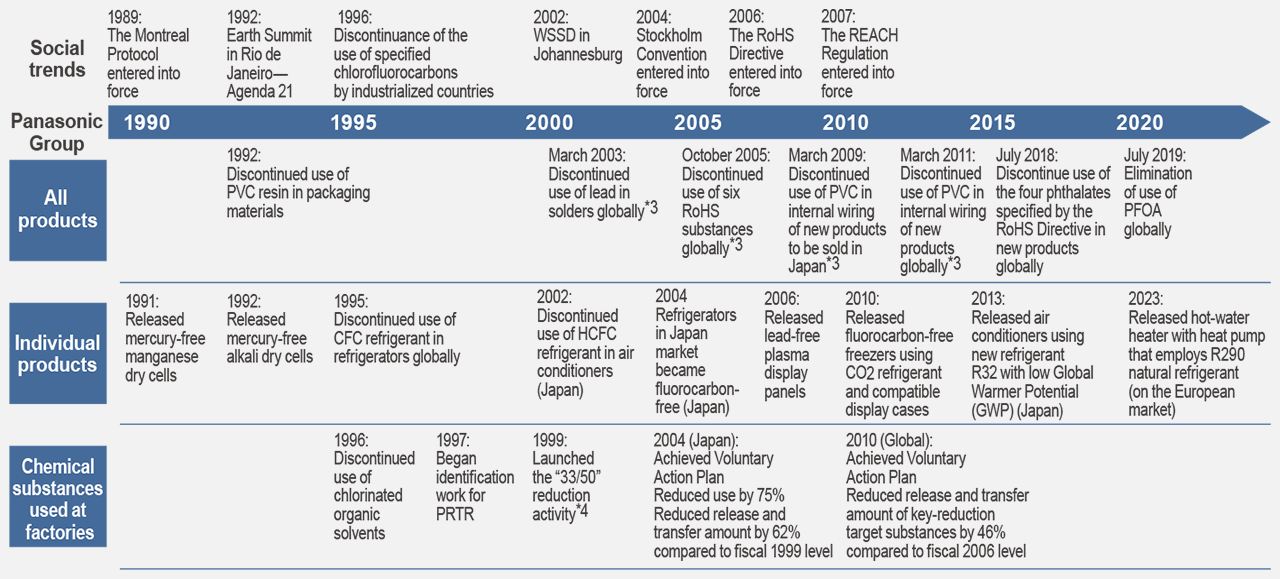

Approaches to Reducing the Environmental Impact of Chemical Substances

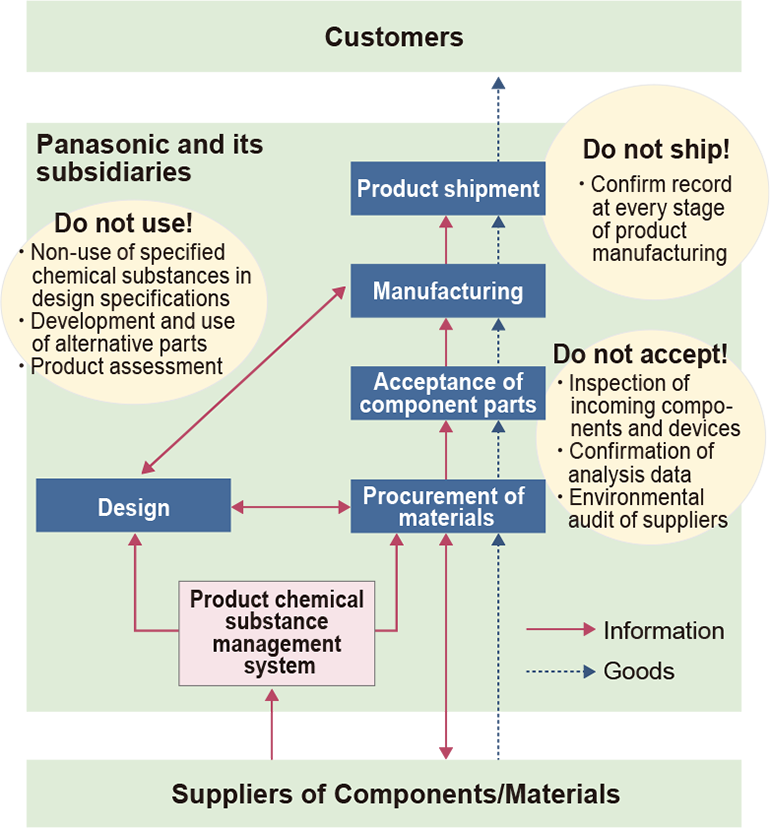

In order to prevent contents of hazardous substances prohibited under the EU RoHS Directive*1, and the like in Panasonic Group's products, it is important not only to pay attention to the contents at the stage of product design, but also to ensure that specified substances are not contained in products to purchase.Therefore, the Panasonic Group has rolled out the "Do not accept! Do not use! Do not ship!" campaign throughout the each production process from designing to shipment inspection in production activities at business sites across the world since October 2005. Specifically, as for the stage of inspection for incoming components, we have established a mechanism to check and analyze whether specified chemical substances are included by introducing an analyzer.

