OWN IMPACT

We will strive to achieve net zero CO2 emissions in our own value chain, along with the effect of the broader decarbonization of society1.

We are committed to achieving substantial carbon neutrality by FY2031 across all our group factories, including emissions during production of components and materials, as well as emissions during product usage, to reduce all CO2 emissions from our business activities to net zero levels.

1 The "decarbonization of society" refers to the improvement in the CO2 emission coefficient of electricity as various power supply operators progress in their decarbonization efforts.

Reducing CO2 Emissions in Factories

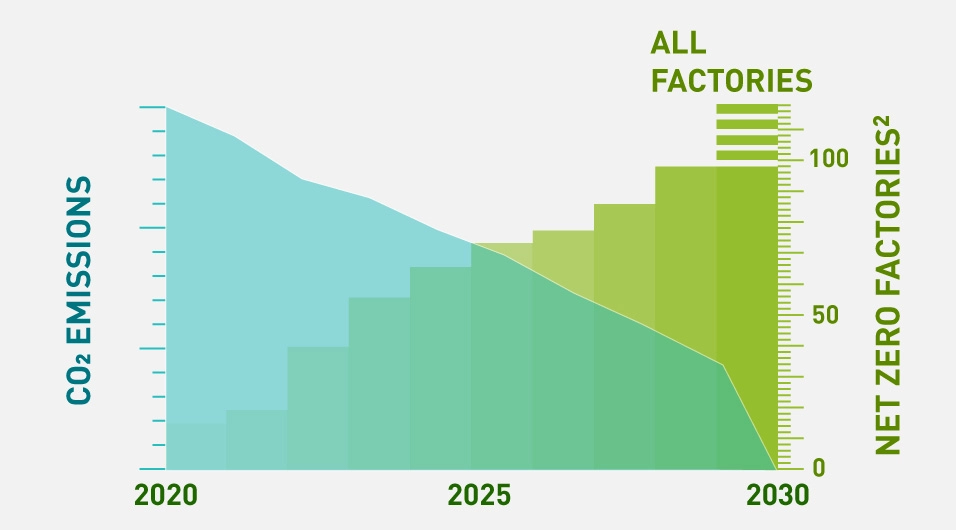

By 2030, We Aim to Attain Net Zero CO2 Emissions at All Our Factories

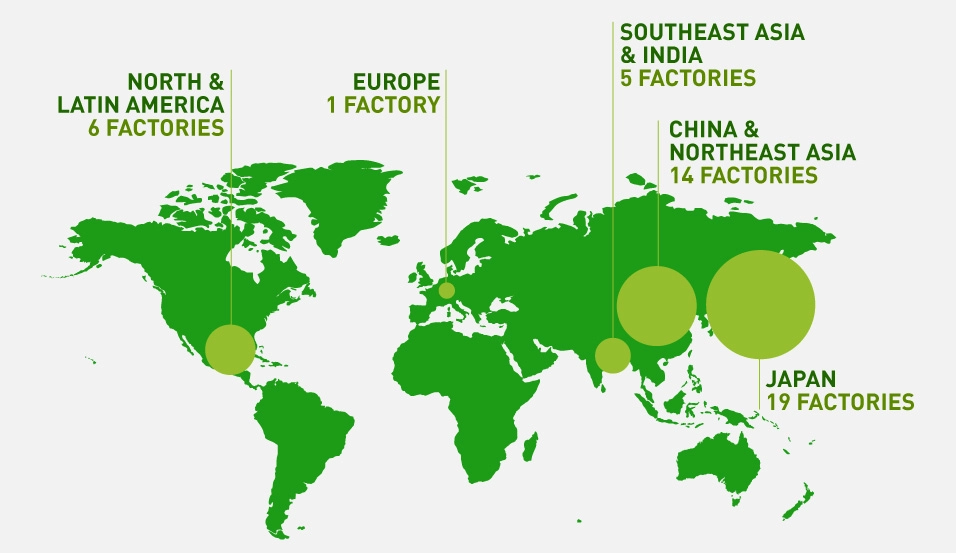

As of fiscal 2025, the number of factories of about 250 Panasonic Group factories that have already reached this milestone had reached 45, achieving the fiscal 2025 target of 37 factories. We are continuing to increase the number of our net zero factories2 with the aim of ensuring that all our factories have gained this status by 2030.

2 Factories that achieved net zero CO2 emissions through the combined promotion of energy saving activities, the introduction of renewable energy, and the utilization of energy certificates and carbon credits.

3 Excluding the 12 plants of Panasonic Automotive Systems Co., Ltd. that achieved their targets in FY2024 and which, as of December 2024, ceased to be consolidated subsidiaries.

Aiming for net zero CO2 emissions at all factories by 2030

The Key to Achieving Net Zero Factories2 Lies in Saving Energy and in the Utilization and Procurement of Renewable Energy.

Our efforts toward achieving net zero factories2 include adopting energy-saving measures such as transitioning to LED lighting and implementing energy management systems utilizing AI.

The introduction of solar power systems, energy storage systems, hydrogen fuel cells, and the combination of utilizing renewable energy on-site and procuring 100% renewable energy externally, also help us reduce factory CO2 emissions to net zero.

2 Factories that achieved net-zero CO2 emissions through the combined implementation of energy conservation measures, the introduction of renewable energy, and the utilization of electricity certificates and CO2 credits.

Initiatives targeting net zero factory2 operations

Panasonic Electronic Devices Jiangmen (PEDJM) Solar Power System

Initiatives at Panasonic Eco Technology Center and Beyond

In January 2019, Panasonic Eco Technology Center (PETEC), our home appliance recycling facility, became our first net zero factory2.

Through adopting solar power systems, sourcing electricity from renewable energy, and offsetting fossil fuel-derived CO2 emissions under the Japan Credit Scheme, PETEC successfully attained net zero CO2 emissions.

2 Factories that achieved net-zero CO2 emissions through the combined implementation of energy conservation measures, the introduction of renewable energy, and the utilization of electricity certificates and CO2 credits.

At our Panasonic Energy Wuxi (PECW) factory in China, CO2 emissions were reduced to net zero in fiscal 2022. This was facilitated by introducing energy-saving measures and solar power systems, and by procuring renewable energy. In February 2022, PECW launched a demonstration experiment using pure hydrogen fuel cell generators to supply the facility with both electricity and heat.

Panasonic Energy Wuxi (PECW)

Panasonic Energy Wuxi (PECW) Solar Power System

Energy-Saving Home Appliances

By Refining Technologies such as ECONAVI Intelligent Sensors, Panasonic is Committed to Making Home Appliances Thoroughly Energy-Saving.

Through our OWN IMPACT efforts, Panasonic aims to reduce not only the CO2 emissions generated when we manufacture products, but also those generated when our products are used. Air conditioners and refrigerators serve as prime examples of Panasonic Group's commitment to energy-saving appliances. By refining unique technologies like ECONAVI Intelligent Sensors, which enable home appliances to automatically identify and reduce electricity wastage, Panasonic will further enhance energy-saving in home appliances.

ECONAVI functionality enables home appliances to save power automatically.

Due to the increase in CO2, Earth is the hottest it has been in 1,400 years, and climate change is accelerating.

CEO Kusumi shares the Panasonic Group's resolve regarding Panasonic GREEN IMPACT.

The Panasonic Group aims to create impact that reduces CO2 emissions by at least 300 million tons by 2050.

Carbon Neutrality

Circular Economy