CONTRIBUTION IMPACT

Panasonic is committed to contributing to the reduction of CO2 emissions for society and for its customers. For instance, by improving the performance and cost-efficiency of vehicle batteries to promote the adoption of environmentally responsible vehicles, replacing fossil fuel-based systems with electric heat pump water heaters, and implementing "Panasonic HX" solutions to ensure all energy consumed in business activities is sourced from 100% renewable energy, Panasonic is supporting electrification and the shift towards renewable energy, thereby contributing to the overall reduction of CO2 emissions in society.

Automotive Batteries

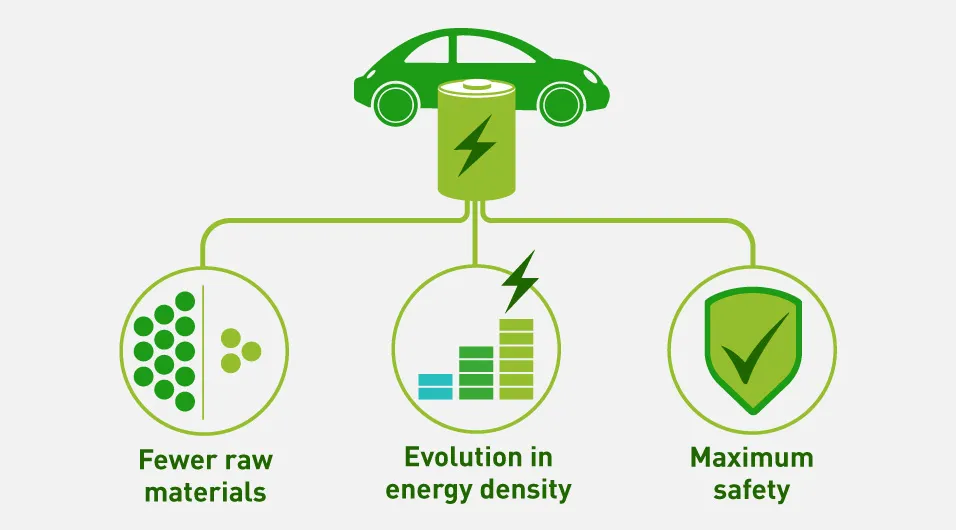

Panasonic's cylindrical Li-ion batteries for in-vehicle use deliver high energy density and safety.

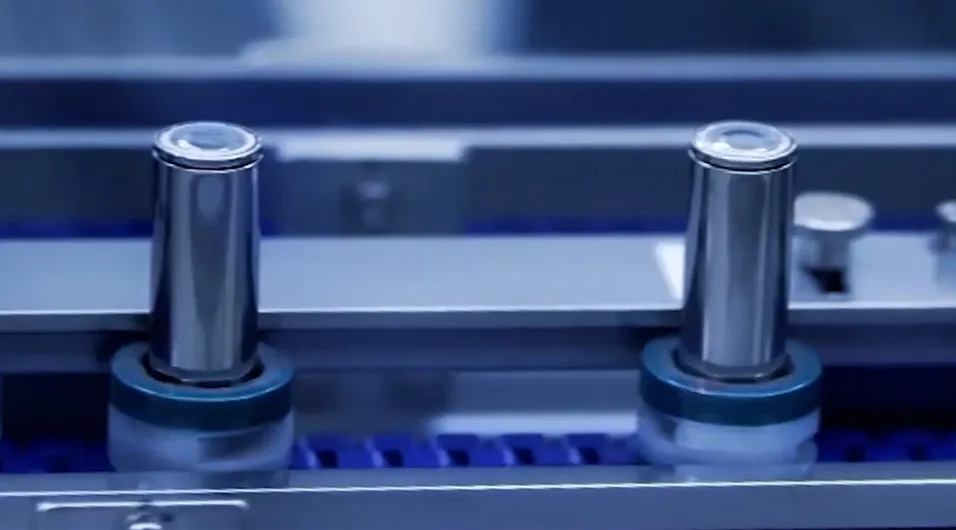

The Panasonic Group's automotive batteries were originally developed by adapting cylindrical Li-ion batteries, initially designed for notebook PCs, for use in vehicles.