In addition, we have supported to establish a Product Chemical Substances Management Structure, by periodically conducting environmental audits for suppliers of components/materials which may have high risks of containing specified chemical substances.

Specified chemical substance management system

Specified Chemical Substance Management System

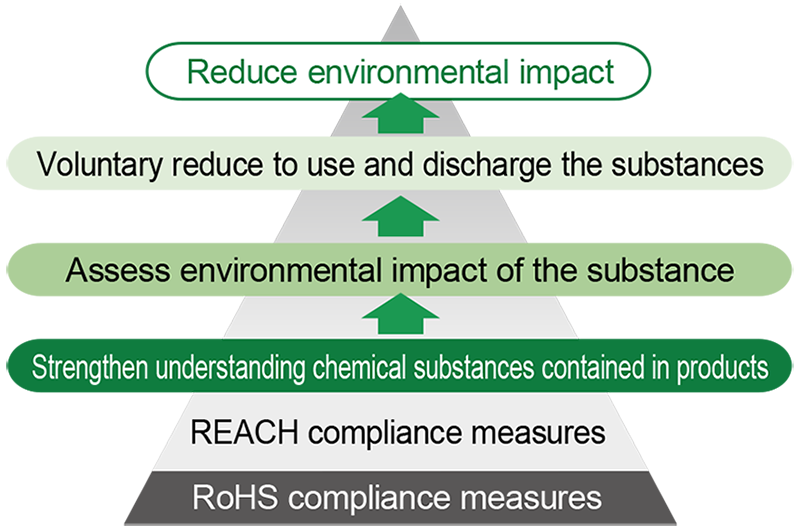

Meanwhile, as represented by the enforcement of the REACH regulation*2 in the European Union, the world implemented measures toward the goals agreed at the World Summit on Sustainable Development (WSSD) held in 2002, which is to produce and use all chemical substances in a manner that minimizes their impact on human health and the environment by 2020. Although the subsequent discussion was delayed as the conference could not be held due to the COVID-19 pandemic, in the fifth International Conference on Chemicals Management (ICCM5) held in in Germany September 2023, a new international framework that succeeds the activities up to 2020 was discussed; concerning appropriate chemical management, a new international framework for voluntary and diverse actors to be involved was formulated. Panasonic Group has been supporting the precautionary approach proposed in the Rio Declaration at the Earth Summit in 1992, and has continued its efforts for appropriate chemical management on a global scale even after 2020 that is the final target year of the WSSD framework. Furthermore, in order to continue implementation of product manufacturing in line with our basic policy of reducing the use of chemical substances that might adversely affect human health and the environment throughout their lifecycles, we determined chemical management as one of our continuing issues, and we are constantly working to reduce environmental loads of the chemicals used in our business activities and products. As for concrete activities, we have worked to comply with relevant regulations such as EU RoHS as a matter of course. In addition, we have worked to reduce adverse environmental impact originated by our group products as much as possible by (1) trying to understand hazardous substances contained in our products, (2) evaluating these substances on their environmental impact, and (3) voluntarily reducing or discontinuing their use in case of any environmental risks of the substances. We will continue to implement appropriate chemical management of such chemical substances while monitoring global environmental trends.

*1 Directive on the Restriction of the use of certain Hazardous Substances in electrical and electronic equipment The RoHS Directive currently restricts use of the following ten substances beyond the specified concentrations shown in parentheses:

lead (0.1%), cadmium (0.01%), mercury (0.1%), hexavalent chromium (0.1%), polybrominated biphenyls and polybrominated diphenyl ethers (0.1%), four phthalates (DEHP, BBP, DBP, and DIBP) (0.1%).

However, the RoHS Directive allows exemptions from its restrictions for a limited time if substitution is technologically or scientifically impossible. Exemptions stipulate specific restrictions in details on the use, concentration limit, and time frame for each substance.

< Exemption examples >

Lead: Glass, ceramics, and high-temperature soldering used in electronic components.

Mercury: Cold-cathode tubes used in LCD backlighting and fluorescent lighting.

Note that vehicles and batteries are not subject to the restrictions under the EU RoHS Directive.

The EU End of Life Vehicles Directive details restrictions for vehicles and the EU Battery Directive (amended and promulgated as EU Battery Regulation in July 2023) details restrictions for batteries.

*2 Regulations on the registration, evaluation, authorization, and restriction of chemical substances.

Process to Reduce the Environmental Impact of Chemical Substances

In order to definitely implement such activities described above, we issued our Chemical Substances Management Rank Guidelines that specifies prohibited chemical substances and management substances concerning products and activities at factories. We request to take actions to the chemical substances in accordance with the guidelines, not only to Companies in the Panasonic Group, but also to our suppliers. In fiscal 2013, we added Level 3 of prohibited substances to the category of the Chemical Substances Management Rank Guidelines (For Products).

