Evolution of Recycling-Oriented Manufacturing

Evolution of Recycling-Oriented Manufacturing

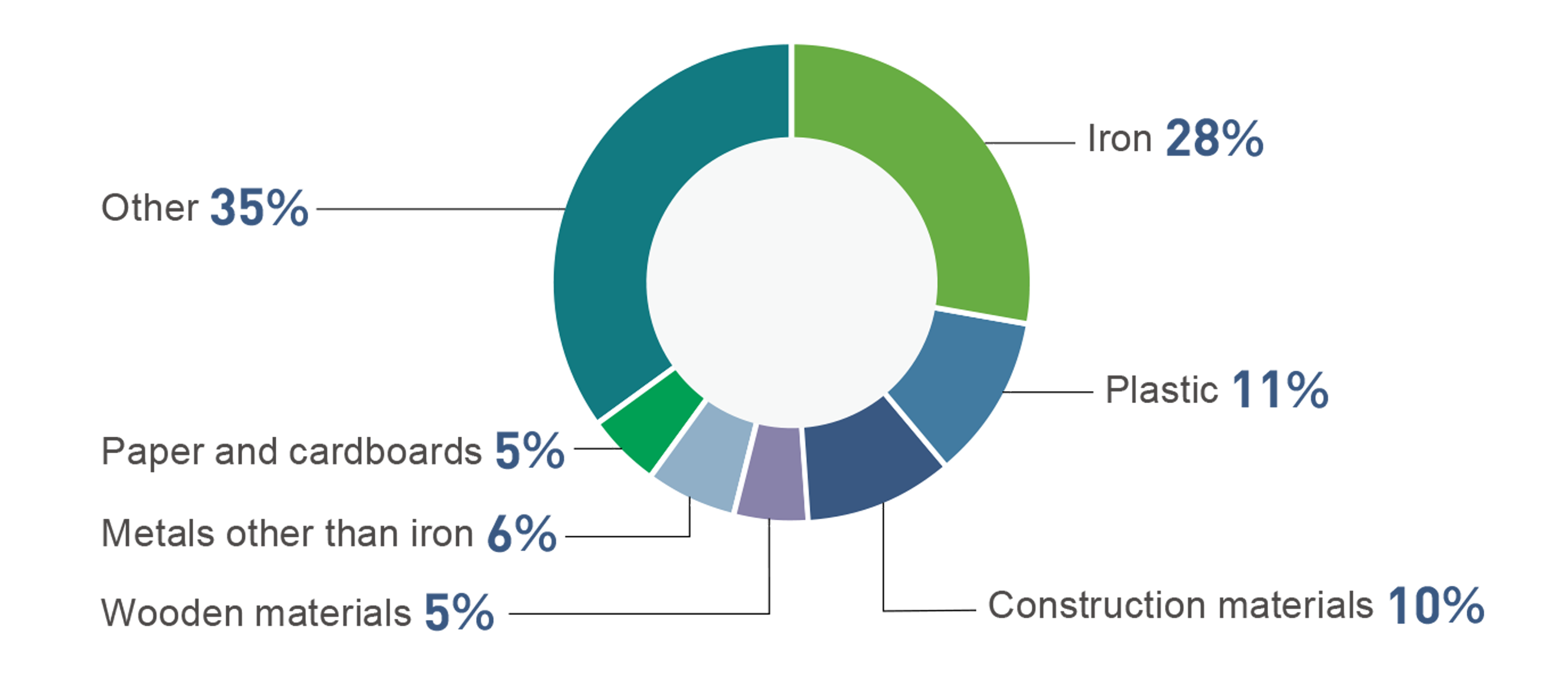

We use many kinds of resources, including iron (28% of total resources used) and plastic (11% of total resources used), because of our wide range of products and businesses, from home appliances, components such as semiconductors and batteries, housing, and B2B solutions. In recycling-oriented manufacturing, we are further working on reducing the input of virgin resources, while increasing the amount of recycled resources. And in that context, we are working to establish a circular system according to resource type and features.

