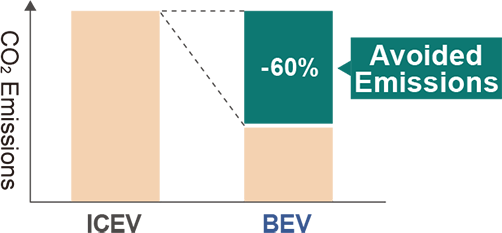

CO2-related KPIs, including those for OWN IMPACT, CO2 emissions, net zero factories, and CONTRIBUTION IMPACT (avoided CO2 emissions), are core PGI indicators to achieve net zero CO2 emissions across our value chains and for our cooperative efforts toward carbon neutrality together with customers and society. Emissions and avoided emissions are both CO2-related indicators, but their calculation methods and usage are different. Emissions (upper part of figure) are an indicator representing the amount of CO2 we need to reduce in our value chains.

On the other hand, avoided emissions (lower part of figure) represent the amount of CO2 emissions reduction from our customers or in society through our businesses that contribute to decarbonization.

CO2 emissions from our own value chains cannot be offset or reduced by the avoided CO2 emissions. These two indicators are two sides of the same coin, and at the same time, two pillars of our business activities. We are expanding and accelerating our emissions reduction impact through closely coordinating our efforts under both indicators.

CO2 Emissions (Upper part of figure)

Scopes 1 and 2 emissions (CO2 emissions from energy use in factories, etc.) in fiscal 2025 amounted to 1.37 million tons thanks to further introduction of energy-saving activities and renewable energy use. CO2 emissions from using our products (Scope 3 Category 11) account for 70–80% of the total emissions in our value chains, and these emissions from 33 products marked 85.93 million tons in fiscal 2021, when we started PGI. This figure grew to 111.16 million tons in fiscal 2025, because the business coverage expanded to include 63 products.

The expansion of Scope 3 coverage (dotted area in the bar graph) was due to the widening of responsible areas in line with the introduction of stricter laws and regulations, growing social demands, and increase of strategic importance since 2022, when PGI was established. Contributing factors to this expansion include business growth, business portfolio changes and expansions (freezers, A2W, acquisition of Hussmann Corporation, etc.) and extended coverage of disclosure (e.g. CO2 emissions from motors and refrigerants).

Since the announcement of PGI in 2022, we have been gaining an understanding of the appropriate recognition and identification of areas subject to Scope 3, and improving the accuracy of our calculations. In GIP2024+1 that we set for fiscal 2026, we will revise the starting point of OWN IMPACT so that our efforts are appropriately evaluated while maintaining the current framework.

When we focus on the emissions from the 33 businesses covered in fiscal 2021, the total emissions in fiscal 2025 were 68.31 million tons, which marks a reduction of approximately 20%. This reduction was achieved by several factors, including changes in sales volumes, evolution of energy-saving technologies, and improvement in the CO2 emission factor for electricity.

Avoided CO2 Emissions(Lower part of figure)

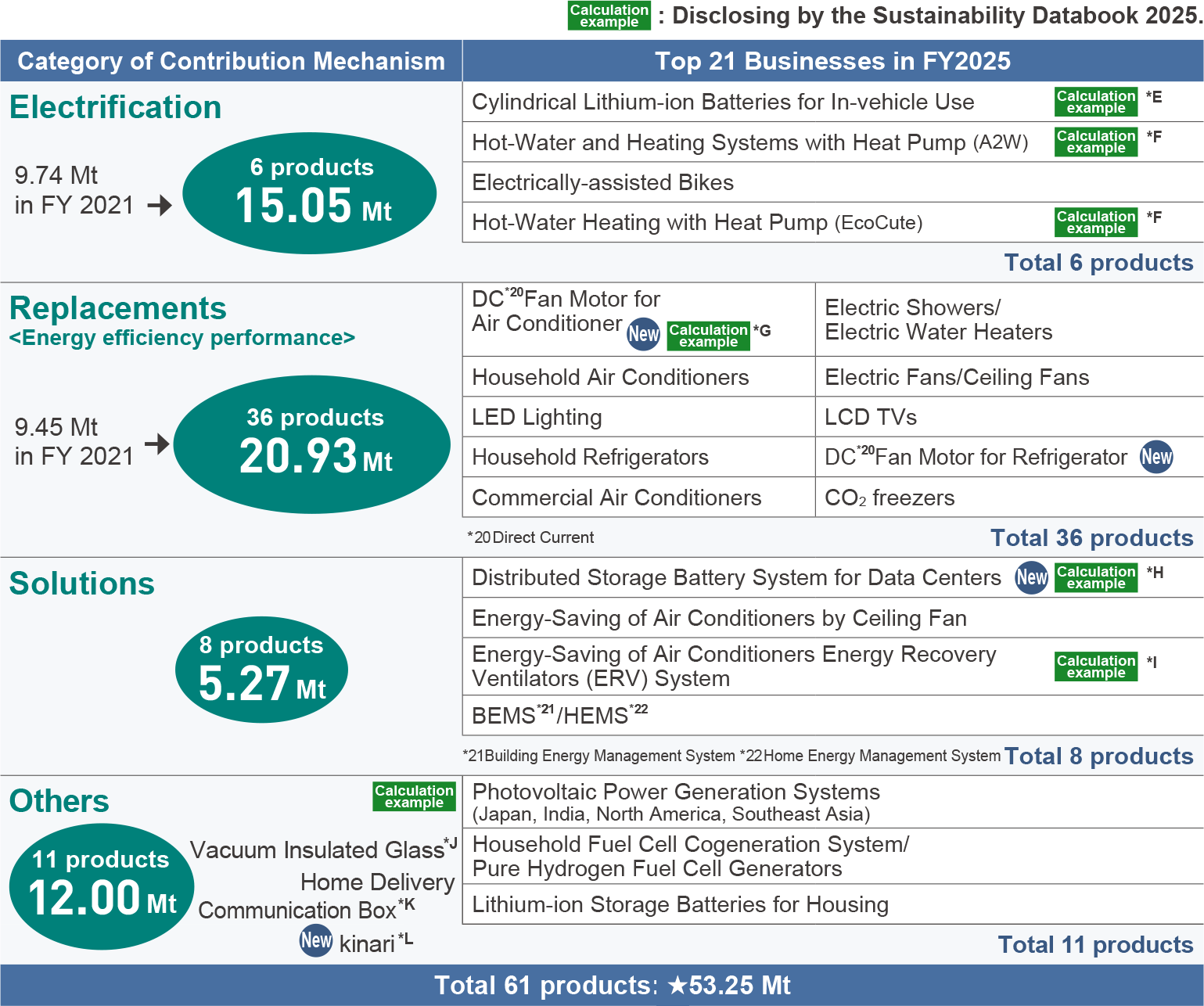

Avoided CO2 emissions (CONTRIBUTION IMPACT) by our products and services in fiscal 2025 was 53.25 million tons, which significantly exceeded the target figure of 38.30 million tons by 14.95 million tons.

The major contributors to this success were expansion of businesses that contribute to decarbonization, and inclusion of new products and services—a DC fan motor for air conditioners and refrigerators (Please refer here), and a distributed storage battery system for data centers (Please refer here). The number of products subject to CONTRIBUTION IMPACT has increased to 61 in fiscal 2025 from 28 in fiscal 2021.

In fiscal 2024, we altered the emission calculation method for the automotive lithium-ion cylindrical battery series, which generates the greatest avoided emissions in the Group, to a life cycle-based method for better accuracy (only the running time was used in the conventional calculation). This change lowered the avoided emissions volume per battery.