We not only consider nonuse of the prohibited substances, or the substances to be prohibited under laws and regulations, but we also consider prohibiting concerned substances that may adversely affect human health and the environment in the future. Further, we are striving to comply with relevant laws and regulations, and mitigate effects of toxic substances on human health and the environment by increasing the number of globally prohibited substances (Level 1) beyond boundaries of countries subject to the applicable laws and regulations from 21 substances/groups in fiscal 2015 to 30 substances/groups in fiscal 2024.

The Chemical Substances Management Rank Guidelines (For Products) and relevant documents, which includes clear description of prohibited substances and management substances, is available in PDF file for your downloaded from the following website. (Green Procurement).

Chemical Substances Management Rank Guidelines (For Products)

| Rank | Definition | |

|---|---|---|

| Prohibit | Level 1 | (1) A substance contained in products that is prohibited by existing laws and regulations; or a substance where the upper limit of concentration is specified. (2) A substance that will be prohibited in products by laws and regulations or where the upper limit of concentration will be specified within one year after the revision date of this Guidelines. Note that there is a case that a substance is specified as the Level 1 prohibited substance more than 1 year before the enforcement date, because of the enforcement dates of the law and the Rank Guidelines. |

| Level 2 | Substances other than those specified as Level 1 and to which either of the following criteria applies: (1) Substances to be prohibited in products after a certain period by a treaty, law, or regulation. (2) Substances that are prohibited in products by the Panasonic Group prior to the effective period specified by a treaty, law, or regulation. (3) Substances whose use is voluntarily restricted by the Panasonic Group. | |

| Level 3 | Any substance other than those specified as a Level 1 or Level 2 Prohibited Substance that is under review for prohibition by laws, regulations, etc., and the clarification of substitution-related issues as well as the timing for prohibition will be reviewed by the Panasonic Group in light of future legislation trends. | |

| Manage | Substances whose actual use in products needs to be understood and for which consideration needs to be given to human health, safety and hygiene, adequate treatment, etc. The intentional use of these substances is not restricted, but their use and contained concentration must be monitored. | |

| Rank | Definition | |

|---|---|---|

| Prohibit | Level 1 | (1) A substance contained in products that is prohibited by existing laws and regulations; or a substance where the upper limit of concentration is specified. (2) A substance that will be prohibited in products by laws and regulations or where the upper limit of concentration will be specified within one year after the revision date of this Guidelines. Note that there is a case that a substance is specified as the Level 1 prohibited substance more than 1 year before the enforcement date, because of the enforcement dates of the law and the Rank Guidelines. |

| Level 2 | Substances other than those specified as Level 1 and to which either of the following criteria applies: (1) Substances to be prohibited in products after a certain period by a treaty, law, or regulation. (2) Substances that are prohibited in products by the Panasonic Group prior to the effective period specified by a treaty, law, or regulation. (3) Substances whose use is voluntarily restricted by the Panasonic Group. | |

| Level 3 | Any substance other than those specified as a Level 1 or Level 2 Prohibited Substance that is under review for prohibition by laws, regulations, etc., and the clarification of substitution-related issues as well as the timing for prohibition will be reviewed by the Panasonic Group in light of future legislation trends. | |

| Manage | Substances whose actual use in products needs to be understood and for which consideration needs to be given to human health, safety and hygiene, adequate treatment, etc. The intentional use of these substances is not restricted, but their use and contained concentration must be monitored. | |

Note: the laws, regulations and the substances subject to the above table are chemical substances specified as Class I Specified Chemical Substances under the Act on the Evaluation of Chemical Substances and Regulation of Their Manufacture, etc. the EU RoHS Directive Annex XVII of the EU REACH Regulation, etc. For more details, see the chapter 6 "Specified Managed Substances" in the Chemical Substances Management Rank Guidelines (For Products).

As for the hazardous substances whose manufacturing is prohibited under the Japan's Industrial Safety and Health Act, they are managed in accordance with the Specified Managed Substances in the Chemical Substances Management Rank Guidelines (For Factories)

Chemical Substances Management Rank Guidelines (For Factories)

| Rank | Definition |

| Prohibit | Use of the following substances should be immediately discontinued: Carcinogens for humans Ozone depleting substances Substances whose use is prohibited by Panasonic Chemical substances designated as Class I Specified Chemical Substances by the Japanese Act on the Evaluation of Chemical Substances and Regulation of Their Manufacture, etc. Substances whose manufacture is prohibited by the Japanese Industrial Safety and Health Act Substances whose manufacture and use are prohibited by international treaties |

| Reduce | Substances whose use, release and transfer should be identified and reduced. Substances other than prohibited substances that might pose risks to human health and the environment. |

| Rank | Definition |

| Prohibit | Use of the following substances should be immediately discontinued: Carcinogens for humans Ozone depleting substances Substances whose use is prohibited by Panasonic Chemical substances designated as Class I Specified Chemical Substances by the Japanese Act on the Evaluation of Chemical Substances and Regulation of Their Manufacture, etc. Substances whose manufacture is prohibited by the Japanese Industrial Safety and Health Act Substances whose manufacture and use are prohibited by international treaties |

| Reduce | Substances whose use, release and transfer should be identified and reduced. Substances other than prohibited substances that might pose risks to human health and the environment. |

Note: Covered legislation include: PRTR Act (chemical substances), environmental criteria under the Basic Environment Act; the Industrial Safety and Health Act; and the Stockholm Convention. For more details, see the contents on The Aim of Establishing the Chemical Substances Management Rank Guidelines (For Factories) in the Chemical Substances Management Rank Guidelines (For Factories).