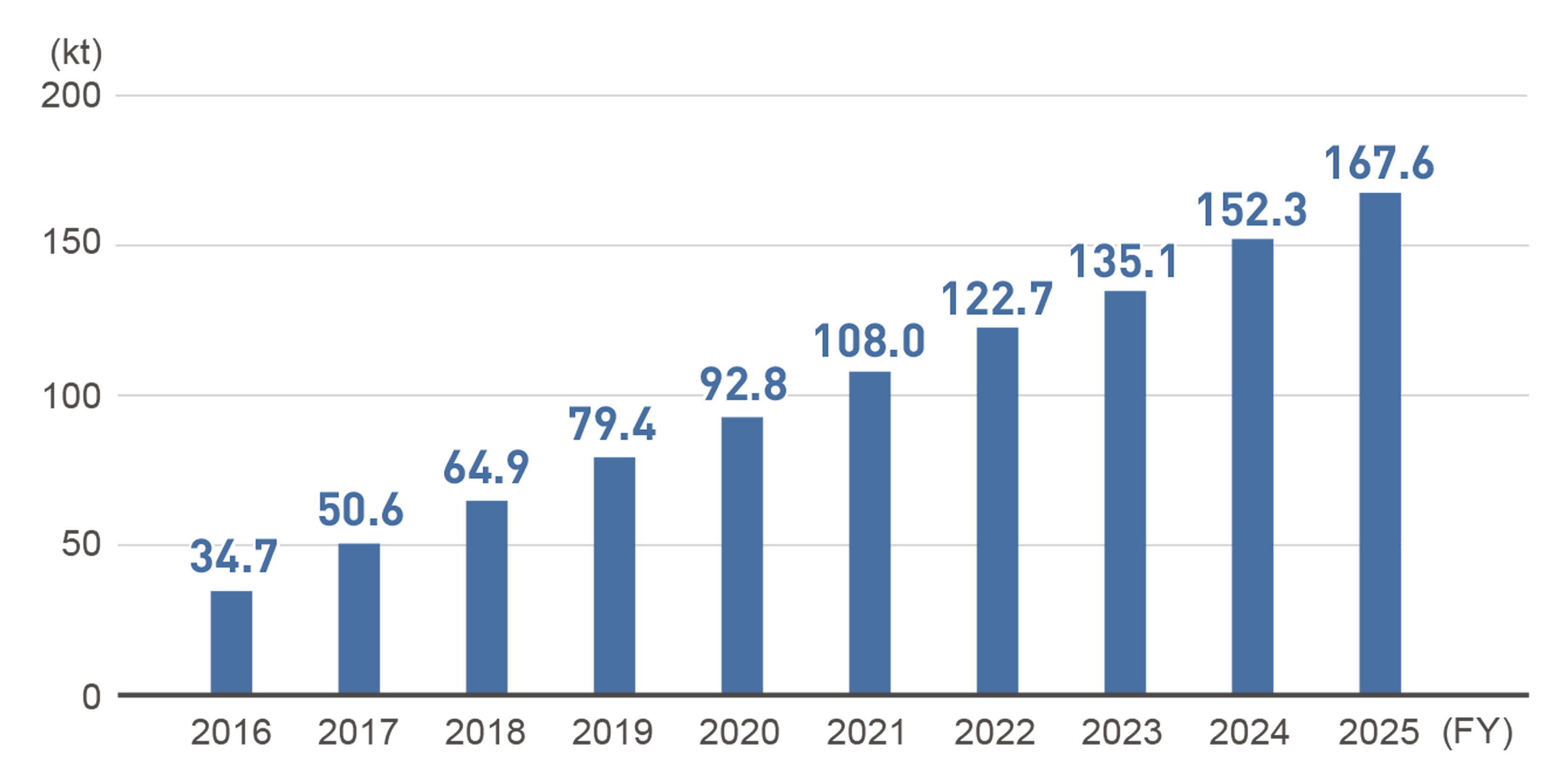

Furthermore, we are clarifying the use of recycled resource use by identifying the volume of each type of resource used across the Panasonic Group. For example, the case of recycled resin, we used approx. 15,000 tons of recycled resin in our products in fiscal 2025 bringing the total usage since fiscal 2023 to 45,000 tons. This was achieved by producing resin that has characteristics suitable for its usage purposes, securing stable supply, establishing adaptability in production sites to use the recycled resin, and developing recycling technologies. However, the above efforts did not meet the required level, and therefore we could not attain the GIP2024 target. We plan to accelerate our efforts to address these issues to steadily increase use of recycled resin. Moreover, we are promoting the development of plant-based resin with lower environmental impact and its application for the products.

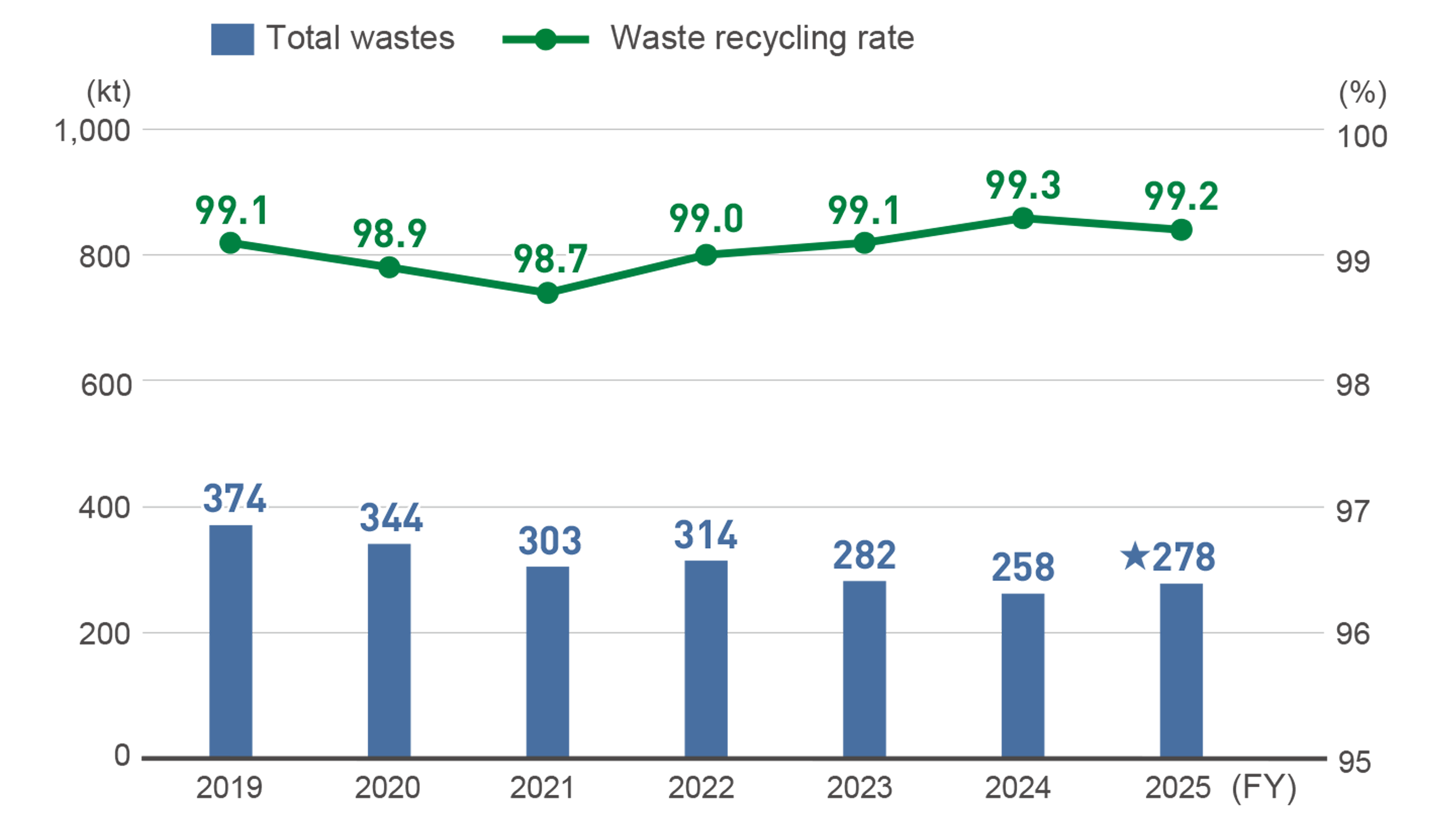

As for the factory waste recycling rate*1, we had traditionally set different targets for Japan and countries outside Japan according to the relevant local infrastructures. However, given increased awareness of the importance of zero waste emission activities, we have set a globally standardized target since fiscal 2011 and are taking steps to improve the standard level of waste recycling across the entire Group. The factory waste recycling rate in fiscal 2024 was 99.2% compared to our target of more than 99%, achieving the target. We will continue to implement measures to achieve the zero waste emissions.

*1 Factory waste recycling rate = Amount of resources recycled/(Amount of resources recycled + Amount of landfill)

Breakdown of Total Resources Used in Fiscal 2025 (by category)

Results of Recycled Resin Usage (Cumulative total from fiscal 2015)

Reduction in Resources Used

To minimize the use of resources for production, we continuously look to reducing the weight of our products. Through the Product Environmental Assessment, we have been promoting resource saving from the product planning and design stage, such as using less resources, making our products lighter and smaller, and using less components. We also implement various measures from the standpoint of resource recycling throughout the product life cycle, such as component reuse, longer durability, use of recycled resources, easier battery removal, and labels necessary for collection/recycling.

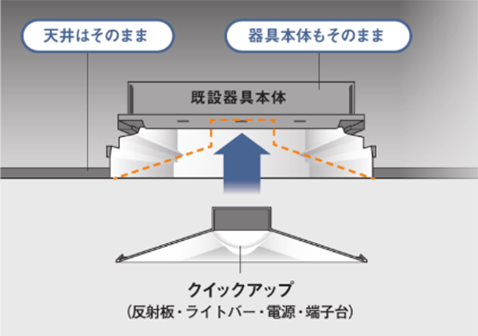

Quick-Up, a remodeling unit dedicated to the upgrading of system ceiling lighting equipment

Since the reflector plate is equipped with a power supply component, it is possible to upgrade a fluorescent lighting fixture with a straight tube LED or an iD series lighting fixture by utilizing the existing embedded type and system ceiling type body. Because this product utilizes the main body of an existing fluorescent lighting fixture, it enables upgrading with an LED lighting fixture in a short work period and can reduce the environmental load by producing less waste material.