Regarding the calculation method for avoided CO2 emissions from new products with better energy-saving performance ("replacement" of products), we have used the hypothetical lifetime emissions of a conventional product to be replaced by the new product as the baseline for the comparison. We then use the difference in total emissions between the two as the figure for avoided emissions. From fiscal 2026, we will use emissions from the most recent market-average product as the baseline to comply with requirements for the international standard*18 for avoided emissions, which are currently under discussion. The fiscal 2026 target includes a reduction of approximately 9 million tons that proactively reflects the latest calculation methods, resulting in a reduction of approximately 10% year-on-year to 47.50 million tons.

*18 Please refer here.

GREEN IMPACT PLAN 2024: Status of CO2-related KPIs

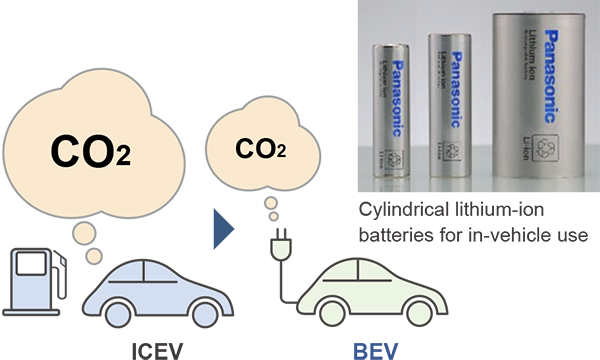

Avoided CO2 Emissions

Avoided CO2 Emissions (hereafter, avoided emissions) is an indicator of how much we contributed to reducing CO2 emissions (hereafter, emissions) from customers and society. We quantify this amount of contribution as KPIs of CONTRIBUTION IMPACT and FUTURE IMPACT according to the nature of the specific business (Please refer here).

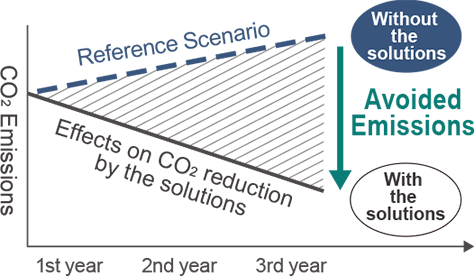

The amount of avoided emissions is calculated as the difference between before and after the introduction of a new technology, product, or service (hereafter, product), and refers to emissions across the product's entire life cycle, as well as from connected products and services. In the calculation, we set a hypothetical baseline scenario in which the new product is not introduced, and calculate the difference between emissions in the baseline scenario and those in the scenario where the new product has been introduced (emissions are not limited to the product's running time). When a company promotes the widespread use of its products, the emissions that would have occurred if the product had not been introduced are expressed as "Avoided Emissions."

The total emissions across a corporation's value chain (Scopes 1, 2, and 3) are calculated based on an international standard called the GHG Protocol. The reduced volume of emissions (reduced emissions) is calculated in this process. PGI's OWN IMPACT is equivalent to this reduced emissions (Please refer here). Reduced emissions and avoided emissions may appear similar, however, they are separate indicators with different purposes and different calculation methods. Avoided emissions cannot offset emissions from our own value chains.

Avoided emissions function as a quantitative indicator of the impact from a business provider or their solutions that contribute to the emissions reduction of other parties. By promoting use of this indicator for business appraisal and investment decisions, Panasonic aims to establish a fair way to evaluate decarbonization-oriented businesses and encourage competition.

CONTRIBUTION IMPACT through our products sold in fiscal 2025 reached a total of 53.25 million tons across 61 products. The figure was boosted by including data from eight more products. Our efforts for CO2 emissions reduction can be divided into the following four categories.

- Electrification: Electrified appliances and components that use energy more efficiently than those that use fossil fuels.

- Replacements (Better energy-saving performance): Products with same functional performance but better energy-saving.

- Solutions: Products that optimize power consumption throughout entire building spaces and facilities.

- Others: Various contributions other than above, such as clean power generation, building insulation.,etc

Definition of Avoided Emissions

(Note) Avoided emissions cannot be used to offset the emissions within the company.

The avoided emissions are defined as positive impact on society by a solution in terms of CO2 emissions reduction when comparing to those in the reference scenario where the solution is not used.

WBCSD, 2023/3, "Guidance on Avoided Emissions"

Along with the spread of renewable energy usage thanks to the efforts of energy suppliers (over-the-grid electricity suppliers in each area), improving energy efficiency is also important as it reduces the burden on electricity suppliers while encouraging further use of renewable energy. We contribute to improving energy efficiency in building spaces and infrastructure where our products are used—by means of avoided emissions. The concept of avoided emissions has existed for a while, although an international standard for its calculation method is still under discussion. Also, its recognition is still to develop in different areas of society, such as the financial sector.

Avoided emissions has yet to become an industry standard indicator as there remain issues to be resolved.

For example, the interpretation of the hypothetical calculation—that is, the calculation for the case where the energy-saving product is not introduced—varies in terms of methods and disclosure conditions. To bring avoided emissions to a global standard (Please refer here), Panasonic is developing a rational calculation method compliant with existing electrical standards, and actively disclosing the targets, results, and contribution details*19. As a part of these efforts, we renew the basic unit for reduction and baseline per product when we make our annual fiscal business plan. We will increase the competences of the businesses that contribute toward carbon neutrality, and aim at generating avoided emissions as much as possible through dissemination and long use of our products.

This is one way in which we are contributing to building a carbon neutral society.

*19 On the premise of presenting avoided emissions, we set emissions reduction targets across our entire value chains

(Scopes 1 to 3) in line with the 1.5°C scenario of the SBTi (Please refer here). We are currently working to achieve these targets (OWN IMPACT). We are also studying if there is any rebound effect as the products become widespread (as of now, we have not seen any rebound effect other than an increase in life cycle emissions due to the spread of products).

To ensure the objectivity of our calculation methods and evidence for the data presented in this report, they are verified by a third party before disclosure.

For further examples of our avoided emissions products that contribute to CO2 reduction for customers and society, see the following website.

CONTRIBUTION IMPACT

※E Cylindrical Lithium-ion Batteries for In-vehicle Use

※F Hot-Water and Heating Systems with Heat Pump (EcoCute, A2W)

※G DC Fan Motor for Air Conditioner

※H Distributed Storage Battery System for Data Centers

※I Energy-Saving of Air Conditioners Energy Recovery Ventilators (ERV) System

※J Vacuum Insulated Glass

※K Home Delivery Communication Box

※L kinari

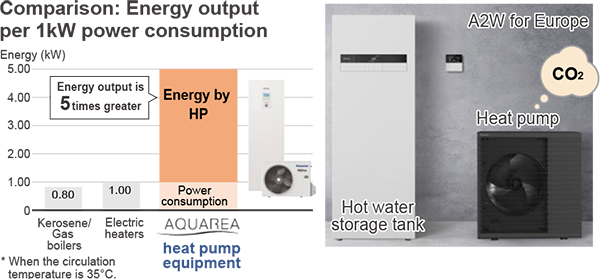

Hot-Water and Heating Systems with Heat Pump (EcoCute, A2W*23)

*23 A2W (Air to Water) : Air-to-water Heat Pumps for Europe

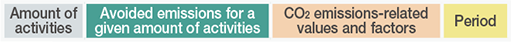

Main product life stages subject to avoided CO2 emissions

Sales regions: Japan for EcoCute, and Europe for A2W

Overview

A heat pump (HP) is equipped with electrification technology that captures heat energy from the ambient air and transfers it to heat water or air utilizing the characteristic that temperature changes when gas is compressed or expanded. With the technology, the equipment with heat pump is 2.4 to 4.3 times more energy-efficient compared to the equipment uses heat energy from fossil fuel combustion.*24 Furthermore, on the premise that the ratio of renewable energy use in each energy sources will increase year by year as the electrified equipment with heat pump is spread, whereas CO2 is always emitted from gas equipment in combustion of city gas, we will contribute to accelerate the transition to a decarbonized society.