*3 Excluding applications where the quality such as safety cannot be ensured, or applications where the material is designated by laws and regulations.

*4 A reduction activity that promotes cutbacks in the use, release, and transfer of chemical substances by 33% in three years and by 50% in six years, compared to the fiscal 1999 level.

Management of Chemical Substances in Products

To minimize the environmental impact of chemical substances contained in products, we endeavor to identify chemical substances used in the components and materials of our products. In addition, for substances that are prohibited in products in major developed countries because of laws and regulations such as the European RoHS Directive, we manage the substances not to be used and/or contained in our products by designating them as prohibited substances except the substance for specific usage which is unavoidable to use its substitution. We will also conduct environmental impact assessments for the managed substances contained in our products. As for a substance whose impact on human health and/or the environment cannot be ignored, we plan to reduce or prohibit use of the substance.

Continuously updating information concerning chemical substance contents

The electrical and electric products The Panasonic Group manufactures and sells consist of various raw materials and components supplied through a long supply chain from material manufacturers to many component manufacturers.

To contribute to the achievement of the global targets set at the WSSD and the new framework adopted by ICCM5, it is important for us to disclose and communicate information on the chemical substances used in our products across the supply chain, for which we must promote cross-industrial initiatives to establish and disseminate an effective system.

The Panasonic Group is a member of the Joint Article Management Promotion consortium (JAMP). Approximately 500 major companies from various industries, such as chemical, component, and equipment manufacturers are also members of JAMP. We are proactively formulating, utilizing, and disseminating chemical substance management standards and systems through this organization.

The Panasonic Group has started up a product chemical substance management system in fiscal 2005. From July, 2009, our 10,000 suppliers of materials and components provided us the data on chemical substances contained in their products, using JAMP’s data transmission formats (JAMP_AIS and JAP_MSDSplus).

Meanwhile, in Japan alone, the workload of upstream suppliers increased, as a number of hazardous substance inspections were carried out throughout the supply chain using own company format. Having recognized the issues obtained from the inspections, "chemSHERPA" (a new scheme for information communication for chemical substances in products) was proposed in 2015. Because the format adopted for chemSHERPA complies with IEC62474, the international standard on material declaration (a declaration of specific information about composition of the materials and chemical substances in the product) for the electrical and electronic machinery industry and their products, Panasonic Group agreed to use chemSHERPA format; and in January 2018, started full-scale use of chemSHERPA as a data gathering format. With the supply chain expanding to a global scale, it is particularly important for overseas suppliers to deepen their understanding on the handling of hazardous chemical substances. Therefore, our Group carried out education programs for persons in charge of chemical substance management and suppliers at more than 100 of our business sites in ten countries including China and other Asian countries. At the same time, the Panasonic Group completed conversion from JAMP format to chemSHERPA by June 2018.

(The JAMP website was merged into chemSHERPA on March 15, 2019)

While the Japanese automotive industry has been using the JAMA/JAPIA sheet*5 to share information on chemicals used in products in the supply chain, IMDS*6 is actually the defacto standard material data system used by the international automotive industry. With the backdrop of the Japanese automotive industry now shifting to IMDS from JAMA/JAPIA sheets, in October 2020 the Panasonic Group undertook a full data migration to IMDS for use in our automotive business. We held seminars to more than 200 suppliers and completed a successful data migration. This means that the Panasonic Group can now obtain data for the materials in the components received from our suppliers through IMDS into our management system for the chemical substances in our products, and, at the same time, we can deliver product chemical data to our customers. The system thus makes for easier material data communications throughout the supply chain.

Companies that procure electronic components need to fully understand the information on the substances contained in the components at the point of selection or usage in order to comply with the EU RoHS Directives and REACH regulations. Particularly, as the REACH Substances of Very High Concern (SVHC) List is updated every six months, those companies expect their suppliers to speedily provide information on the latest substance to the Panasonic Group. In order for the companies adopting our group's electric components to speedily and effectively understand the information on chemical substance contents, the Panasonic Group has published a table of RoHS and REACH compliance status on our website since November 2012. The table covers our RoHS Directive compliance information and the substances designated in the RoHS / REACH Confirmation Report for all our major generic electronic components.

*5 The standard material data format in the Japan's automotive industry (standardized by the Japan Automobile Manufacturers Association and the Japan Auto Parts Industries Association).