Hair dryer

Launched in September 2022, the EH-NA0J nanocare hair dryer builds on the previous nanocare model. Equipped with high-permeation nanoe, the EH-NA0J moisturizes up through the tips of hair.*2

The new design features a compact and lightweight body, and its size is approximately 27% less than the EH-NA0G released in 2021. It also reduces energy consumption through its enhanced drying performance, and provides the largest air volume in the history of nanocare in Japan. By saving resources and reducing environmental burdens, it contributes to the realization of a sustainable lifestyle and society. In addition, the successor model EH-NA0K, which will launch in September 2025, uses plant-based biomass paint in all four colors, reducing petroleum resource consumption*3.

LAMDASH PALM IN

The "LAMDASH PALM IN" ES-PV6A we launched on September 1, 2023 condenses five-blade technology into a palm-sized shaver that has approximately 70% the volume of the existing LAMDASH PRO five-blade ES-LV9W.*4 It offers a new experience of shaving like stroking the skin while feeling the condition of the skin through the fingertips. We also use the innovative composite material "NAGORI®" that was created from mineral components extracted from seawater. This reduces the amount of plastic used by approximately 40% and also gives the product a texture that feels like pottery. In addition to use in the home, the USB-C charging and the carrying case supplied mean that it can also be used in various situations such as in the office and during business trips and travel.

Examples of recyclable product design

In order to make recycling more efficient, we are working on designs that make it easy to disassemble and sort according to industry guidelines. For example, in order to make products easier to disassemble, we do away with fixing methods that are difficult to disassemble, such as welding and caulking, and reduce the number of screws used. In addition, we are also displaying the material of resin parts to make it easier to sort them.

Use of Sustainable Materials

Under the concept of "product-to-product", we are enhancing our initiatives of utilizing resources recovered from used products. As for resin, we promote the reuse of resin recovered from our used home appliances (refrigerators, air conditioners, washing machines, and TVs) for our products. We also started recycling scrap iron recovered from used home appliances in our products in 2013.

In addition, as an example of "product-to-product" use, we are aiming to realize "battery-to-battery" recycling. With the cooperation of AEON RETAIL Co., Ltd., we are installing boxes for the collection of used dry-cell batteries in stores and collecting the used dry-cell batteries that have been sold at AEON RETAIL stores. We are recycling the collected dry-cell batteries into new materials such as steel materials through the Okayama Plant of Tokyo Steel Co., Ltd., and are also utilizing the batteries in research and development aimed at recycling them into dry cell components. Through this initiative, we will research and establish an efficient collection and recycling process for used dry-cell batteries, and also aim to realize battery-to-battery recycling.*5

Battery-to-battery recycling is also being implemented for lithium-ion batteries for automobiles. Our Group has had a partnership with Redwood Materials, Inc., a U.S. battery recycling company, since 2019, and in 2022 concluded a sales agreement for cathode materials and copper foil obtained through the recycling of automotive lithium-ion batteries*6. Research and development is being carried out to have Redwood Materials recycle the waste batteries and process waste from our Group into cathode materials for use in batteries. By producing batteries made from recycled materials, we can reduce CO2 emissions generated during mining and promote recycling-oriented manufacturing.

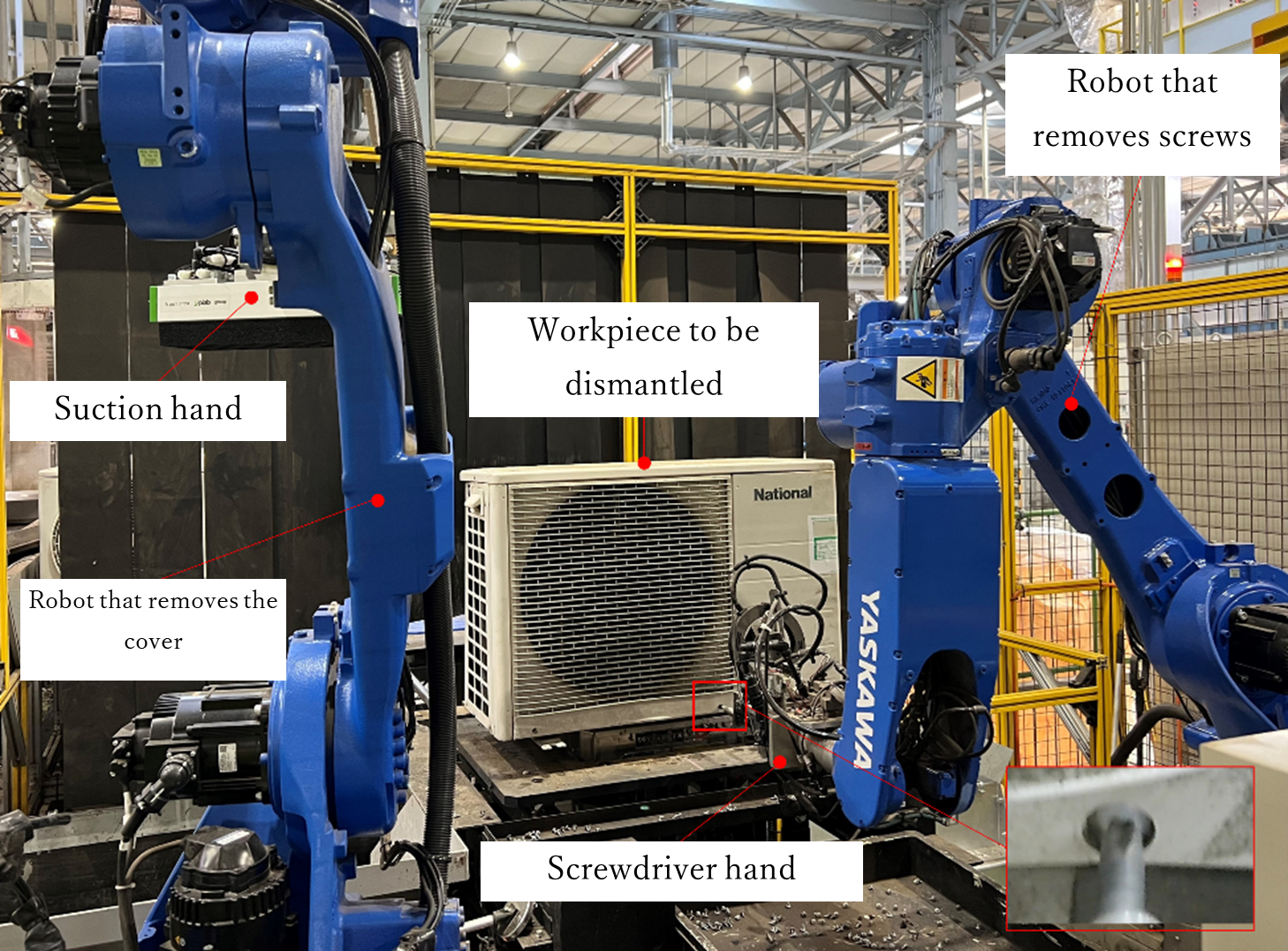

Furthermore, we are also conducting development for greater efficiency and automation in the extraction of resources from used products. For the dismantling process for air conditioners, we have collaborated with Panasonic Eco Technology Kanto Co., Ltd. and Mitsubishi Materials Corporation and developed an automatic dismantling system for the covers on air conditioner outdoor units. This system includes automatic dismantling equipment with robots that dismantle the outdoor units of air conditioners, and a dismantling database that stores the information required for the dismantling*7. Furthermore, in collaboration with Panasonic Production Engineering Co., Ltd., and Hirakin Co., Ltd., we are aiming to further increase the efficiency of work to dismantle used home appliances and have developed an automatic dismantling system for used home appliances which focusses on air conditioner outdoor units. In the recycling of home appliances, this system is the first in the industry to enable integrated processing from the appliance input to the dismantling of each part*8. In addition to these efforts, we are promoting "Design for CE*9" (Circular Economy), which will enable products to be used for a long period of time by simply evaluating the ease of assembly and disassembly at the design stage and improving repair and maintenance performance.