*24 Our own calculation based on information in METI's 'Top Runner Program'.

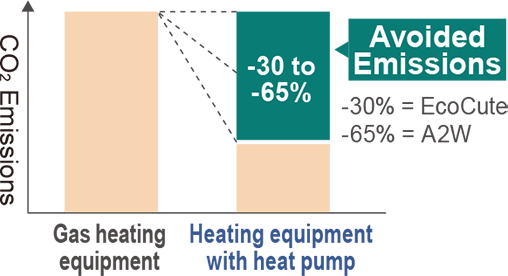

Avoided CO2 emissions mechanism

Our heating system, which uses a heat pump of equivalent capacity, emits less CO2 from the electricity used throughout its lifetime than the average gas combustion type hot water and heating system that is widely available in market.

Average CO2 emissions from water & air heating energy by one gas heating equipment and one heating equipment with heat pump.

Calculation formula of avoided emissions

![[ Amount of activities] (Units) The number of units that replaced existing gas heating equipment in the total annual sales volume*25 | *25 Japan: Approximately 70% of sales are heating equipment with heat pump replacing gas heating equipment. Europe: 100% of sales are heating equipment with heat pump replacing gas water heaters. | * (Annual city gas consumption per gas heating equipment (m3) * City gas CO2 emission factor (kg CO2 /m3) - Annual power consumption per unit of the heating equipment with heat pump (kWh) * Electric power CO2 emission factor per sales region (kg CO2 /kWh)) * Period (Ten years) | Annual avoided emissions by one heating equipment with heat pump replacing a gas heating equipment. | /Electric power CO2 emission factor: Japan 0.487 kg/kWh, and Europe 0.277 kg/kWh (Source: IEA 2021)/City gas CO2 emission factor: 2.240 kg/m3 Data from the Ministry of the Environment used globally.](/content/dam/holdings/global/en/corporate/sustainability/environment/vision/eco-vision_a_03.png)

Baseline (Subject to comparison)

CO2 emissions from combustion for the average gas water heater on the market in fiscal 2025*26 that produces the same amount of heat energy as when using a heat pump. Conventional gas by gas combustion is predominantly used in Europe where there are many cold climate areas. (Transformation of an A2W to its electrification is possible by using gas pipe used for the existing gas heating equipment.)

*26 From ANRE's Top Runner Program for Gas Water Heaters

Coverage of quantification (Concept and rationalization)

When the heating system uses a heat pump. Both heat pump systems and gas systems have a CFP*, and HP systems have a smaller CFP when they are not in use*27. However, it is small compared to the difference with the CFP when in use, so we decided not to add it to the Avoided emissions to retain a conservative viewpoint in the calculation.

*27 1 to 3% of the avoided emissions (actual results for Panasonic in FY2025)

Amount of activities (Unit)

EcoCute: The number calculated by the following equation: the annual sales volume in Japan x 70%*29 which is the replacement ratio of gas heating equipment with heating equipment with heat pump.

*29 Our own calculation based on data from the Japan Refrigeration and Air Conditioning Industry Association (JRAIA).

A2W: The number of annual sales of A2W in Europe (Unit)*30

*30 We deemed that replacement ratio of old A2Ws with new ones can be ignored as the sales started in 2008.

Avoided CO2 emissions per unit of amount of activities (Latest basic unit)

Regarding the annual energy consumption used for the same amount for heating water or air, which was converted to CO2 emissions, difference between those of heating equipment with heat pump and gas heating equipment.

Period (Flow method: Include entire lifetime CO2 emissions of the product in its first sales year)

The holding years of repair parts. CO2 emissions reduction effect continues during that period.

*CFP (Carbon Footprint of Products): CO2 emissions converted from GHG emissions throughout the entire product life cycle—from raw material procurement to disposal and recycling of a product and service (per one unit).

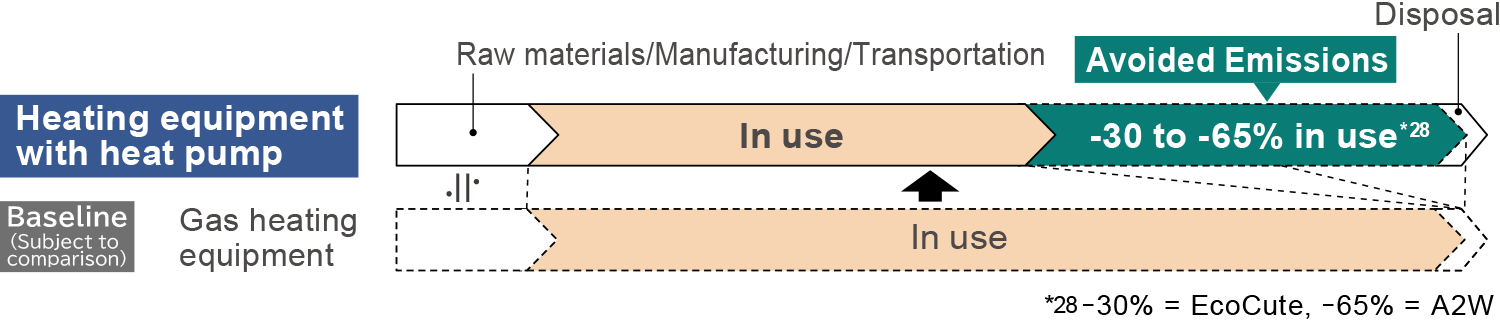

Cylindrical Lithium-ion Batteries for In-vehicle Use

Main product life stages subject to avoided CO2 emissions

Sales regions: North America

Overview

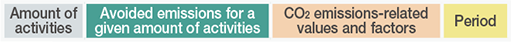

Transition from internal combustion engine vehicles (ICEVs) to electric vehicles (EVs) is expected to hasten decarbonization in transportation sectors all over the world as EVs, in addition to their energy efficiency advantages*31, emit only small amounts of direct CO2. In particular, Battery Electric Vehicles (BEVs) that do not use an internal combustion engine, employ a motor driven by electricity supplied from a rechargeable battery.

Thus the rechargeable batteries that are equivalent to the fuel supply function in an ICEV, are recognized as one of the most important components of the BEV.

*31 Energy efficiency: The percentage of consumed energy that reaches to the wheels; BEV: 87–91% ICEV: 16–25%.

Source: Yale Climate Connections. August,2022 "Electrifying transportation reduces emissions and saves massive amounts of energy"

Avoided CO2 emissions mechanism

In the case that a BEV and an ICEV with our rechargeable batteries installed drives the same distance, a difference arises between the amount of CO2 emissions converted from fuel consumed by the ICEV and the amount of electricity charged and discharged in the BEV because BEV's energy conversion efficiency to electricity is high.

CO2 emissions throughout the entire product life cycle of an ICEV and a BEV in the U.S.

Refer to ICCT (The international council on clean transportation)

Global-Vehicle-LCA-White-Paper-A4-revised-v2.pdf (theicct.org)

Calculation formula of avoided emissions

![[Amount of activities] (Units) The CO2 emissions converted from the number of BEVs of the battery capacity sold per year | Annual avoided emissions per travel distance for one BEV replacing an ICEV | *32 Not only during use of batteries (driving the vehicle), but also at every stage from the mining of raw materials needed for production, manufacturing, transportation, and disposal. | * (CO2 emissions for an ICEV throughout the entire product life cycle*32 - CO2 emissions for a BEV throughout the entire product life cycle*32) * Lifetime mileage(Average annual mileage respectively in Japan, U.S. and Europe x 10 years)](/content/dam/holdings/global/en/corporate/sustainability/environment/vision/eco-vision_b_03.png)

Baseline (Subject to comparison)

CO2 emissions for an average ICEV throughout the entire product life cycle including gasoline usage.

