Environmental Support for the Entire Factory

Business of Factory Support Service

Panasonic launched its Factory Support Service Business in April 2010, by making use of actual results in reducing CO2 emissions in production activities in the three years of fiscal 2008-2010. This service provides all-round support in energy-saving activities at factories, from visualization of energy use and energy efficiency diagnoses to execution of concrete energy efficiency measures, covering the aspects of technology, facility and equipment, human resources, and finance.

As part of this service, we have analyzed data which are managed by respective our customers, and understood the level of energy consumption efficiency with basic energies such as electricity and gas used in respective factories, physical data such as energy flow, pressure, temperature, and humidity that directly reflects the operation status of the facility and equipment. With the analysis results, we have supported the customers in swiftly formulating energy efficiency measures, making trial calculations, and improving accuracy of the verification.

At the beginning when the business started, we worked to clearly understand deterioration of equipment and necessity of its maintenance, through indicating variations of energy efficiency in long term in graphic displays with power equipment such as compressors, boilers, and freezers, and reduced their wasted energy consumption. Then, we accelerated energy efficiency activities, through paying attention to the production volume per basic unit calculated from the production volume and energy consumption, and utilizing the production volume per basic unit to "CO2 ITAKONA method" which timely extracts issues of production lines, and of facilities and equipment.

From fiscal 2020, we have further updated our activities; we have started the "Factory support service business" that formulates activities and plans for improvement in all of the areas related to the customer’s environmental sustainability management, including "energy-saving", "new energy and energy creation", "resource circulation" and "risk management."

In a contribution outside the company, in the 13 years from 2010 to 2023, we conducted diagnosis for approximately 789 cases, and provided energy-saving and factory support in the automotive-related, food, pharmaceutical, machinery, and electronic components industries in Japan. Moreover, we registered as a diagnostic service body dedicated to corporate energy efficiency diagnosis for 'Support for High-efficiency Installations for Facilities with Targets' led by the Ministry of the Environment, which provides information on the use of effective facilities and equipment, operational improvements, and the like, in order to reduce CO2 emission. We continue these energy efficiency activities.

By making full use of environmental technologies, know-hows, and experience which have been developed and established in Panasonic group, the service of the Total Environmental Package Solutions for Entire Factory, which provides a total solution that covers not only energy efficiency measures, but also environmental and energy technologies in wastewater treatment and drainage and water recycling, exhaust gas treatment, resources recycling, soil and groundwater purification, and photovoltaic power generation, has been developed. By enhancing the package service, we will further contribute to the comprehensive environmental solutions for Panasonic customers.

Examples of carbon neutral factories

Construction of RE100 Demonstration Facility at the Kusatsu Factory, Panasonic Corporation

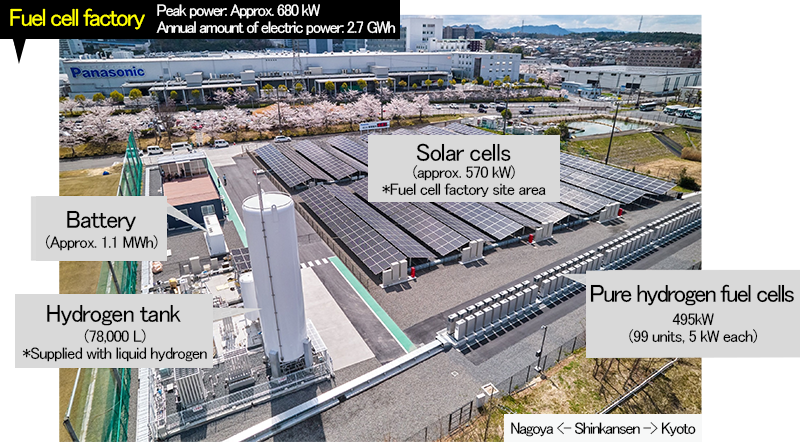

In FY 2021, our company contributed to the launch of the H2 KIBOU FIELD demonstration facility at the Kusatsu Factory (Panasonic Corporation). This facility combines pure hydrogen fuel cells (495 kW), solar cells (approximately 570 kW), and storage batteries (approximately 1.1 MWh) to provide a RE100 solution that uses 100% renewable energy for energy consumption in business activities.