Enhanced Use of Recycled Resin

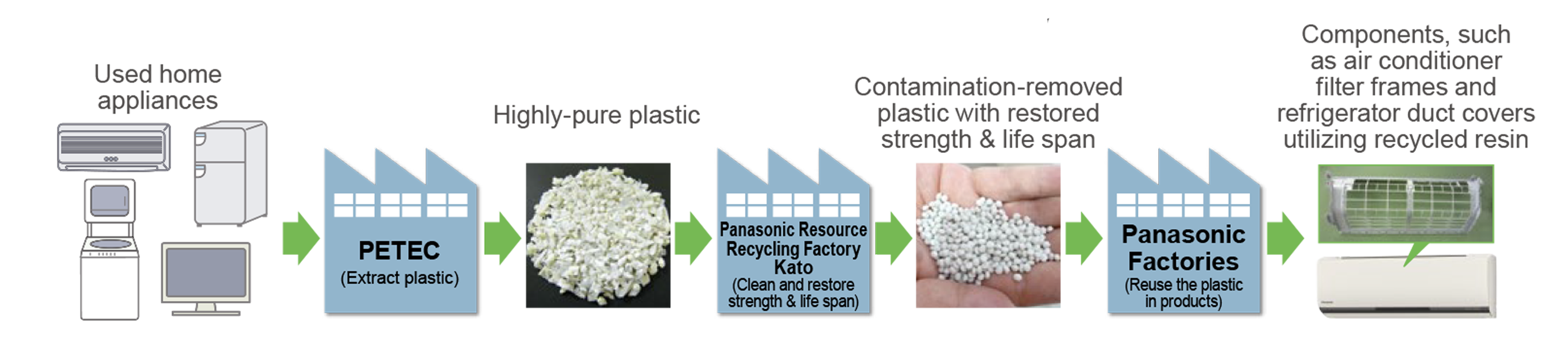

To efficiently utilize resin recovered from used home appliances in addition to metals such as iron, copper, and aluminum, our recycling factories— Panasonic Eco Technology Center Co., Ltd. (PETEC), and Panasonic Resource Recycling Factory Kato (PRRFK) of the Living Appliances and Solutions Company— work together for resin recycling.

Process of Resin Recycling

Using technologies such as our original near-infrared identification technology, PETEC is capable of sorting shredder residue of waste home appliances into three major types of resins with different purposes and properties—polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polystyrene (PS)—at a material purity of over 95%.

The recycled single resins sorted and recovered at PETEC are then transferred to the adjacent Panasonic Resource Recycling Factory Kato to be further purified and processed to recover their chemical properties. Panasonic Resource Recycling Factory Kato (PRRFK) is a manufacturing and development site that promotes the use of recycled resin at our Living Appliances and Solutions Company, a home appliance manufacturer and seller. The factory plays an important role in enhancing recycled resin utilization by developing recycling technologies, such as a more efficient method that improves the performance of recycled resin. Generally, the strength and lifespan of resin deteriorate over time. This is why its chemical properties have to be recovered to the level of new resin to make them usable as materials and components in new products. Due to the differences in the physical properties required by different products, we have been examining the properties of recycled polypropylene, polystyrene and acrylonitrile butadiene styrene, and have developed technologies to create new formulas for resin components, adding our own proprietary antioxidant and mixing recycled resin with new resin. To increase usage of recycled plastic across Panasonic Group, we plan to find recycled plastic suppliers based on the recycled plastic development and quality assessment techniques cultivated in our Panasonic Resource Recycling Factory Kato.

Near-infrared sorting machine that can sort three types of resin simultaneously

Development and Use of New Sustainable Materials

Cellulose fiber is made from natural resources such as pulp and wood chips and is drawing social attention as a material with low environmental impact. In fiscal 2016, we commenced research and development into cellulose fiber aiming to reduce the use of fossil-based resin. In fiscal 2019, we successfully produced an easy-to-use molding material that is as flexible as conventional resin while reducing the use of fossil-based plastic by mixing plant-based cellulose fiber at a high concentration level into the resin. We further increased the cellulose fiber concentration level, and released these materials under the brand name, "kinari". In 2022, we started mass production and sales of kinari55-PP, a resin made with 55% cellulose fiber*10. Then in 2024, kinari70-PP, a resin with 70% cellulose fiber followed*11. Within the same year, we commenced sample sales of kinari90, which is 90% biomass resin made by combining cellulose fiber and 90% or greater biomass polyethylene produced from sugarcane bagasse (pulp left after the juice is extracted)*12 .

To achieve complete biodegradation of molding materials, we have been working to blend cellulose fibers into biodegradable resins. In fiscal 2022, we succeeded in developing a molding material based on plant-derived resins (polylactic acid, etc.) that completely decomposes in soil*13, *14. In order to further reduce the risk of environmental pollution in the event of discharge into the natural environment, we also improved our compounding and molding technologies to enable biodegradation in the marine environment, where decomposition is difficult. In fiscal 2024, we succeeded in developing a cellulose-fiber molding material with 100% biomass*15 by replacing the resin mixed with cellulose-fiber with a marine biodegradable resin that is completely degradable in the ocean and has the same strength as the polypropylene used for durability applications. As with the conventional kinari series, these biodegradable materials have also been successfully pelletized into white resin that can be colored freely, enabling a high level of flexibility with regard to design. The molding materials developed have received the Biodegradable Biomass Plastic and Marine Biodegradable Biomass Plastic marks certified by the Japan BioPlastics Association.

Further, we are working to increase the strength of the cellulose fiber molding materials to expand our kinari applications to be an alternative to fossil-based resin. We produced a material that demonstrates a strength equivalent to PBT-GF30% (polybutylene terephthalate with 30% glass fiber) at 80°C utilizing our newly developed plastics engineering compounding technology. We have also successfully developed cellulose-fiber molding materials with less density*16.

The cellulose fiber used as the raw material for kinari is not only made from virgin materials, but also from other materials that previously would have been discarded. We are developing molding materials that use lumber from tree thinning, waste wood, hemp and cotton fabrics, and even coffee and tea grounds, establishing a cycle that contributes to reducing environmental impact while reducing waste*17.

Relating to "kinari" production, we are reinforcing relationships with local communities to utilize their regional resources under collaboration. Among these collaborative projects, we concluded an agreement with Fukuchiyama City, Kyoto Prefecture, to use their timber from forest thinning. We also jointly commercialized our eco-friendly tableware using this timber. On September 4, 2023, all 23 municipal primary schools and junior high schools in Fukuchiyama City started using some 6,700 sets of this tableware for their school lunches. At the same time, all these schools started an environmental education program in which we cooperated by providing the program contents. Another collaboration with a local company took place in Okinawa Prefecture. Together with Food Reborn Co., Ltd., in 2024 we developed a kinari tumbler utilizing pulp from Okinawan pineapple leaves*18, *19.