Coverage of quantification (Concept and rationalization)

The difference in total CO2 emissions for BEVs and ICEVs compared in emissions at each stage for rechargeable batteries or gasoline from mining raw materials, disposal, recycling and emissions during driving respectively.

Amount of activities (Unit)

CO2 emissions converted from the number of sold cylindrical lithium-ion batteries for in-vehicle use per year to the number of BEVs.

Avoided CO2 emissions per unit of amount of activities (Latest basic unit)

Difference in total CO2 emissions per travel distance throughout the entire life cycle for one BEV replacing an ICEV.

Period (Flow method: Include entire lifetime CO2 emissions of the product in its first sales year)

Lifetime travel distance.

- Average annual travel distance respectively in Japan, U.S. and Europe*33 x Vehicle life (10 years)

- CO2 emissions reduction effect continues during that period.

*33 Assuming that vehicles equipped with cylindrical lithium-ion batteries are sold on the global market, we used the average for the three regions.

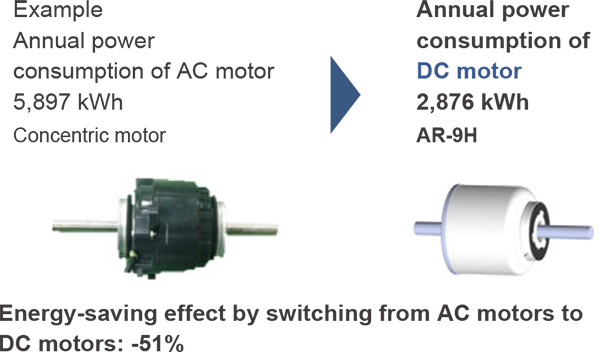

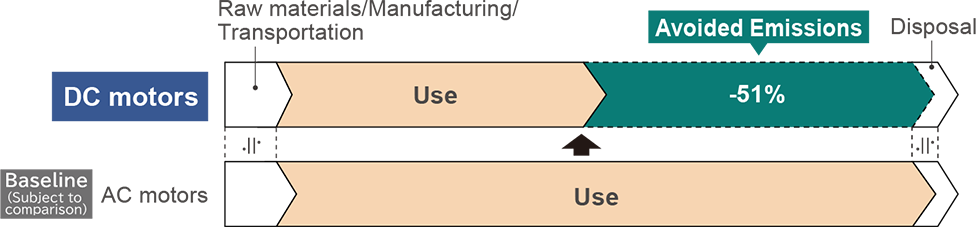

DC Fan Motor for Energy Saving in Air Conditioning Systems

Main product life stages subject to avoided CO2 emissions

Sales regions: Japan, Europe, North America, China, India, Southeast Asia, Central and South America, Middle East and Africa

Overview

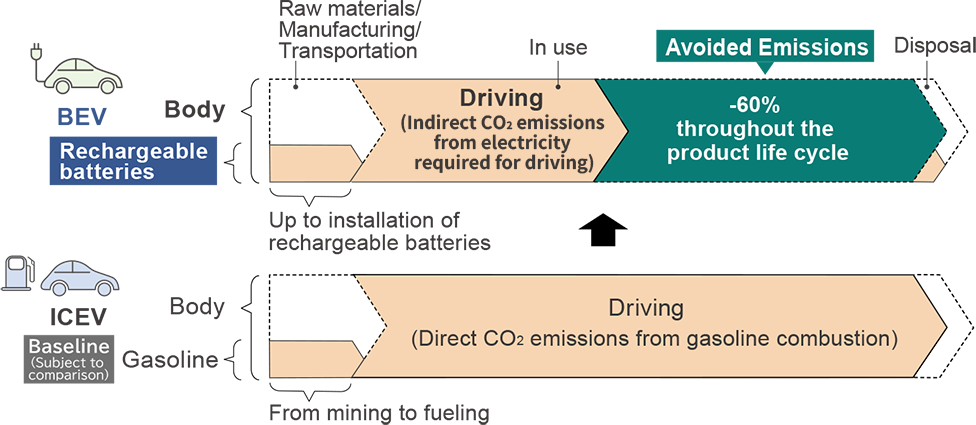

Improving energy efficiency in common electric appliances reduces the burden on the local electric grid where the appliances are used, and lowers concern for renewable energy supply sufficiency. In other words, it accelerates the shift to carbon neutrality driven by demand side of energy. Replacing old products with new ones with better energy efficiency reduces CO2 emissions from both customers and energy suppliers. Motors in air conditioning systems are a major component in terms of overall system performance. Although the motor's power consumption is less than 10% that of the entire system, the motor's energy-saving performance directly reduces CO2 emissions from the customer who uses the air conditioning system over the entire product lifetime.

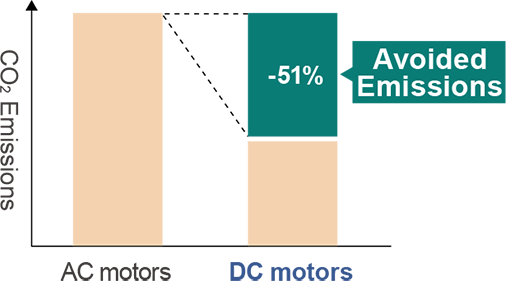

Avoided CO2 emissions mechanism

Compared to an Alternating Current (AC) motor, the speed of a Direct Current (DC) motor can varies according to the applied voltage or current, thereby reducing energy consumption losses.

[Example] Comparison of CO2 emissions converted from lifetime power consumption between AC motors and DC motors

Calculation formula of avoided emissions

![[Amount of activities] (Number of units) The number of units sold per year * AC motor penetration rate per sales region * (Annual power consumption of AC motors (kWh) - Annual power consumption of DC motors (kWh)) * CO2 emission factor for electricity per sales region (kg CO2 /kWh) * Period(9 years) | Annual avoided emissions from energy-saving effect by one replaced product | CO2 Emission Factor (IEA2021) Unit: kg/kWh /Region (Factor)Japan (0.487) Europe (0.277) North America (0.383) China (0.623) India (0.723) Southeast Asia (0.386) Central and South America (0.252) Middle East and Africa (0.616)](/content/dam/holdings/global/en/corporate/sustainability/environment/vision/eco-vision_c_04.png)

Baseline (Subject to comparison)

The baseline is the volume of CO2 emissions equivalent to the lifetime power consumption of an AC motor, that is an equivalent model to the DC motor, in the case that is used in the same conditions in each motor sales region. The areas where the air conditioning systems are used are assumed to be the same as the motor sales region.

Coverage of quantification (Concept and rationalization)

When the motor is in use. The subject of calculation is the motor's CFP*, and the CFP when in use is an average of 80 to 90% of the air conditioning system's total CFP. The CFPs of two systems, one with an AC motor (baseline) and the other with a DC motor, are the same when not in use.

Therefore, we determined that we need only study the difference in the CFP between the baseline and the DC systems in use, ignoring the impact from any differences in the CFP at other times.

Amount of activities (Unit)

The number of annual sales depending on the status (penetration rate, etc.) per sales region for DC motor.

Avoided CO2 emissions per unit of amount of activities (Latest basic unit)

Difference between CO2 emissions converted from lifetime power consumption*34 between those from the products before and after replacement in each sales region.

*34 Rated power in design x annual time in use x efficiency

Period (Flow method: Include entire lifetime CO2 emissions of the product in its first sales year)

- 9 years. (Product life defined by Panasonic)

CO2 emissions reduction effect continues during that period. - We deemed that 9 years for holding spare parts is a conservative estimate as the life of home appliances can be extended with appropriate use and maintenance.

- With the extended product life, further CO2 emissions reduction effects are also expected because of efficient utilization of resources.

Avoided CO2 emissions in fiscal 2025 : 8.16 million tons

*CFP (Carbon Footprint of Products): CO2 emissions converted from GHG emissions throughout the entire product life cycle—from raw material procurement to disposal and recycling of a product and service (per one unit).