*6 International Material Data System: Material data system for automotive industry that is globally used.

For products covered by the Act on the Promotion of Effective Utilization of Resources of Japan, the Panasonic Group does not manufacture, import, or sell products that contain specified chemical substances which exceeds the limited value in non-exempt parts. For more details, see Information on the Content of Specified Chemical Substances below.

In June 2015, the Act on Preventing Environmental Pollution of Mercury was enacted to implement measures agreed in the Minamata Convention on Mercury. The act requires manufacturers of products containing mercury to provide information such as labelling as manufacturers responsibility, so that such products are appropriately sorted and discharged when being disposed of. In order to communicate information concerning the mercury used in our products to customers, the Panasonic Group opened the webpage to provide our information based on the Act on the Preventing Environmental Pollution of Mercury, in May 2017.

Assessing the Impact of Chemical Substances

Scientifically identifying the impact on human health and the environment of products containing chemical substances is vital to the development of products with low environmental impact. We are engaging in activities designed to assess the levels to which customers are exposed to substances of very high concern (SVHC), as well as safety during product usage 2011, we have assessed effects of ceramic fibers used in certain models of commercial microwave ovens. As part of our efforts to comply with the EU REACH regulation which requires preparing information for the safe use of products containing a certain amount of SVHC, we have created and publicized the safety assessment document. The exposure was considered to be nominal with little concern for any effects on human health. Furthermore, usage of ceramic fibers in our products was discontinued in December 2010.

Other than described above, we continue to conduct a Product Safety Assessment as a part of our responses to the U.S. State of California's Proposition 65 that aims to protect the state's citizens from chemical substances. Specifically, we conducted an exposure assessment experiment on diisononyl phthalate (DINP) in 2016, and on a brominated flame retardant (TBBPA: Tetrabromobisphenol A) in 2017, then created an exposure assessment tool based on the experiment results. As a result of the assessment, we confirmed that our products do not adversely affect users of our group products, i.e., customers. We are utilizing the exposure assessment tool to confirm product safety and to respond to relevant regulations.

Reduction in Use and Discharge of Chemical Substances

Fluorocarbons (CFC) used as refrigerants and insulating materials for freezers and air conditioners have properties that are known to cause ozone layer depletion and global warming.

The Panasonic Group has developed a refrigerant based on CO2 that has an extremely low effect on ozone depletion and global warming, and has been selling a home water heater that uses this low CO2 refrigerant since 2001. Although this refrigerant can be used for heating up to a certain temperature, it cannot be used in large commercial refrigerators and freezers because of its low cooling efficiency. However, with the support of the New Energy and Industrial Technology Development Organization (NEDO), the Panasonic Group developed a refrigeration system that uses this CO2 refrigerant, and has been delivering CFC-free freezers and refrigeration showcases that use this CO2 refrigerant to supermarkets and convenience stores since 2010. Their use has expanded to warehouses and food factories, and we have shipped a total of 25,000 units in the domestic market. In addition, overseas shipments have increased significantly over the past few years, and we started production at our overseas sites last fiscal year to expand market opportunities globally.

For wall-mounted home air-conditioners (AC), we are promoting changing over from non-inverter types of AC, not only to more eco-friendly inverter types of AC with high energy-efficiency, but also to the AC with new refrigerant R32 whose Global Warming Potential (GWP) is low. In fiscal 2020, we introduced into Hong Kong's window air-conditioner market new models with the industry's first inverter system using the new R32 refrigerant, which has contributed to reduce environmental loads.

In addition, as measures against ozone depletion caused by HCFCs, a refrigerant called R410 that does not deplete the ozone layer was used in room air conditioners; however, this substance has an issue of its very high very high Global Warming Potential (GWP). Therefore, the Panasonic Group developed a model that uses a new refrigerant R32, which has a lower GWP and introduced it launched sales of the model in 2013. Furthermore, PT. The Panasonic Manufacturing Indonesia, which owns the factory for manufacturing room air conditioners in Indonesia, redesigned its production facility that used an ozone-depleting HCFC refrigerant R22 to one using R32 in fiscal 2015, and started supplying new R32-based air conditioners. Thereby, we contributed to the Indonesian government's initiative to eliminate the use of HCFCs.

In May 2023, we started manufacturing air-to-water heat pumps that utilizes R290 natural refrigerant (propane) for residential use, which has extremely low Global Warming Potential (GWP), as the first Japanese manufacture. In this fiscal year, we introduced new products, and lineup expansion of our product is underway.

OCU-CR2001MVF, a fluorocarbon-free freezer using CO2 refrigerant

Restriction on Use of PVC Resin

Polyvinyl chloride (PVC) is a material of concerns to the generation of hazardous substances from inappropriate disposal, as well as the harmful effects of certain additive agents (phthalates) used to render PVC more pliable. In light of the significant potential for inappropriate disposal of the PVC resin used in the internal wiring of products, due mainly to difficulties associated with the sorting of this resin from used products, we have switched our new products launched from April 2011 to non-PVC.