Such efforts relating to our kinari resin have earned a high social reputation and resulted in a number of awards, including the MEXT Minister's Prize under the FY2021 50th Japan Industrial Grand Prize held by Nikkan Kogyo Shimbun, Ltd., and the Contribution Prize under the 57th Ichimura Industrial Awards, hosted by the Ichimura Foundation for New Technology in April 2025*20.

-

*10 https://news.panasonic.com/jp/press/jn190708-1

-

*11 https://news.panasonic.com/jp/press/jn210204-1

-

*12 https://news.panasonic.com/jp/press/jn220318-2

-

*13 https://news.panasonic.com/jp/press/jn221206-1

-

*14 https://news.panasonic.com/jp/press/jn221206-1

-

*15 https://news.panasonic.com/jp/press/jn250108-8

-

*16 https://news.panasonic.com/jp/press/jn250515-2

-

*17 https://news.panasonic.com/jp/topics/205877

-

*18 https://news.panasonic.com/jp/press/jn230825-2

-

*19 https://www.city.fukuchiyama.lg.jp/site/kyouiku/59063.html

-

*20 https://news.panasonic.com/jp/press/jn250421-2

In the area of housing materials, we exclusively developed a wood-based flooring substrate that utilizes 100% recycled wooden materials (excluding glue) made from construction waste and unused materials. Thanks to our wide-ranging processing technologies, we successfully created a substrate with high density with superior solidity compared with general plywood and which offers excellent scratch and dent resistance. The starch in wooden materials can attract insects (lyctus), however, our product is insect resistant as it has a low starch content. The substrate also offers excellent scratch and dent resistance and is therefore ideal for coping with wheels on chairs and furniture. The board's tongue and groove structure is also designed to deliver easy installation. Further, a part of the sales revenue from this sustainable flooring is donated to Gunma Prefecture's forestry fund. The entire life of the floorboarding is consistent with an approach. This product can reduce the consumption of natural materials and also contributes to preserving biodiversity.

We intend to develop more new products with this technology, focusing also on developing new recyclable resources.

Impact of Iron Resources on Ecosystems

Our Group uses a wide variety of mineral resources in a wide range of fields, from home appliances, electronic components, and batteries to housing and B2B solutions. These mineral resources have various impacts on the ecosystem throughout the value chain, including mining, processing, use, and disposal, so it is important to appropriately understand and manage risks.

We are analyzing environmental and operational risks by focusing particularly on iron resources, which are used in large amounts. Risk analysis was conducted at each of the value chain stages: mining and processing, manufacturing, use and disposal, and recycling and reuse.

For the mining stage, there are concerns about habitat fragmentation and biodiversity loss due to deforestation and encroachment into protected areas. There is also a risk that the large amount of water used during mining could cause heavy metal and chemical runoff, polluting local water resources. Furthermore, greenhouse gas emissions associated with mining and processing may exacerbate climate change.

At the manufacturing stage, greenhouse gas emissions are a challenge because the energy used to produce iron depends mainly on fossil fuels. However, due to differences in raw materials, electric furnace steelmaking (recycled steel) emits less greenhouse gases than blast furnace steelmaking (virgin steel). There is also a risk of soil and water pollution from slag generated during the manufacturing process, so proper management is required.

At the use and disposal stage, waste management plays an important role in reducing the environmental impact of iron resources.

For the recycling and reuse stage, promoting the recycling of iron products can significantly reduce the environmental risks from waste. Therefore, establishing recycling-oriented schemes, including closed-loop recycling, is essential for sustainable resource management.

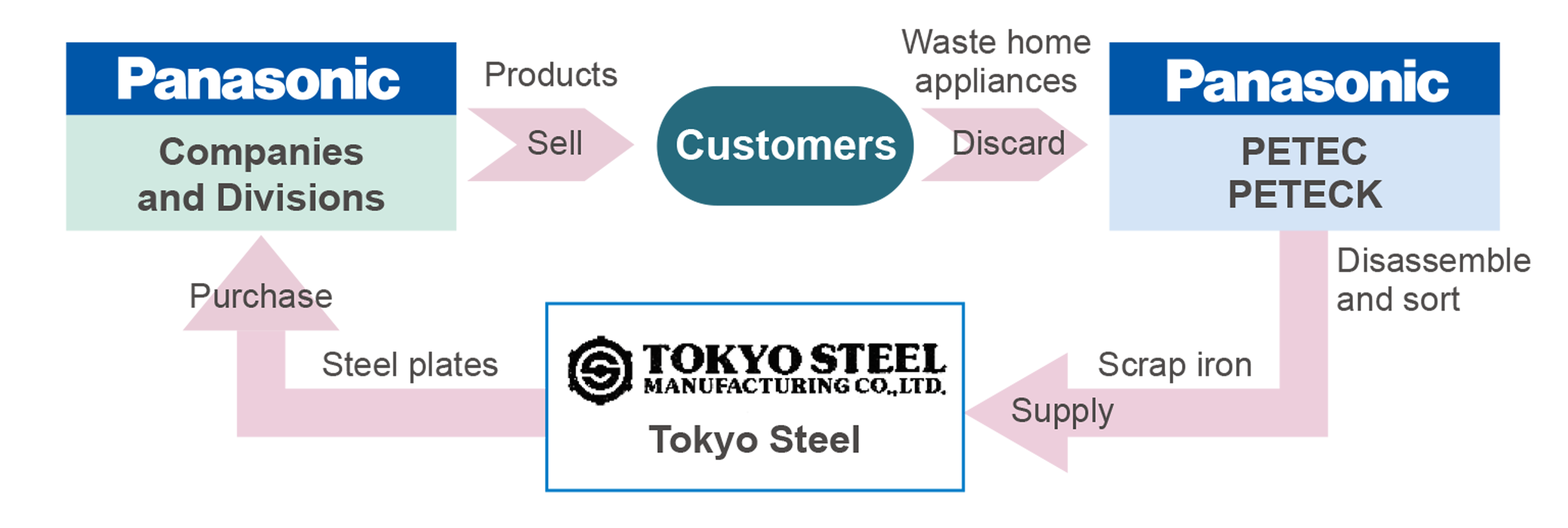

Building a Recycling Scheme for Scrap Iron

Jointly with Tokyo Steel Co., Ltd., we started a recycling scheme for scrap iron in July 2013. In this scheme, we recover the scrap iron from used home appliances and Tokyo Steel makes it into steel sheets. We then purchase the sheets back as a material for our products. Supplying scrap iron for recycling and repurchasing the recycled iron is the first scheme of its kind in the Japanese electrical manufacturing industry.