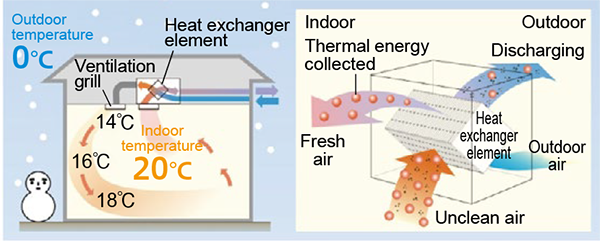

Heat Exchange System

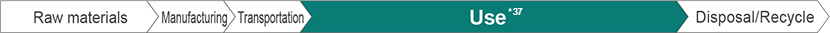

Main product life stages subject to avoided CO2 emissions

*35 Reduction in CO2 emissions from reducing air conditioning heat loss from room spaces during the period of use of the products.

Sales regions: Japan, China, North America, and Europe

Overview

To achieve decarbonization in the consumer and business sectors, it is important to reduce environmental impact from air conditioning at living spaces in houses and offices. Energy Recovery Ventilators (ERV) System reduces heat loss from the interior of buildings and provide comfort maintaining appropriate air quality at the same time. ERV System exchanges heat of indoor and outdoor with a heat exchange element during ventilation and either heat or cool the air before being taken into the building, which reduces air conditioning load. Moreover, the system is equipped with air purifier that is a high performance system. Therefore, ERV System is used in wide areas in residential, commercial, and office buildings, where high air tightness is required including Japan, the U.S., Europe, and China.

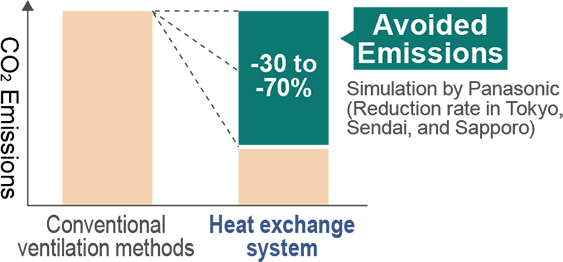

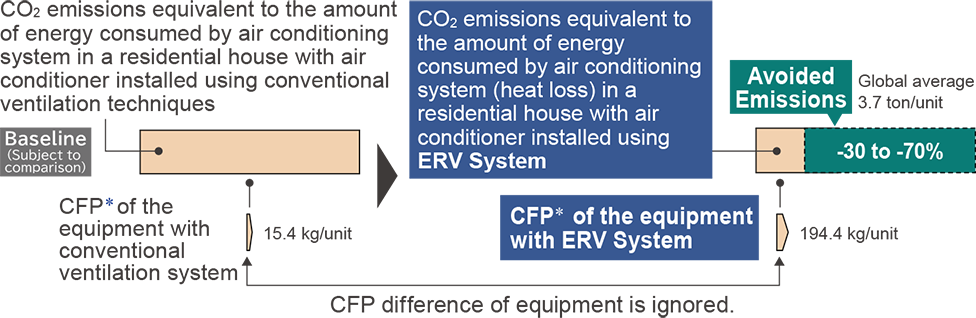

Avoided CO2 emissions mechanism

CO2 emissions converted from the reduced amount of power or fuel consumption by adopting this ERV System in room spaces under the same conditions compared to those from average ventilation method for ventilation in the market.

How ERV System works (winter)

* Efficiency varies according to model.

CO2 emissions converted from energy consumption with adjusted heat loss from ventilation

Calculation formula of avoided emissions

![[ Amount of activities] Annual system installation volume (The number of heat exchange systems) * (Annual energy consumed by air conditioning in a residential house with conventional ventilation methods (volume of thermal loss) (kWh or liters) * CO2 emission factors by electricity or fuel type in each sales region (kg CO2 /kWh or liters) - Annual energy consumed by air conditioning in a residential house with a ERV System (volume of thermal loss) (kWh or liters) * CO2 emission factors by electricity or fuel type in each sales region (kg CO2 /kWh or liters)) * Period (Ten years) | Annual avoided emissions by installed one ERV System | /CO2 emission factor for electricity: 0.487 kg/kWh in Japan, 0.623 kg/kWh in China, 0.383 kg/kWh in North America, and 0.277 kg/kWh in Europe (Source: IEA 2021) CO2 emission factor for kerosene: 2.49 kg/liter Data from the Ministry of the Environment used globally.](/content/dam/holdings/global/en/corporate/sustainability/environment/vision/eco-vision_d_03.png)

Baseline (Subject to comparison)

CO2 emissions converted from power and fuel consumption per each sales region from the use of air conditioners in a residential house where the current average ventilation systems in the market is installed.

Coverage of quantification (Concept and rationalization)

Difference in the heating and cooling load of the house before and after installation of the heat exchange system (this product). The CFP* for this product is greater than for a conventional ventilation system; however, the equivalent CO2 emissions from the difference in the heating and cooling load in a residential house before and after installation of a heat exchange air system is small (our calculation). Therefore, we decided that the effect can be ignored.

Amount of activities (Unit)

The number of annual sales of heat exchange units, which is the core function of the system.

Avoided CO2 emissions per unit of amount of activities (Latest basic unit)

We calculated the average air conditioning load from an average ventilation method in the living space of a residential house in Japan using our simulation for each sales region.

We then determined the difference in the volume of energy consumed by system operation for air conditioning in living spaces between the conventional ventilation method and the energy exchanged method, and multiplied it by the CO2 emission factors for electricity or fuel*36 by each sales region.

*36 Kerosene was used as the fuel.

Period (Flow method: Include entire lifetime CO2 emissions of the product in its first sales year in one time.)

- Designed lifetime of ERV System (10 years)

- CO2 emissions reduction effect continues during the period.

*CFP (Carbon Footprint of Products): CO2 emissions converted from GHG emissions throughout the entire product life cycle—from raw material procurement to disposal and recycling of a product and service (per one unit).

Distributed Storage Battery System for Data Centers

Main product life stages subject to avoided CO2 emissions

*37 Reduction of CO2 emissions in data centers during the period of use of the products

Sales regions: North America

Overview

Along with the rapid evolution of generative AI, power consumption in data centers (DCs) is also increasing due to the growing complexity of and advancements being made in data processing. In such DCs, more and more storage batteries are being used. One type of power source arrangements in DCs is a common centralized power supply arrangement in which lead-acid and LFP-type batteries are placed in a room managed separately from the server room. The other is a distributed power source arrangement, where high-power and compact lithium-ion batteries are installed within each server rack. Compared to the centralized arrangement, the distributed arrangement is more efficient as a power supply to the servers. This is because the distributed arrangement is space saving, and allows finer electricity and source management, optimizing energy usage.

[Reference] DC storage battery business (Japanese)

Avoided CO2 emissions mechanism

The distributed arrangement requires less number of voltage conversions from the supply to the server, compared with the centralized arrangement. This improves power efficiency in DCs.

CO2 emissions from lifetime power supply by DCs

Calculation formula of avoided emissions

![[ Amount of activities] (Number of units) The number of power storage battery system for DCs sold per year * (Annual power consumption by centralized power source arrangement (MWh) - Annual power consumption by distributed power source arrangement (MWh)) * CO2 emission factor for electricity in North America (0.325 ton- CO2 /MWh) * Period (Designed product life) (0.325 ton- CO2 /MWh) | Annual avoided emissions from energy loss reduction by distributed power source arrangement |](/content/dam/holdings/global/en/corporate/sustainability/environment/vision/eco-vision_h_03.png)

Baseline (Subject to comparison)

CO2 emissions converted from lifetime power consumption by using distributed power source arrangement.

Coverage of quantification (Concept and rationalization)

DC's CFP* was deemed to be the same in the two arrangements, except in use. The calculation subject is the difference in CO2 emissions from the storage batteries required to run the DCs in the two arrangements.