Restriction on Use of Phthalates

Phthalates are often used in PVC products, and the use of four phthalates*7 was restricted under the EU RoHS Directive from July 22, 2019. Panasonic Group classified these substances as Level 1 Prohibited Substances in our Chemical Substances Management Rank Guidelines Ver. 11 (for products) issued in July 2018, and delivery of materials and components contain the phthalates was prohibited from July 22, 2018. We have classified other phthalates as Level 3 Prohibited Substances, and are promoting their substitution. Since phthalates have a migration characteristic (where a substance from another article migrates through contact), materials may be contaminated by migration from production facilities as well as process equipment containing the four phthalates, which are specified as Level 1 Prohibited Substances. Accordingly, we also discussed introducing preventive measures against contamination through contact. To build a structure for incoming inspection for phthalate, we amended the standard for incoming inspection and determined to conduct incoming inspections on supplied components with a high risk of containing phthalates, such as PVCs, elastomers and glues. We have already selected and assessed an analyzer for phthalates to use for these inspections, and installed the analyzer at our business division. The phthalates contained in Panasonic Group's products exported to Europe used to be as high as 10t. However, total elimination of the phthalates has been completed as of March 31, 2019.

*7 Bis(2-ethylhexyl) phthalate (DEHP), Butyl benzyl phthalate (BBP), Dibutyl phthalate (DBP), and Diisobutyl phthalate (DIBP).

Organic fluorine compounds

It is believed that there are more than 10,000 types of organic fluorine compounds known as perand polyfluoroalkyl substances (PFAS). Of these substances, per/polyfluorooctane sulfonate (PFOS), perfluorooctanoic acid (PFOA), perfluorohexane sulfonic acid (PFHxS) identified to be toxic, along with perfluorocarboxylic acids with a carbon chain length of 9 to 14 (C9-C14 PFCA) have been designated banned substances in the Chemical Substances Management Rank Guidelines (For Products), and their presence in Group products has been prohibited. In view of the deliberations under way in the EU, the United States and other countries regarding the regulation of other PFAS substances, we request our customers to disclose information that will allow us to assess the presence of such substances in Group products.

Activities to Reduce Negative Environmental Impact at Factories

The Panasonic Group has been working to minimize environmental impact by identifying the hazardous substances used in our products, assessing the impact of such use, and voluntarily discontinuing the use or reducing the release of such substances. Since 1999, we have been conducting the 33/50 Reduction Activity to materialize reduction by 33% in three years and by 50% in six years. In Japan, we started promoting reduction of amounts to use, release, and transfer specified chemical substances at our factories in fiscal 2000. Against the target in our voluntary action plan, a reduction by 50% from the fiscal 1999 level, we achieved a 75% reduction in the chemical substance use and a 62% reduction in the release and transfer in fiscal 2005. Since then, we have been continuing the activity, focusing on substances with particularly large amounts of release and transfer, setting a voluntary action target of reduction by 30% compared to the fiscal 2006 level. As a result, we achieved a 46% reduction in the amounts of release and transfer of specified key reduction-target substances across all factories worldwide in fiscal 2011.

Reflecting international trends in chemical substance management, our reduction measures have focused increasingly on particularly hazardous substances from fiscal 2011. Our Chemical Substances Management Rank Guidelines (for Factories) was established in 1999 as a guideline to help manage the above chemical substance reduction activities. In Version 1, the guidelines specified a list of chemical substances to be managed, mainly focusing on carcinogenic substances. The guidelines were later updated to Version 2 in 2000 to include rules concerning the Japan PRTR Law. Version 3, introduced in 2004, additionally covered a list of substances specified by chemical substances management legislation in Japan. The chemical substances covered by Version 4 and later from 2009 are those specified in legislation on human health and environmental impact in Japan, the U.S., and Europe, as well as those specified under international treaties.