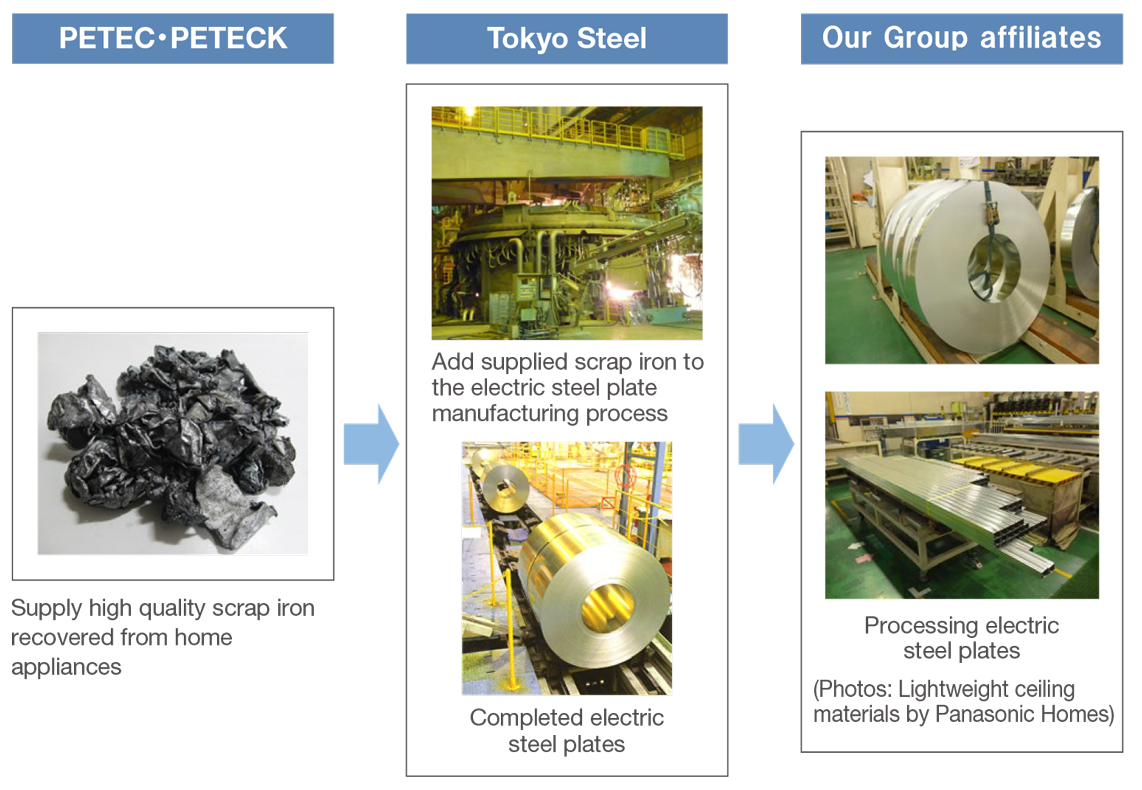

Self-recycling Scheme for Electric Steel Plates

Specifically, scrap iron from home appliances collected and treated at PETEC and Panasonic Eco Technology Kanto Co., Ltd. is supplied to Tokyo Steel, where the scrap iron is processed into electrical steel plates.*21 We procure the recycled steel plates and utilize them in products. Discussions with Tokyo Steel commenced, and we have worked together since then to improve the quality of recycled iron to a level sufficient for production use, as well as developing the technology to improve the applicability of the recycled iron. From this we identified the optimum application of the electrical steel plates, and refined its specific features (e.g. shape, strength, and weldability) to meet application-specific requirements. The use of thin electrical steel plates in our products was first made possible. Through this close collaboration, we materialized this recycling scheme, a scheme where a home appliance recycling company that we own supplies scrap iron to be used to make electrical steel plates.

The amount of scrap iron we initially supplied to Tokyo Steel was about 50 t per month. In fiscal 2025, it reached over 1,600 tons per year, and the recycled steel is being used in our Group products, including washing machines and ceiling materials for housing.

*21 Steel produced from scrap iron melted and refined in an electric arc furnace.

Self-recycling Scheme Process

The increase in electrical steel plate usage leads to an increase in the usage of scrap iron, which is one of the most important resources in Japan. In addition, producing steel plates from scrap iron emits much less CO2 compared with producing steel plates from scratch. This scheme also stabilizes the procurement price, because the price of scrap iron supplied from PETEC and the price of electric steel plates procured from Tokyo Steel are determined by the scrap iron fluctuation rate agreed between the two companies. Our Group has collaborated with Panasonic Homes, which is a joint venture in which Panasonic Holdings has a partial stake, and has also implemented the same scheme for the electric furnace steel sheets supplied to Homes. In addition to increasing the purchasing power of the Group and its affiliated companies as a whole, this also makes it possible to further reduce CO2 emissions. We will further expand this recycling scheme for more efficient resource utilization, CO2 emissions reduction, and stabilization of procurement prices.

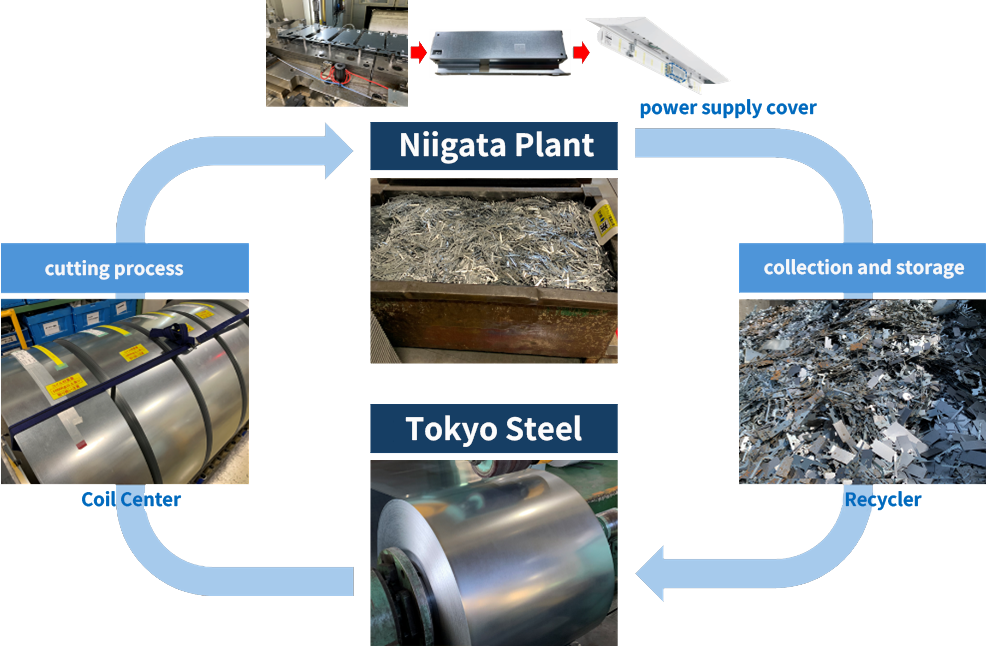

Beyond used products, we also recycle waste generated from factories. In Niigata Plant, we supply iron scrap generated during production to an electric arc furnace manufacture and utilize the iron recycled by the manufacturer in some of the products made in the plant*22. This trial of making iron from scrap supplied by our plant and then utilizing the recycled iron in the same plant is the first of its kind within the Panasonic Group. We are also running a similar scheme for resin.