[Reference] LCAs of lithium-ion batteries and lead storage batteries

Amount of activitie (Unit)

The annual sales of distributed storage battery systems containing lithium-ion batteries installed in DCs.

Avoided CO2 emissions per unit of amount of activities (Latest basic unit)

Multiply the difference in the amount of electricity supplied from the centralized power source and the distributed DCs power source by the CO2 emission factor.

Period (Flow method: Include entire lifetime CO2 emissions of the product in its first sales of the year)

- Designed product life.

- CO2 emissions reduction effect continues during the period.

*CFP (Carbon Footprint of Products): CO2 emissions converted from GHG emissions throughout the entire product life cycle—from raw material procurement to disposal and recycling of a product and service (per one unit).

Vacuum Insulated Glass, Glavenir

Main product life stages subject to avoided CO2 emissions

*39 Reduction in CO2 emissions from reducing loads in cooling or heating in the building during the period of use of the products.

Sales regions: Japan

Overview

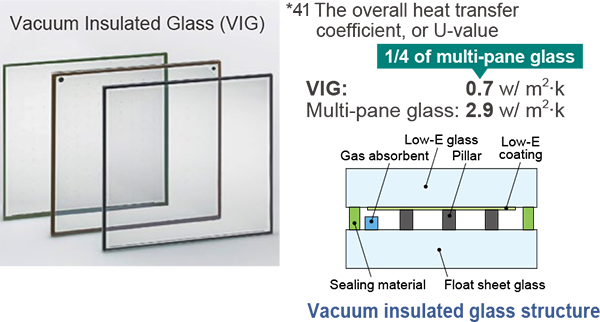

One effective means of achieving decarbonization in the consumer and business sectors is through reducing the air conditioning load in spaces in residential houses and offices by maintaining stable room temperatures through improved building insulation. In particular, heat inflow and outflow from windows account for 73% (inflow) of heat during summer cooling and 58% (outflow) during winter heating*40.

Our Vacuum Insulated Glass (VIG) achieves high insulation while at the same time maintaining its thinness, that can be adopted for existing openings (windows) in buildings as they are. Therefore, VIG has a potential to offer high applicability to a wide range of room spaces in different types of both new and older buildings.

Avoided CO2 emissions mechanism

Vacuum insulated glass (VIG) shows significantly higher thermal insulation compared to those of single-pane glass and Low-E multi-pane glass.*41 CO2 emissions converted from the reduced amount of power of electricity required for operation of air conditioning equipment by installation of the VIG for glass material of buildings.

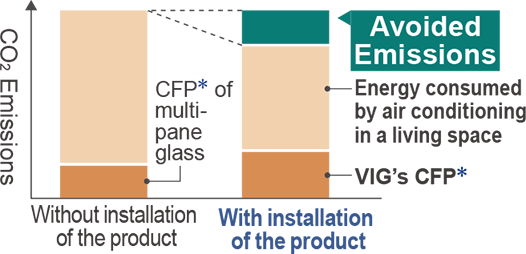

Comparison of CO2 emissions from energy consumed by air conditioning in a residential house with/without VIG windows, taking account of the glass’s CFP.*

Calculation formula of avoided emissions

![[ Amount of activities] (m2) Amount of VIG sold per year | *42 Calculated based on our simulation using data from the Architectural Institute of Japan. *43 Calculated based on data from the Flat Glass Manufacturers Association of Japan, by Panasonic. | * (Power consumed by air conditioning in a residential house with single-pane or Low-E multi-pane glass*4 per year (kWh/ m2) - Power consumed by air conditioning in a residential house with VIG*42 per year (kWh/ m2)) * CO2 emission factor for electricity (kg CO2 /kWh) * Period (Designed lifetime) - (VIG’s CFP*,*43 (kg CO2 / m2) - Single-pane or Low-E multi-pane glass’s CFP*,*43 (kg CO2 kWh/ m2)) | Annual avoided emissions achieved by installation of 1 m2 of VIG | /CO2 emission factor for electricity Japan 0.487 kg/kWh (Source: IEA 2021)](/content/dam/holdings/global/en/corporate/sustainability/environment/vision/eco-vision_f_03.png)

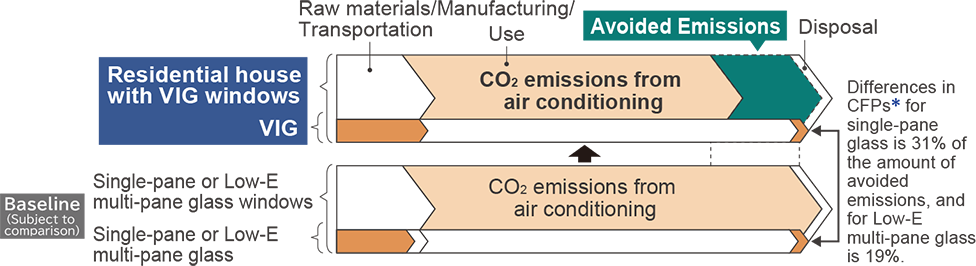

Baseline (Subject to comparison)

CO2 emissions converted from electricity consumed by air conditioning operations in the entire space of a respective residential house in Japan.

For the installation of VIG, it is set that VIG replaces single-pane glass when reforming a house, and replaces Low-E multi-pane glass when building a new house.

Coverage of quantification (Concept and rationalization)

- In use: CO2 emissions derived from electricity consumed by air conditioning in an entire residential house.

- Glass’s CFP*: VIG’s CFP* is greater than that of single-pane or Low-E multi-pane glass, however, there are no CO2 emission from the glass in use.

The difference between the CFPs* from VIG and single-pane glass is 31% of avoided emissions, and the difference between VIG and Low-E multi-pane glass is 19% of avoided emissions. These differences were subtracted from the avoided emissions, instead of ignoring them.

Amount of activities (m2)

Amount of VIG sold per year.

Avoided CO2 emissions per unit of amount of activities (Latest basic unit)

- In use: Differences in electricity consumed by air conditioning in residential houses per different type of glass.

Note: Annual power consumption was calculated by us, using a simulation of a two-story wooden house with a floor space of 120 m2 based on standard weather data from the Architectural Institute of Japan using air conditioning heat load computing software. - CFPs* for glass: Calculated by ourselves, per type of glass based on data from the Flat Glass Manufacturers Association of Japan.

Period (Flow method: Include entire lifetime CO2 emissions of the product in its first sales year in one time)

- Designed lifetime of VIG.

- CO2 emissions reduction effect continues during the period.

- We believe that the CO2 emissions effects are estimated from a conservative view because the life of a Japanese residential house is generally deemed much longer.

*CFP (Carbon Footprint of Products): CO2 emissions converted from GHG emissions throughout the entire product life cycle—from raw material procurement to disposal and recycling of a product and service (per one unit).

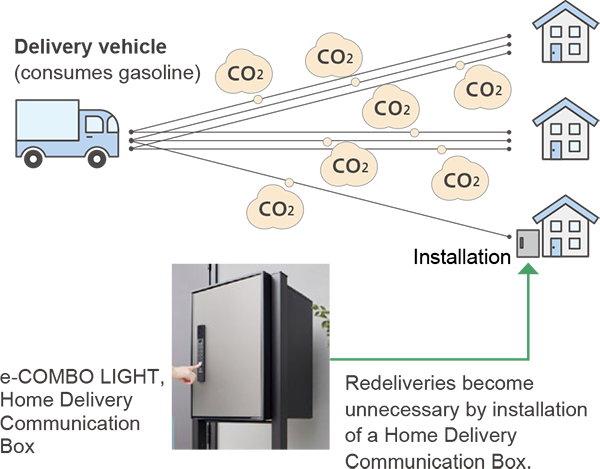

Home Delivery Communication Box, e-COMBO

Main product life stages subject to avoided CO2 emissions

*44 Reduction of CO2 emissions by home delivery services during the period of use of the products

Sales regions: Japan

Overview

In the household business sector in Japan, because of increase in e-commerce trading and increase in the time when none is at home along with changes in lifestyle, load for distribution on couriers is on increase as the number of redelivery of goods increases. Installation of a Home Delivery Communication Box at home can avoid redelivery of goods, lowers the burden for the parcel receivers, and decreases the working hours of couriers workers. At the same time, it reduces CO2 emissions from energy consumption such as fuel for deliveries, which contributes to reduction of load in local distribution networks and decarbonization.