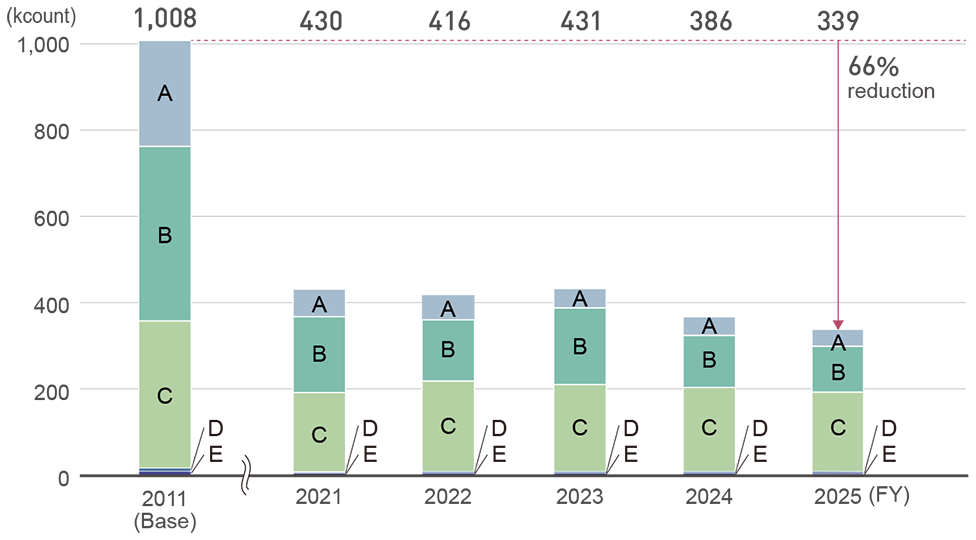

Under our Chemical Substances Management Rank Guidelines (For Factories), we have focused our management on select chemical substances that are hazardous to human health and the environment. Further, the Panasonic Group created a unique indicator, the Human Environment Impact,*8 which is used globally in all our factories. Conventionally the chemical substances were managed by "quantity," such as usage amount or emissions/release. However, such quantity-based management has a problem in that some highly hazardous substances do not become subject to reduction or management if the usage amount was small, and therefore would fall out of the scope of impact assessments. In addition, the toxicity criteria varied according to substance types and regional legislation, which made standardized management across the Group difficult. To address this issue, we worked together with experts from both within and outside the Group, reclassified chemical substances based on an overall assessment of their hazardousness, and specified a hazardousness factor for each classification.

Specifically, we set a hazard classification to each substance by utilizing carcinogen risk assessments issued by international organizations, together with publicly available hazard information and lists of ozone depleting substances.

For substances that have multiple hazard information items, the item ranked with the highest hazard risk is used for classification. We utilize this Panasonic Group internal indicator as the Human Environmental Impact indicator to promote efforts to ensure reduction of highly hazardous substances with greater environmental impacts, such as carcinogens and ozone depleting substances, according to the risk level. The Panasonic Group Chemical Substances Management Rank Guidelines is also available on the website on Panasonic Group Green Procurement activities to promote collaboration with our suppliers, encouraging them to offer materials that do not contain hazardous substances.

*8 Human Environmental Impact = Hazardousness factor x Release and transfer amount.

Further, we maintain our compliance in different countries by obtaining the latest information about the various chemical regulations enforced in each country through our overseas sites (former regional headquarters) and local industrial organizations. As for the VOC regulations amended in China in 2020, we successfully completed compliance confirmation and replacement with compliant components in each business division thanks to cooperation from local suppliers.

Classification of Hazards

| Classification | Hazards*9 | Hazardousness factor |

| A | Carcinogenicity/Ozone layer depletion | x 10,000 |

| B | Serious or direct impact | x 1,000 |

| C | Medium impact | x 100 |

| D | Small or indirect impact | x 10 |

| E | Minor impact or not assessed | x 1 |

| Classification | Hazards*9 | Hazardousness factor |

| A | Carcinogenicity/Ozone layer depletion | x 10,000 |

| B | Serious or direct impact | x 1,000 |

| C | Medium impact | x 100 |

| D | Small or indirect impact | x 10 |

| E | Minor impact or not assessed | x 1 |

*9 In addition to carcinogenicity, hazards to human health include genetic mutation, reproductive toxicity, and acute toxicity. In addition to ozone depleting substances, hazards to/substances with impact on the environment include ecological toxicity, substances that impact global warming, and substances that generate photochemical oxidants.

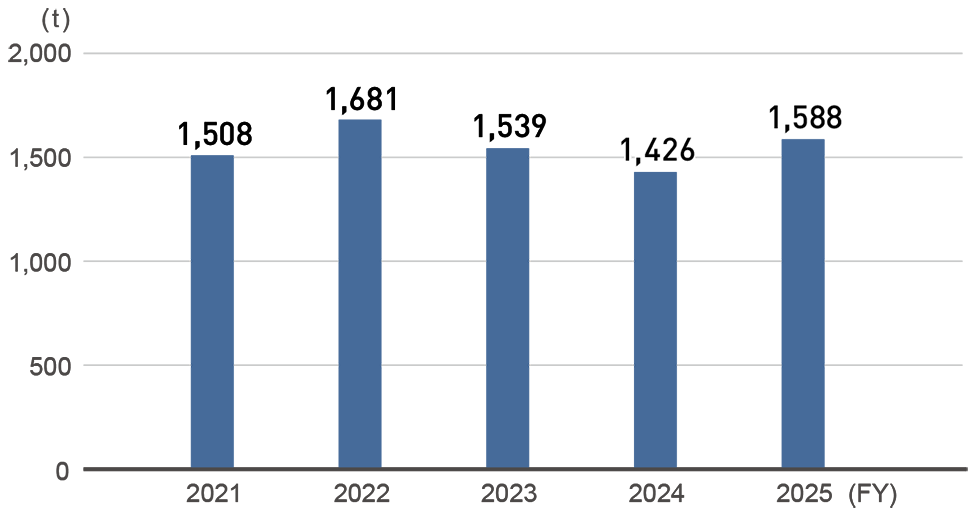

Human Environmental Impact

In fiscal 2025, we were able to reduce Human Environmental Impact by 66% compared with fiscal 2011. We will continue to implement our activities to minimize emissions of the substances with high environmental loads from our production activities.