*22 See https://www2.panasonic.biz/jp/lighting/facilities/baselight/id/

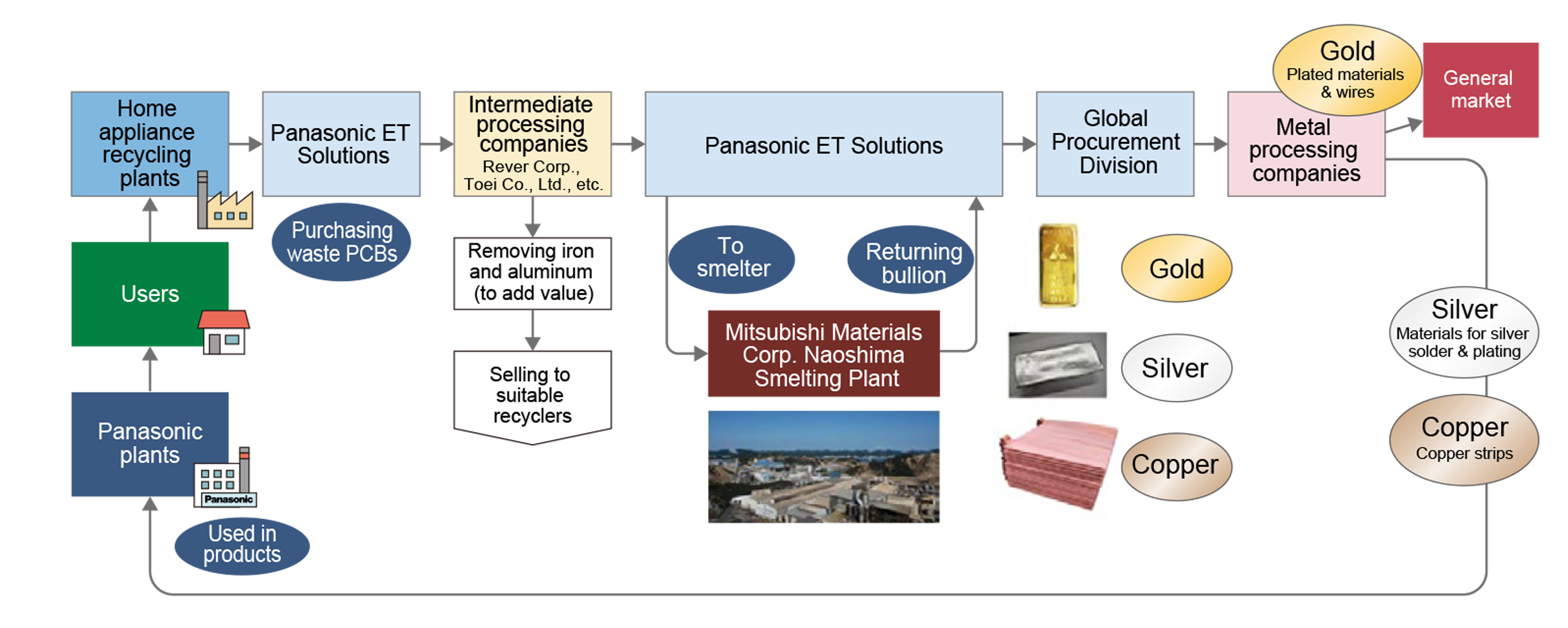

Gold, Silver, and Copper Recycling from Waste PCBs

The Panasonic Group is running the Product-Material-Product (PMP) Loop scheme together with Mitsubishi Materials Corporation. In this scheme, gold, silver, and copper are extracted from waste printed circuit boards (PCBs) formerly installed in our home appliances, and reused within and outside the Panasonic Group*23.

The scheme works as follows: One of our group companies, Panasonic ET Solutions Co., Ltd. (PETS), recovers waste PCBs from home appliance recycling plants and repair sites across Japan, and commissions initial waste processing to our recycling partner companies.

The recycling companies remove the iron and aluminum during shredding and smelting to improve the quality of waste PCB materials. The processed PCBs are then passed to Mitsubishi Materials. Mitsubishi Materials extracts gold, silver, and copper from the waste PCBs through smelting and returns the materials to PETS. The recovered gold, silver, and copper are made into gold plating solution, copper wire, etc. to be utilized in our products again. Total amounts of recovered metals from the waste PCBs through the PMP Loop scheme to date have reached 1.1 tons of gold, 33 tons of silver, and 8,100 tons of copper*24.

*23 See https://news.panasonic.com/jp/press/jn250117-4

*24 Based on the research of our Group and Mitsubishi Materials Corporation as of December 2024.

Zero Waste Emissions—Improving Factory Waste Recycling Rate

From the viewpoint of effective usage of resources, we believe that generation of waste and revenue-generating waste at factories must be minimized, even if such waste could be sold as valuable commodities. Based on this belief, we identify the amount of generated waste (including both revenue-generating waste and factory generated waste) and classify it into: (1) recyclable waste (including those that can be sold and those which can be transferred free of charge or by paying a fee), (2) waste that can be reduced by incineration or dehydration, and (3) landfill (waste with no option other than being sent to landfills). We reduce the emission of waste by boosting yield in our production process and increasing the recycling rate of our waste materials. Accordingly, we strive globally toward achieving our Zero Waste Emissions from Factories*25 goal by reducing the amount of landfill to nearly zero. As a result of various activities, the factory waste recycling rate in fiscal 2025 was 99.2%, achieving the 99% target in our GIP 2024. In addition to the waste plastic recycling, we will introduce more recycling activities which aim to maintain and improve the factory waste recycling rate.

As an initiative to reduce the amount of final disposal of waste and valuables, we will reduce the amount of materials that are particularly difficult to recycle, such as thermosetting resins. We are also strictly adhering to waste sorting practices in production processes to further expand the reuse of resources.

Because waste recycling rates in our overseas factories lag behind those in Japan, we have worked to improve the average level of recycling activities by sharing information within and between regions outside Japan. Specifically, in addition to accelerating the information sharing on waste recycling issues between our local factories and group companies in Japan, we also promote the sharing of excellent examples and know-how among our factories across regions by utilizing BA Charts*26 prepared by each region, following our long-standing approach toward CO2 reduction activities.

*25 Definition by the Panasonic Group: Recycling rate of 99% or higher.

Recycling rate = Amount of resources recycled/(amount of resources recycled + amount of landfill).

*26 A chart-format summary of comparisons between "before and after" implementation of waste reduction and recycling measures.