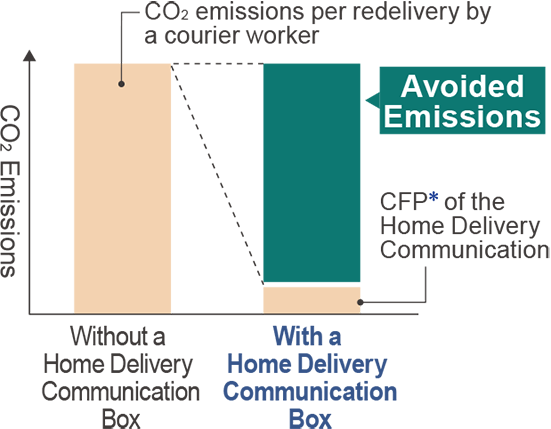

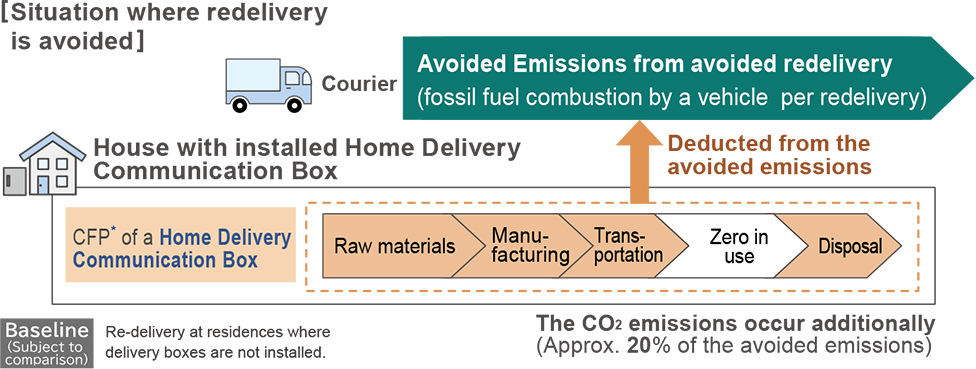

Avoided CO2 emissions mechanism

Reduction of CO2 emissions from energy consumption (combustion of fossil fuel such as gasoline) required for courier workers to redeliver goods, by avoiding redeliveries.

CO2 emissions with and without one Home Delivery Communication Box

(CO2 emissions from a vehicle on redelivery by the courier worker and CFP* of the Home Delivery Communication Box)

Calculation formula of avoided emissions

![[Amount of activities] (Units) The number of Home Delivery Communication Boxes sold per year. * (Avoided emissions per vehicle per redelivery (0.46 kg/redelivery) | * Verified data by Ministry of Land, Infrastructure, Transport and Tourism (MLIT) | * Annual number of redeliveries | * Verified data by Panasonic | * Period(Designed lifetime of the product) - CFP* of a Home Delivery Communication Box | * Estimated by Panasonic |](/content/dam/holdings/global/en/corporate/sustainability/environment/vision/eco-vision_g_03.png)

Baseline (Subject to comparison)

CO2 emissions converted from the average energy consumption from redelivery of goods by courier workers, in the case that the receivers of the goods did not receive the goods at the first delivery as they were not at home where a Home Delivery Communication Box is not installed.

Coverage of quantification (Concept and rationalization)

When the box is in use (avoided emissions from avoided redelivery by installation of a Home Delivery Communication Box). Although the box emits no CO2 when it is in use, the CFP* of the box itself is 20% of entire avoided emissions (by our estimation). However, this was not included in the avoided emissions as it is an additional effect.

Amount of activities (Unit)

The number of Home Delivery Communication Boxes sold per year.

Avoided CO2 emissions per unit of amount of activities (Latest basic unit)

- Avoided emissions per redelivery: 0.46 kg (Source: Verified data by MLIT)

- The number of redeliveries: Verified data by Panasonic

Period (Flow method: Include entire lifetime CO2 emissions of the product in its first sales year)

- Designed lifetime of a Home Delivery Communication Box.

- CO2 emissions reduction effect continues during the period.

- We deemed that the design life of the Home Delivery Communication Box is a conservative estimate for CO2 emission effects as the box’s life can be extended further with appropriate use and maintenance.

*CFP (Carbon Footprint of Products): CO2 emissions converted from GHG emissions throughout the entire product life cycle—from raw material procurement to disposal and recycling of a product and service (per one unit).

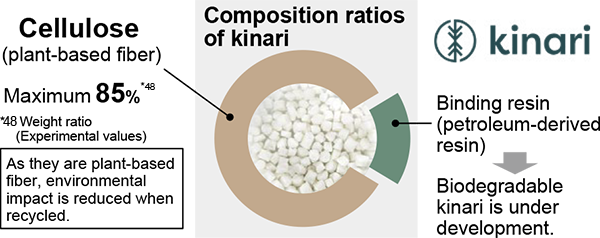

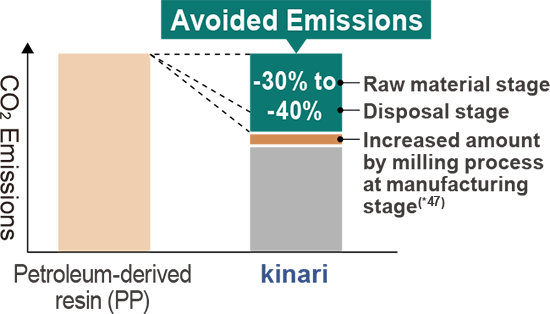

High Concentration Cellulose Fiber Molding Material, kinari New

Main product life stages subject to avoided CO2 emissions

Sales regions: Japan

Overview

The production volume of petroleum-derived plastic (hereafter, resin) is expected to increase to 610 million tons by 2030 from 450 million tons in 2020*45. However, its recycling rate is limited to 9%*46, posing a challenge in terms of waste recycling and carbon neutrality. For 20 more years in Japan, Panasonic has been recycling the home appliances that we produced, promoting recycling-oriented manufacturing. However, the single resin (high purity and quality) that can be manually collected from waste home appliances is limited to 20% of the entire resin used in a product. Also, much of the mixed resin (low purity and medium quality) collected by machine shredding cannot be used for new products.

One of the solutions to this issue is replacing the resin components with bio resin, which is made from corn and other materials. Nonetheless other problems still remain, such as the impact on food production and occasional issues with functionality. Our high concentration cellulose fiber molding material, kinari, is made from plant-based materials such as forest thinning timber and industrial wastes, and has a competitive advantage due to its better density, strength, and price compared to other fiber materials. Kinari can contain up to 85% cellulose fiber, yet it is lighter than petroleum-derived resin. It can also be shaped by existing molding machines. Increasing use of kinari should contribute to building a circular economy and achieving carbon neutrality.