VOC*10 Emissions

*10 Emissions of Volatile Organic Compounds (VOC) into the air caused by use. The calculation covers 100 major VOC substances that Panasonic Group selected from those listed in the Air Pollution Control Act.

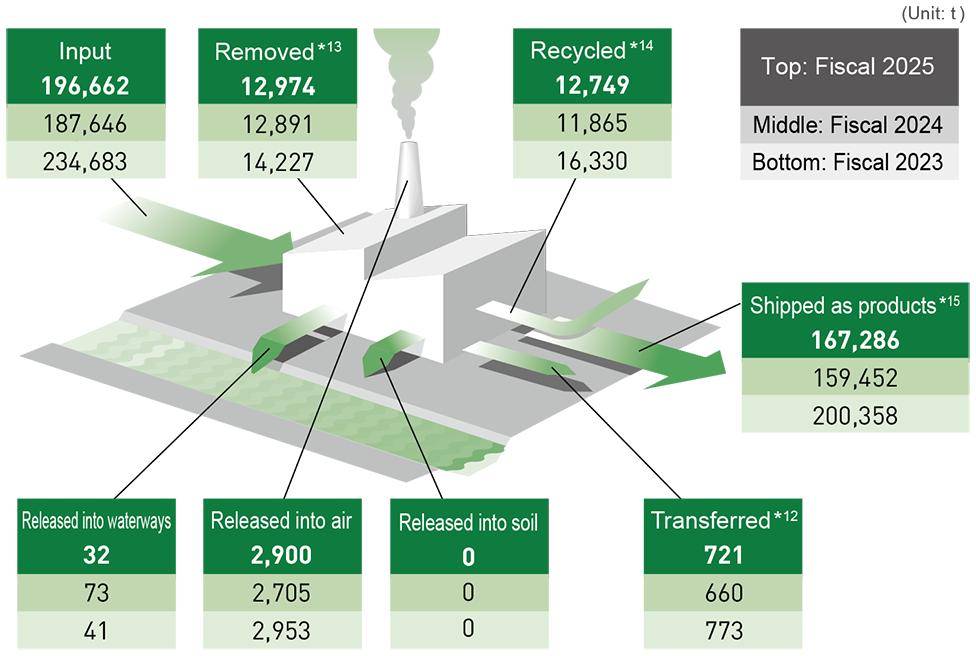

Material Balance of Substances in the Management Rank*11

*11 Based on the Chemical Substances Management Rank Guidelines (for factories). Includes all the substances specified in the Pollutant Release and Transfer Register Act.

*12 Includes substances transferred as waste, as well as those discharged into the sewage system. Recycled amount which is free of charge or accompanies treatment cost under the Waste Management Law is included in "Recycled." (Different from the transferred amount reported under the PRTR Law.)

*13 The amount of substances converted into other substances through neutralization, decomposition, or other chemical treatment.

*14 The amount of substances recycled with revenue, as well as those recycled free of charge or with any payment.

*15 The amount of substances that have been changed to other substances as a result of chemical reactions, and/or those that are contained in or accompanied with products and shipped out of factories.

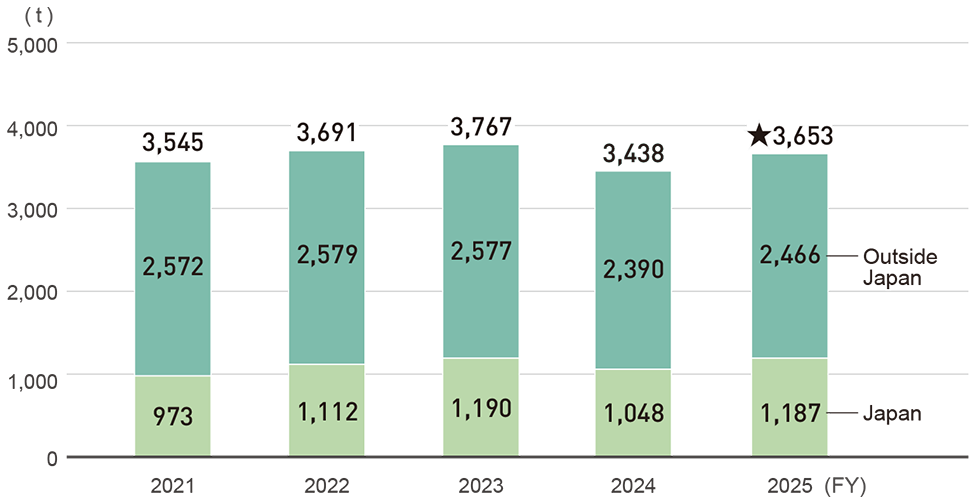

Release/Transfer of Substances Requiring Management*16

*16 Hussmann Parent Inc. and its consolidated subsidiaries not included.