Building on the inherent characteristics of cylindrical Li-ion batteries—durability and lightweight design—the Group has pursued continuous innovation to further enhance energy density and safety, while also optimizing cost-effectiveness. The cylindrical cell format also offers superior cooling performance, making it well-suited for fast charging that supports the broader adoption of electric vehicles (EVs).

Additionally, in the manufacturing of Li-ion batteries, efforts are underway to reduce the use of rare metals as part of resource conservation, while striving to improve the performance of automotive batteries and expand production capacity.

Features of cylindrical Li-ion batteries for in-vehicle use

Cylindrical Li-ion batteries for in-vehicle use are a focus of ongoing Panasonic technological innovation.

Strengthening battery production in line with EV market trends

The popularization of EVs is one of the most effective measures for realizing a decarbonized society. The Panasonic Group has been an industry pioneer in the North American market, producing high-performance, high-quality cylindrical Li-ion batteries at its Nevada facility, thereby contributing to the development of the EV market. In July 2025, the Group opened a second North American plant in Kansas, further strengthening its production system.

Panasonic Group automotive battery factories in North America continue to advance.

Kansas Factory (De Soto, Kansas, U.S.)

Expanding Our Automotive Battery Business to Increase Avoided CO2 Emissions

The Panasonic Group is working to maximize its contribution to avoided CO2 emissions through its in-vehicle business. In addition to reducing emissions by replacing fossil fuel–powered vehicles with EVs equipped with the Group's batteries, we are also reducing CO2 emissions across the entire product life cycle of automotive batteries, starting with emissions from our own factories.

At our North American sites, we are building a supply chain that reduces environmental impact by increasing the local procurement ratio of low-impact raw materials and minimizing the environmental burden of logistics. Furthermore, by utilizing recycled materials derived from used Li-ion batteries, we are contributing to lower CO2 emissions generated during resource mining. Through these initiatives in automotive batteries, we are contributing to the reduction of CO2 emissions across society.

Air-to-Water Heat Pumps

Air-to-Water (A2W) Heat Pumps: A Sustainable Solution for CO2 Emissions Reduction

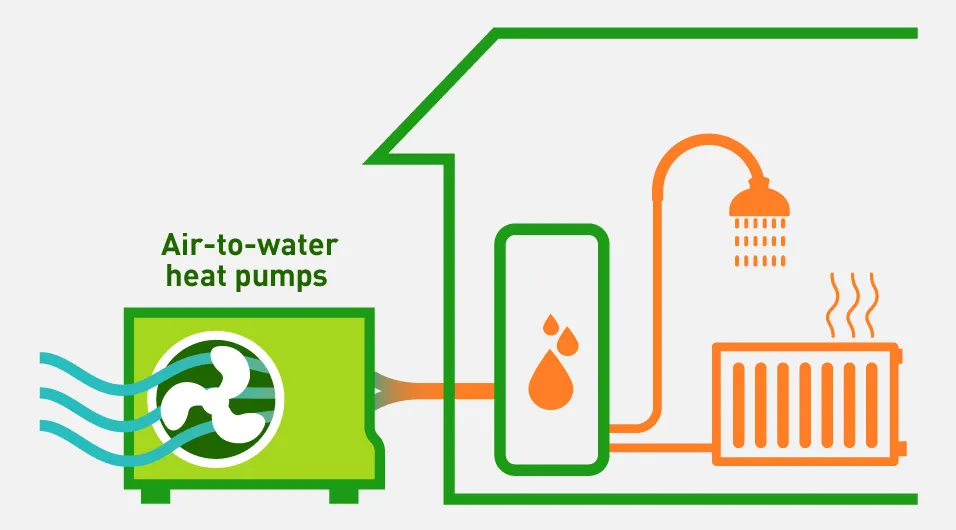

Air-to-Water is a heat pump water heating system that gathers heat from the atmosphere to produce hot water for circulation within the home. This innovative system offers a more sustainable alternative to traditional heating devices that burn fossil fuels. It is suitable for both new builds and existing homes, providing an eco-friendly option for replacing conventional heating equipment.

n Japan, production of Eco Cute4 household A2W heat pump water heaters began in March 2002. By March 2022, cumulative shipments reached 2 million units. This technology not only reduces CO2 emissions but also maintains heating efficiency even in cold climates. Moreover, products designed for the European market can serve as both heating and cooling devices, making them suitable for various regions.I

4 "Eco Cute" is branding used by Japanese electricity companies and water-heater manufacturers to designate natural refrigerant (CO2) heat pump water heaters for domestic use.