*45 Bioplastics 2020-2025 (IDTechEx Report)

*46 Production, use, and fate of all plastics ever made | Science Advances

Avoided CO2 emissions mechanism

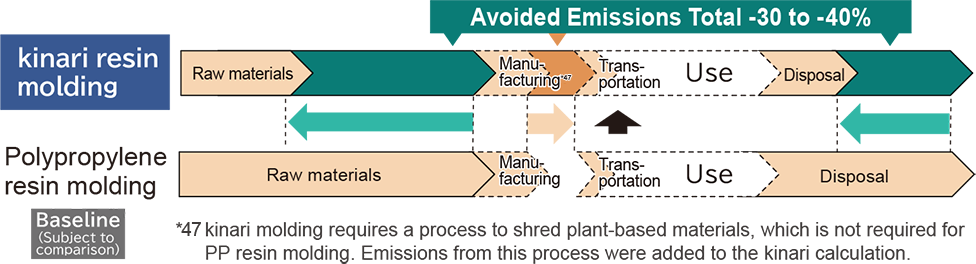

Compared to a standard petroleum-derived resin molding, a kinari molding can offer a CO2 emissions reduction effect in the phases of material procurement and molding disposal. Although kinari requires the shredding of plant materials, even taking account of the impact from such shredding, kinari molding’s CO2 emissions across its life cycle are smaller than those from petroleum-derived molding.

CO2 emissions of petroleum-derived resin and kinari

(CFP* comparison between molding product)

Calculation formula of avoided emissions

![[Amount of activities] The number of kinari packages sold per year (1 pack: 25 kg) * (CFP* for standard polypropylene resin molding (Calculated under the SuMPO EPD program) - CFP* for kinari resin molding (Including the amount of carbon stock of kinari at disposal.)) * 1 (once)Reduction effect takes place once in a molding’s life cycle.](/content/dam/holdings/global/en/corporate/sustainability/environment/vision/eco-vision_i_03.png)

Baseline (Subject to comparison)

CFP* for standard polypropylene resin molding.

Coverage of quantification (Concept and rationalization)

The difference in CO2 emissions between kinari and the baseline must be determined covering the phases of material procurement, production, transportation, and disposal. However, we did not include the phases of production, transportation, and usage for quantification. This was because the difference in emissions during use was zero, and the production and transportation processes are identical for both kinari and the baseline.

Amount of activities (Unit)

The number of kinari packages sold per year (1 pack: 25 kg)

Avoided CO2 emissions per unit of amount of activity (Latest basic unit)

The difference between CO2 emissions*49 across the life cycle of a standard PP resin molding and that of a kinari molding.

*49 Figures calculated by us based on the SuMPO EPD program.

The calculations took account of the amount of carbon stock of kinari at disposal.

Period: Once

Reduction effect takes place once in a molding’s life cycle.

Avoided CO2 emissions in fiscal 2025 : 11 tons

Petroleum-based plastic reduction in fiscal 2025 : 2.4 tons

*CFP (Carbon Footprint of Products): CO2 emissions converted from GHG emissions throughout the entire product life cycle—from raw material procurement to disposal and recycling of a product and service (per one unit).

Activities to raise awareness of and valorize Avoided CO2 Emissions

Under the current GHG Protocol, it is possible to evaluate CO2 emissions from our business activities; however, it does not take into account the contribution to society through our business (opportunities, i.e., business chance) as of now. On the other hand, although there is a concept of the avoided emissions, in reality awareness of the avoided emissions is still low in society and no uniformed standard for the avoided emissions has been established. Therefore, it is a must to establish a structure to facilitate and encourage respective corporations efforts to decarbonation (technical development and innovation), as well as to contributes to the acceleration of the realization of a carbon-neutral society by preparing environment where respective corporation's contribution to decarbonization is properly evaluated.

Our environmental vision, Panasonic GREEN IMPACT (PGI), sets out the CO2 emissions reduction targets not only for our company but also for society as a whole. It is important to spread significance of the avoided emissions as 'a standard measurement' to evaluate the corporation's contribution to decarbonization efforts and expand awareness of the avoided emissions, together with stakeholders such as corporations and financial institutions who share the same ambitions. Therefore, we are currently implementing the following activities regarding the avoided emissions towards its global standardization, and raising and spreading its awareness

Standardization Activities

International Electrotechnical Commission (IEC)

In September 2020, activities of standardization of a new IEC standard proposed by Japan's proposal started. Specifically, the activities are calculation of the avoided emissions from new technologies, such as AI, IoT, and a digital twin; provision of requirements for the calculation methods; establishment of requirements for communications and information disclosure, and preparation of an international standard IEC63372 titled "Quantification and communication of GHG emissions and emission reductions/avoided emissions from electric and electronic products and systems - Principles, methodologies, requirements, and guidance." In June 2025, the Final Draft International Standard was completed for IEC TC111 (Environmental standardization for electrical and electronic products and systems) and it is scheduled to be published as an IEC standard by the end of 2025, if progress continues smoothly. We are participating in this activity as a IEC technical committee member to promote standardization, such as through our proposal for calculating our avoided CO2 emissions.

World Business Council for Sustainable Development (WBCSD)

WBCSD is a global organization of approximately 200 leading companies committed to sustainable development, working together to contribute to transformation to sustainable society.

Endorsing the principles of WBCSD, Panasonic Holdings Corporation (PHD) joined WBCSD in 2022 to accelerate the Panasonic Group's PGI activities. Since publication of the Guidance on Avoided Emissions in 2023, WBCSD is reviewing its updated version and developing guidance for each industrial sector. We have been involved actively in their development, working in close cooperation with the organization and its member companies to conduct standardization and disseminate information on avoided CO2 emissions.

GX League*50

To establish a system whereby the opportunities for Japan's corporations contributions to climate change, such as by reducing emissions from the products and services they provide to the markets, are properly evaluated, Panasonic has participated as a leading member of the GX Business Working Group since its inception, in the area of rulemaking for market creation that is one of the GX League activities.

To expand awareness of the avoided emissions that is one of the disclosure items used in the Panasonic Group's long-term environmental vision in evaluating opportunities related to climate change, we jointly published with other GX league member company a collection of use examples by financial institutions in December 2023, and in May 2024 a virtual collection of recommended information disclosure by our operating companies, following to "the Basic Policy for disclosure and evaluation for opportunities related to climate change" published in fiscal 2023.

*50 GX stands for 'Green Transformation'. In February 2022, the Industrial Science and Technology Policy and Environment Bureau of the Ministry of Economy, Trade and Industry (METI) announced the GX League Basic Concept. GX League was launched as an apparatus where the company groups who are proactively working for GX with players in industry, government, academia and financial institutions challenge towards GX as a whole to discuss transformation of a whole society, economic and environmental system and implement activities to create new markets.

Appeal of the avoided emissions at international events

As a result of our fiscal 2023 activities for raising awareness and dissemination of the avoided emissions at international events, the activities were clearly stated in the 2023 G7 outcome documents. We have continued working to raise awareness and valorize the avoided emissions in fiscal 2025.

COP29 (The 2024 Conference of the Parties of the United Nations Framework Convention on Climate Change (UNFCCC))

In November 2024, the Group gave a presentation on the importance of standardizing avoided CO2 emissions and the progress achieved to date at a seminar titled "Moving forward with standardization of avoided CO2 emissions in the industrial and financial sectors," held at the Japan Pavilion. In addition, we reported that we are involved in standardization at the International Electrotechnical Commission (IEC) for IEC 63372 and that we are also working in coordination with ISO and WBCSD. We expect that standardization of avoided CO2 emissions will lead to appropriate assessment of businesses that contribute to decarbonization by governments and financial institutions, and that the findings will be used in investment decisionmaking and in granting incentives. Additionally, we emphasized that it is important for the entire industrial sector to achieve the climate targets adopted at COP21, not only the electrical and electronic industries.

CES2025

In the opening keynote at CES 2025 held in January 2025, we announced that resolving issues in the global environment is our top priority in building an ideal society that offers material and spiritual affluence and stressed the need to preserve a sound and healthy global environment for future generations. We stressed the importance of avoided CO2 emissions by working in cooperation with WBCSD to speed up action on the development of and innovations for decarbonization technology across society as a whole.