Reducing CO2 Emissions in Transportation

In order to realize the 'Environmental Vision 2050' and contribute to the prevention of global warming, aiming to improve transportation efficiency while reducing costs, Panasonic has been working to reduce CO2 emissions also in our Distribution division, focusing on modal shift, adoption of low-emission vehicles, adoption of biodiesel fuels, reductions in transportation distances, and improvement of the loading rate in transportation/distribution.

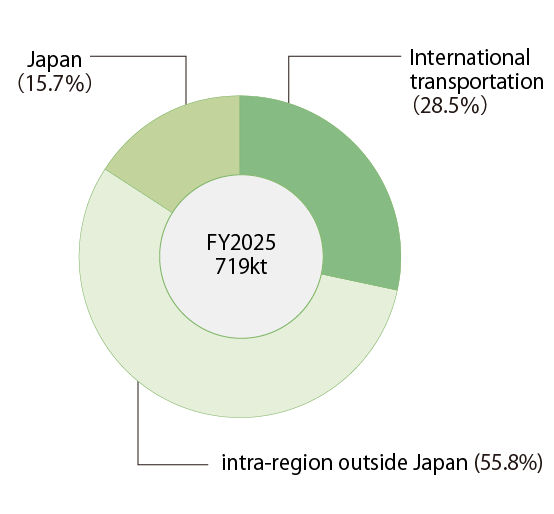

As a result, in fiscal 2025, our total global CO2 emissions from logistics activities was 719kt worldwide; of which international transportation was 205kt, and domestic transportation in Japan was 112kt.

CO2 Emissions from Logistics

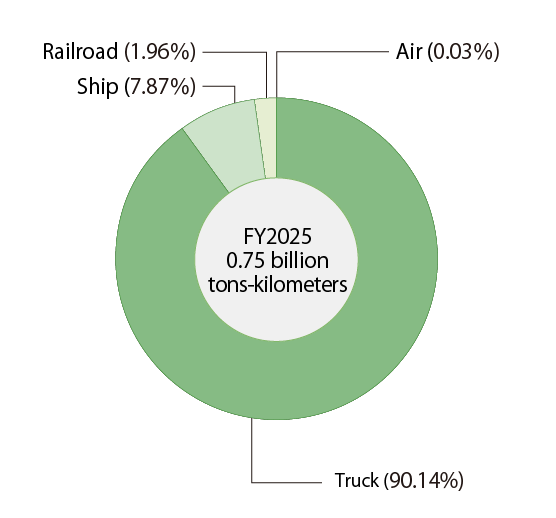

Transportation Amount by Transportation Method (Japan)

Consolidated Transportation (transportation/load of different products at the same time) in Collaboration with Sales Division

Making best use of that products are shipped from the same warehouse, Panasonic has transported products in consolidated cargo (transport/load of different products at the same time) in collaborating with its sales division. Under the system finalizes orders two days before the transportation, which was started in 2017, the followings have been realized: 1) allocation of a tack for the transportation one day before the transportation instead of on the transportation day, and 2) consolidated transportation of different products such as water heaters and air conditioners. As a result, the number of ordering trucks for transportation has been reduced, which has contributed to CO2 reduction, and at the same time, actions for transportation risk have been realized. In fiscal 2025, the total number of actually ordered trucks for consolidated transportation was 4,092 trucks (108% year-on-year), whose loading rate at the same time was 41%, and CO2 reduction effect was equivalent to 140t per year; for the subject transportation, 6.9% of CO2 was reduced.

Modal Shift Promotion Initiatives

At the Hikone Factory of the Beauty Personal Care Division of Panasonic Corporation Living Appliances and Solutions Company, conventional truck transportation has brought on multiple challenges, such as an increase in environmental impact and longer driver hours. In order to resolve these issues, we decided on a policy to switch our means of transport from trucks to JR Freight Railway transport, conducting on-site and actual item inspections and negotiations with relevant parties at JR Kyoto Freight Terminal. In order to realize this modal shift, we needed to extend the transportation lead time by one day, so we reviewed the inventory management system and month-end delivery rules. As a result, we were able to simultaneously reduce our environmental impact and solve logistics issues.

Specifically, we succeeded in reducing both CO2 emissions and driving time by approximately 70%. In addition, we achieved annual cost reductions of approximately 5 million yen, contributing significantly to the establishment of a sustainable logistics system.

For this undertaking we received the FY2024 Energy Conservation Award “Director-General of the Agency for Natural Resources and Energy Award.”