Amount and Recycling Rate of Total Wastes

Including Revenue-generating Waste

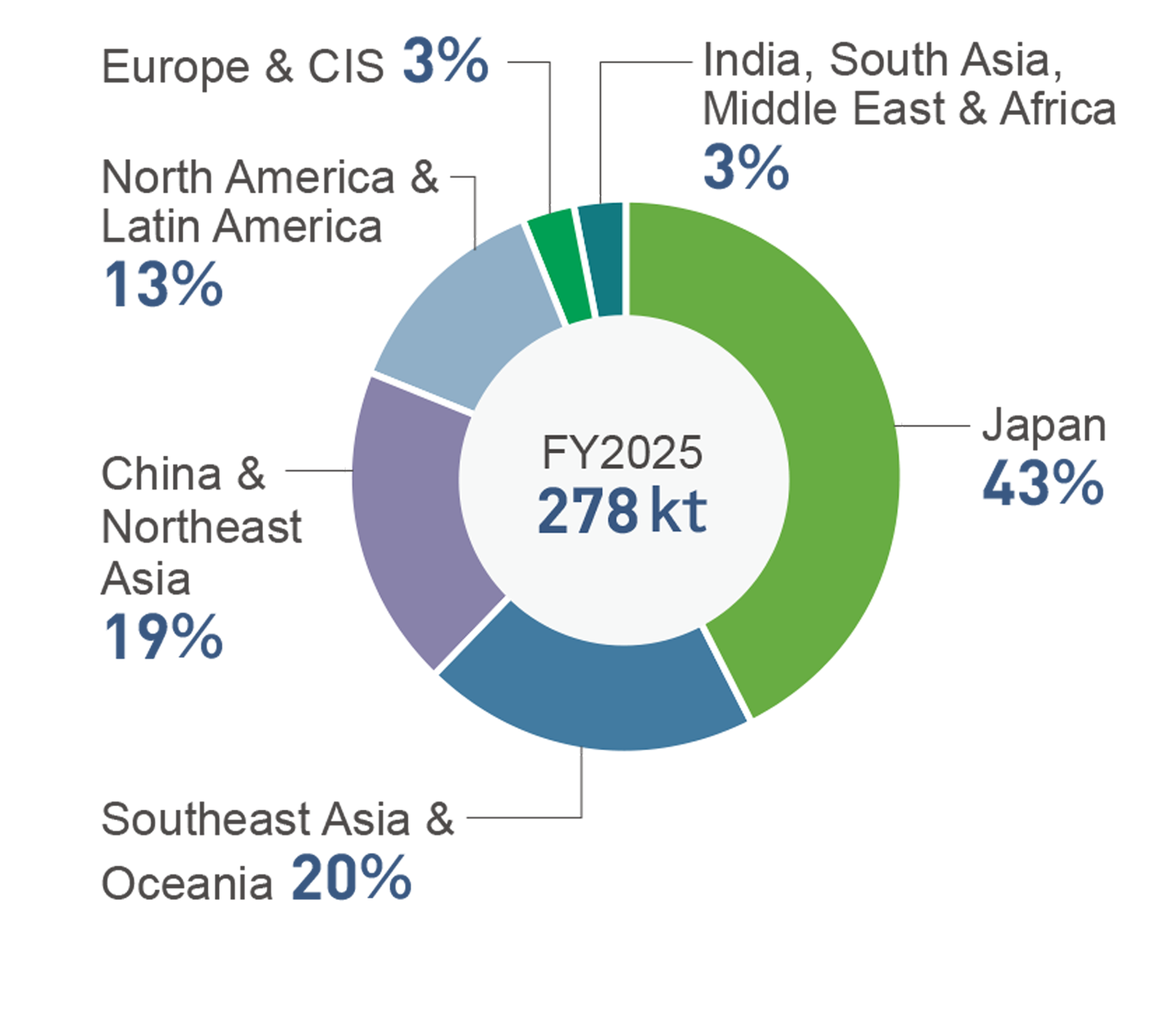

Breakdown of Total Wastes Including Revenue-generating Waste (by region)

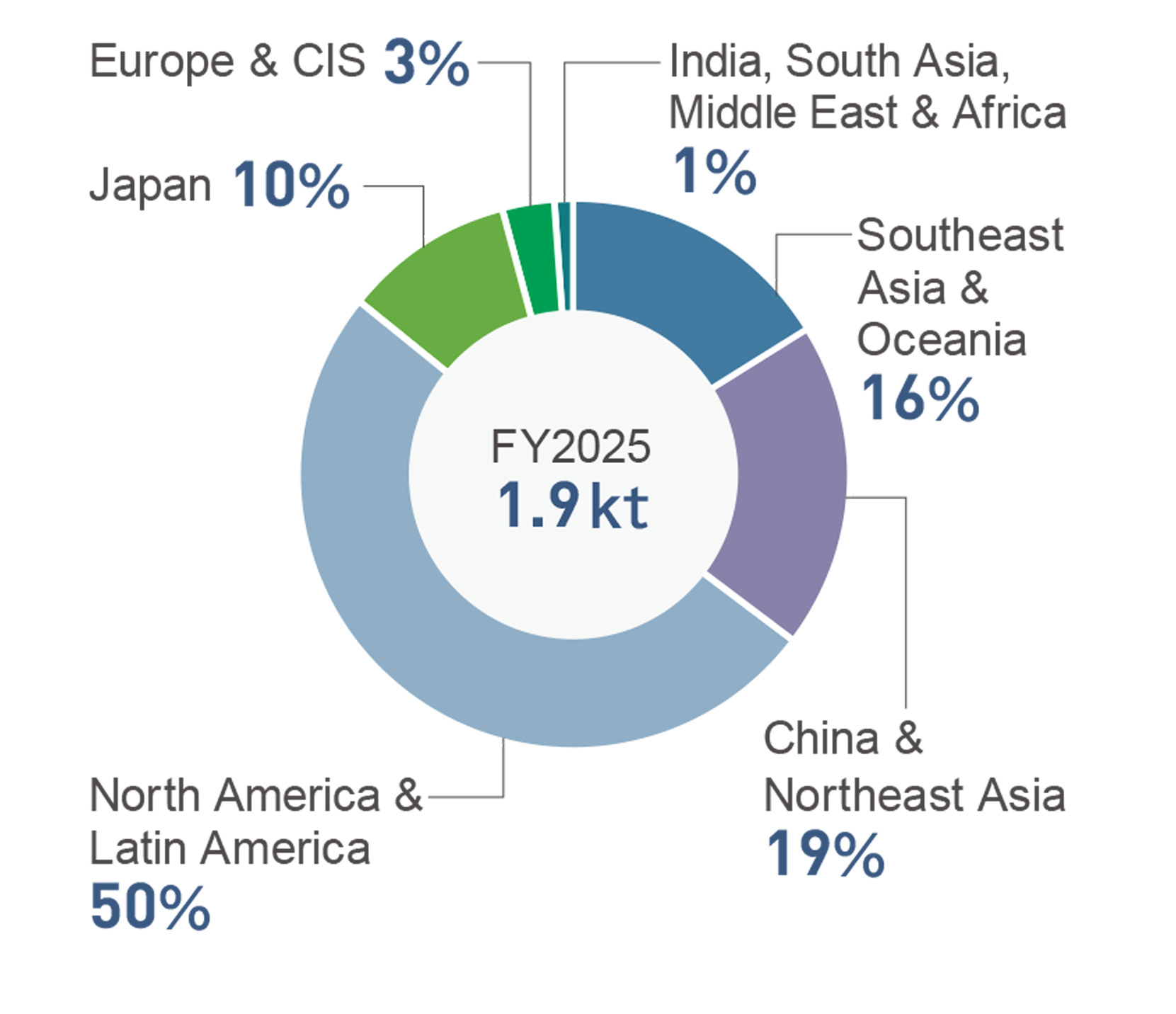

Breakdown of Landfill (by region)

Breakdown of Total Wastes Including Revenue-generating Waste for Fiscal 2025 (by category)

(kt)

Items | Total wastes | Recycled | Landfill |

|---|---|---|---|

Metal scrap | 122 | 120 | 0.03 |

Paper scrap | 30 | 29 | 0.1 |

Plastics | 33 | 32 | 0.6 |

Acids | 17 | 10 | 0.09 |

Sludge | 9 | 8 | 0.6 |

Wood | 25 | 24 | 0.03 |

Glass/ceramics | 3 | 3 | 0.06 |

Oil | 10 | 9 | 0.04 |

Alkalis | 18 | 16 | 0.03 |

Other*27 | 10 | 9 | 0.2 |

Total | 278 | 262 | 1.9 |

*27 Combustion residue, fiber scraps, animal residue, rubber scraps, debris, ash particles, items treated for disposal, slag, infectious waste, polychlorinated biphenyls (PCBs), waste asbestos.