Contributing to reduction of CO2 emissions with hot water supply and heating that uses atmospheric heat

The Aquarea series heat pump hot water and heating system for the European market

Responding to Europe's Demand for A2W, and Helping Society Reach Carbon Neutrality

In Europe, efforts to combat climate change are progressing, and the demand for A2W is increasing year by year. By fiscal 2031, the market is expected to have undergone a dramatic expansion.

In various EU member states, subsidy programs have been introduced in line with the EU's decarbonization policies, accelerating the demand for A2W. Additionally, due to global conflicts, natural gas prices have surged in Europe, prompting a transition from conventional boiler heating to A2W.

The Panasonic Group aims to deliver high-efficiency A2W solutions, particularly in Europe, contributing to the reduction of CO2 emissions in the region.

Heat pump hot water and heating systems to meet the growing demand in Europe

Reinforcing A2W Operations in European Markets

To accelerate the growth of its A2W business in Europe, the Panasonic Group is establishing an integrated system for development, manufacturing, and sales within Europe, enhancing its competitiveness in the market.

Additionally, at our factory in the Czech Republic, we are expanding production facilities to increase A2W production capacity. Plans are to produce 550,000 units by FY2026, then 1 million units in the medium term, targeting avoided CO2 emissions of 11 million tons by FY2031.

Enhancing A2W production capacity within Europe

A2W Technology Reduces Environmental Impact While Enhancing Quality of Life

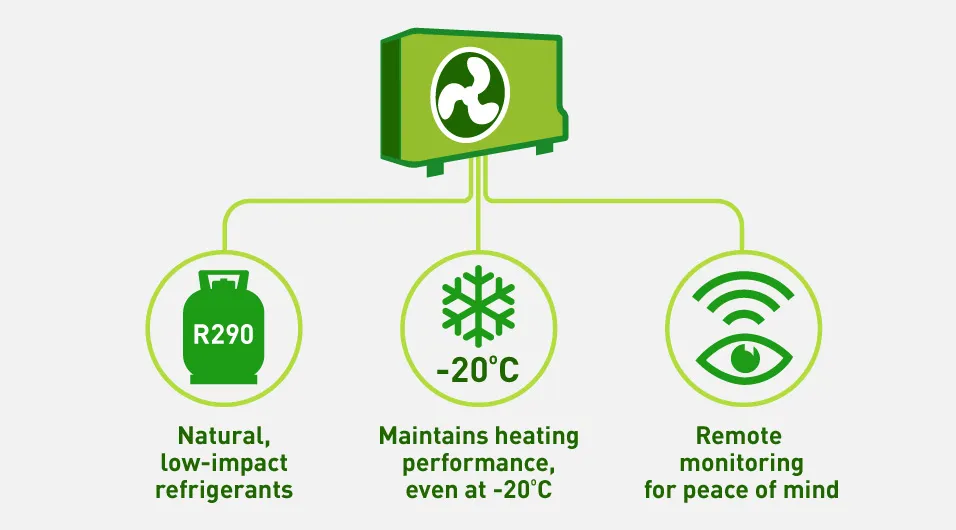

In A2W technology, the refrigerant plays a crucial role in transporting heat from the atmosphere. The Panasonic Group's A2W utilizes a refrigerant derived from substances naturally present in the environment, reducing environmental impact.

Furthermore, by leveraging the high heating capacity of this natural refrigerant, A2W maintains heating performance even in extremely cold regions, operating even with outdoor temperatures as low as -20ºC. A2W systems also offer features such as remote monitoring, enhancing users' quality of life.