Landing Shipments at a Port Close to the Target Sales Area

Aiming for higher efficiency in transporting products, Panasonic is expanding its our efforts to land imported products at a port close to the target sales area in Japan. Conventionally, landing of products was centralized to a port near the West Japan Global Logistics Center (GLC) in Amagasaki City in Hyogo Prefecture, stored at the West Japan GLC, and then transported to respective locations as required. Landing the products at ports closer to the target sales areas can reduce the distance required for land transport within Japan, thereby contributing to reducing not only CO2 emissions but also inbound and outbound deliveries between sites as well as distribution costs. In fiscal 2025, we further improved the accuracy of our efforts to land shipments close to the target sales area. We started this with televisions, which we had been working on for some time because of their high sales volumes, and also extended it to massagers, irons, recorders, portable televisions, telephones. In particular, headphones and rice cookers whose production has been transferred overseas have started to be delivered to East and West GLC and we further reduced our domestic transportation. From now on, we will continue to expand the scope of products and also further refine the projection of sales demand in various regions, optimize the stock amounts held in those areas, and expand the landing products at ports near target sales areas.

Introduction of Biogas Trucks

Panasonic Energy Co., Ltd. is working to reduce CO2 emissions in product distribution. In addition to promoting the optimization of transportation methods and routes, in cooperation with EcoTruck Co., Ltd., we have been conducting demonstration tests in Japan on a biogas-fueled truck that can be regarded as having zero CO2 emissions during operation in place of conventional diesel trucks. This approach is scheduled to be put into practical use in some areas in 2025, and we are planning to expand the scope of its application to include the procurement and logistics of raw materials.

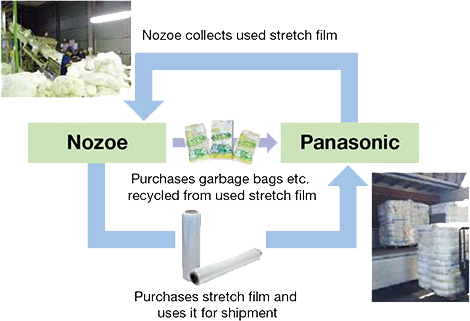

Recycling of Stretching Film Used in Shipment

As an activity to reduce logistics waste, in fiscal 2015, we started recycling and reusing used stretch films with Nozoe Industry Inc. (Nozoe), and in fiscal 2025, we have continued the activity. It used to that all the stretch films used for shipment were discarded after use, however, the used films are now recycled and used as raw materials for polyethylene bags by Nozoe, while Panasonic has purchased the bags made of recycled materials. As Chinese government started banning imports of waste plastics in the end of 2017, Panasonic’s other sites who did not have business contact with Nozoe in Japan started similar activities with Nozoe. In addition, with the launch of full operation of Nozoe’s recycling factory in Saitama Prefecture led to expand our recycling scheme for used stretch film in Kanto region. As a result, the total 314t of stretch film was recycled. We continue to make effective use of used stretch films, while reducing logistics wastes.

Stretch Film Recycling Scheme with Nozoe

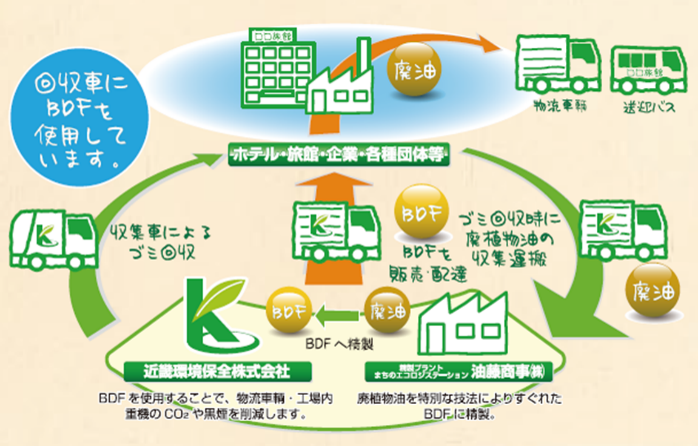

Use of Biodiesel Fuel

Panasonic promotes transforming waste cooking oil collected from its business sites into biodiesel fuel and utilizing it for vehicles used in production, procurement, and marketing activities. Since fiscal 2024, we have received support from Aburatou Shoji K.K., which is a manufacturer and seller of biodiesel fuel, and have been working to further expand the use of biofuel by supplying 5% biodiesel fuel to the vehicles owned by Kinki Kankyo Hozen K.K., which collects and transports waste from our Kusatsu site. The amount of biofuel we used in fiscal 2025 was 399 liters.

*The amount of biofuel used includes the amount from Revo International Inc.