The H2 KIBOU FIELD is a facility for achieving RE100 for the electric power used by the manufacturing department in the factory, as well as for developing and verifying technologies for optimal power supply and demand operation through coordination of three batteries.

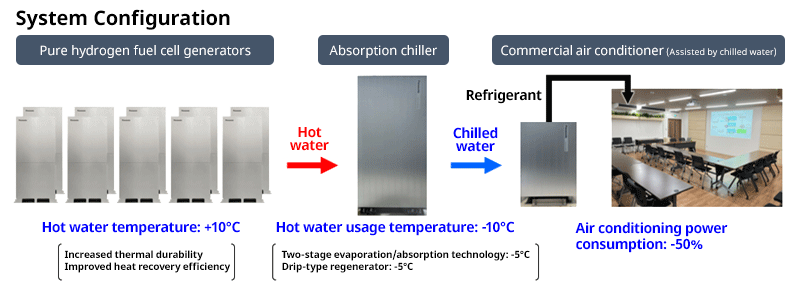

From the initial stage of consulting, we examined the configuration of solar cells and storage batteries, conducted simulations of power supply and demand in combination with fuel cells. We designed the facility to enable a wide range of demonstrations. In addition, we were able to successfully complete the world’s first demonstration facility by building on design and construction know-how through legal compliance with relevant ministries and agencies based on full-scale use of hydrogen power generation and coordination with hydrogen suppliers and electric power suppliers. In fiscal 2025, the above facilities were partially remodeled to design and construct a demonstration experiment to utilize heat produced during power generation using pure hydrogen fuel cell generators as a heat source for an absorption chiller (air conditioning equipment).

Utilizing this experience, we will continue to implement prompt and optimal proposals and construction both inside and outside the company.

*1 By using green hydrogen generated from renewable energy sources, including the use of environmental value certificates, it will be possible to comply with RE100. While hydrogen derived from renewable energy is not being used at the start of the demonstration, in the future we are aiming for RE100 using hydrogen derived from renewable energy.

*2 Demonstration of full-scale use of hydrogen as a fuel for in-house power generation to cover the factory’s operating power (as of March 31, 2022, according to research by Panasonic).

Use of heat from pure hydrogen fuel cell generators for air conditioning

Introduction of an EMS (Energy Management System) at Panasonic Energy Co., Ltd.’s Nishikinohama Factory

In fiscal 2025, PESENG introduced pure hydrogen fuel cell generators (30 kW) at Panasonic Energy Co., Ltd.’s Nishikinohama Factory, contributing to an increase in the ratio of renewable energy. In fiscal 2026, we will be installing one hydrogen holder (150 m3) as a fuel supply facility for the pure hydrogen fuel cell generators. We also plan to launch an EMS facility that combines pure hydrogen fuel cells with existing solar cells (approx. 2 MW) and storage batteries (approx. 2 MWh) in order to reduce peak energy consumption in business activities.

The newly introduced EMS is equipped with a “prediction function” not implemented in conventional systems. It automatically predicts energy consumption in business activities and the amount of power generated by solar cells, and performs peak shaving based on accurate thresholds in real time.

By introducing this EMS, we aim to reduce the amount of electricity used during the summer, when energy consumption is the highest, and to reduce contracted power consumption. We will analyze data throughout the year and aim to build a system that optimally controls the three types of batteries (fuel cells, solar cells, and storage batteries) according to the factory’s operating conditions and load fluctuations.

PESENG will contribute to reducing CO2 emissions throughout the Panasonic Group by deploying these technologies and initiatives at other sites.