Features of A2W

Pure Hydrogen Fuel Cells

Contributing to Carbon Neutrality Through the Widespread Adoption of Pure Hydrogen Fuel Cells

The widespread adoption of pure hydrogen fuel cells, which generate electricity using hydrogen, is a crucial aspect of the Panasonic Group's efforts to help achieve carbon neutrality.

Leveraging the technology of our Ene-Farm home fuel cell cogeneration system, these fuel cells offer excellent power generation efficiency with a compact form factor. They can be installed in various locations, such as rooftops, basements, and cramped spaces. Moreover, coordinated control of multiple units enables power generation output to be increased according to demand.

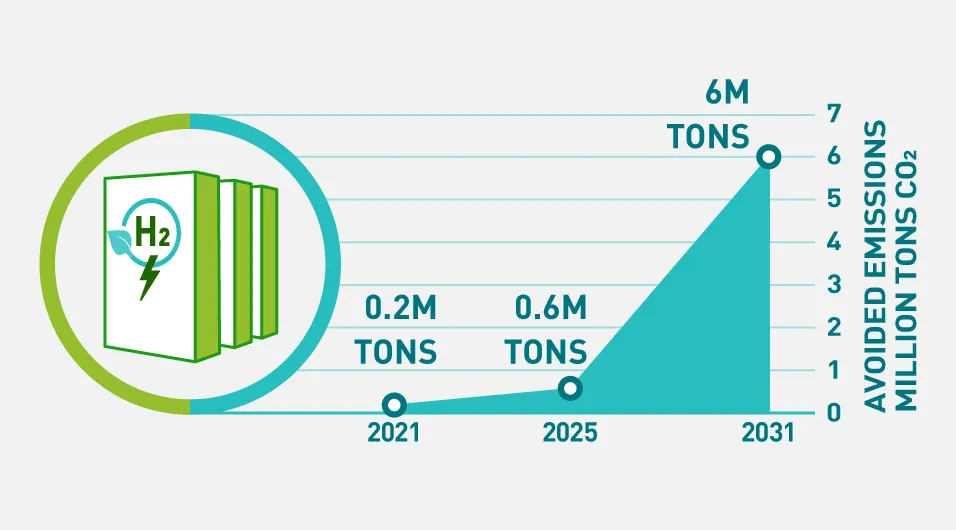

Through the widespread adoption of hydrogen fuel cells, we aim to increase our avoided emissions from 200,000 tons in fiscal 2021 to 600,000 tons in fiscal 2025, and again to 6 million tons by fiscal 2031.

Increase in avoided CO2 emissions due to popularization of pure hydrogen fuel cells

Panasonic HX

Accelerating the Demonstration of the Clean Energy Solution "Panasonic HX"

At its Kusatsu site in Shiga Prefecture, the Panasonic Group is conducting demonstration experiments of the clean energy Panasonic HX solution leveraging hydrogen fuel cells.

In addition, at Panasonic Manufacturing United Kingdom (PMUK), the Group has begun demonstrations of a power management system designed to cover 100% of the energy consumed in business operations with renewable energy, using on-site generation from pure hydrogen fuel cell generators and photovoltaic cells.

At PMUK, in addition to existing solar panels (372 kW), facilities have been newly installed including twenty-one 5 kW pure hydrogen fuel cells (total output: 105 kW) and a 1 MWh storage battery. This system is being used to test power supply and demand management that adapts to weather and local grid conditions in Cardiff, with the aim of supplying 100% renewable energy to the microwave oven factory.

Furthermore, by using pure hydrogen fuel cells, Panasonic is not only reducing installation space requirements and ensuring a stable power supply, but also improving energy efficiency by making use of the heat generated during hydrogen power production for heating and hot water.

Through these demonstrations at PMUK, Panasonic is working to develop energy solutions optimized to local conditions while also building partnerships with local companies and business customers in the hydrogen sector.

Due to the increase in CO2, Earth is the hottest it has been in 1,400 years, and climate change is accelerating.

CEO Kusumi shares the Panasonic Group's resolve regarding Panasonic GREEN IMPACT.

The Panasonic Group aims to create impact that reduces CO2 emissions by at least 300 million tons by 2050.

Carbon Neutrality

Circular Economy