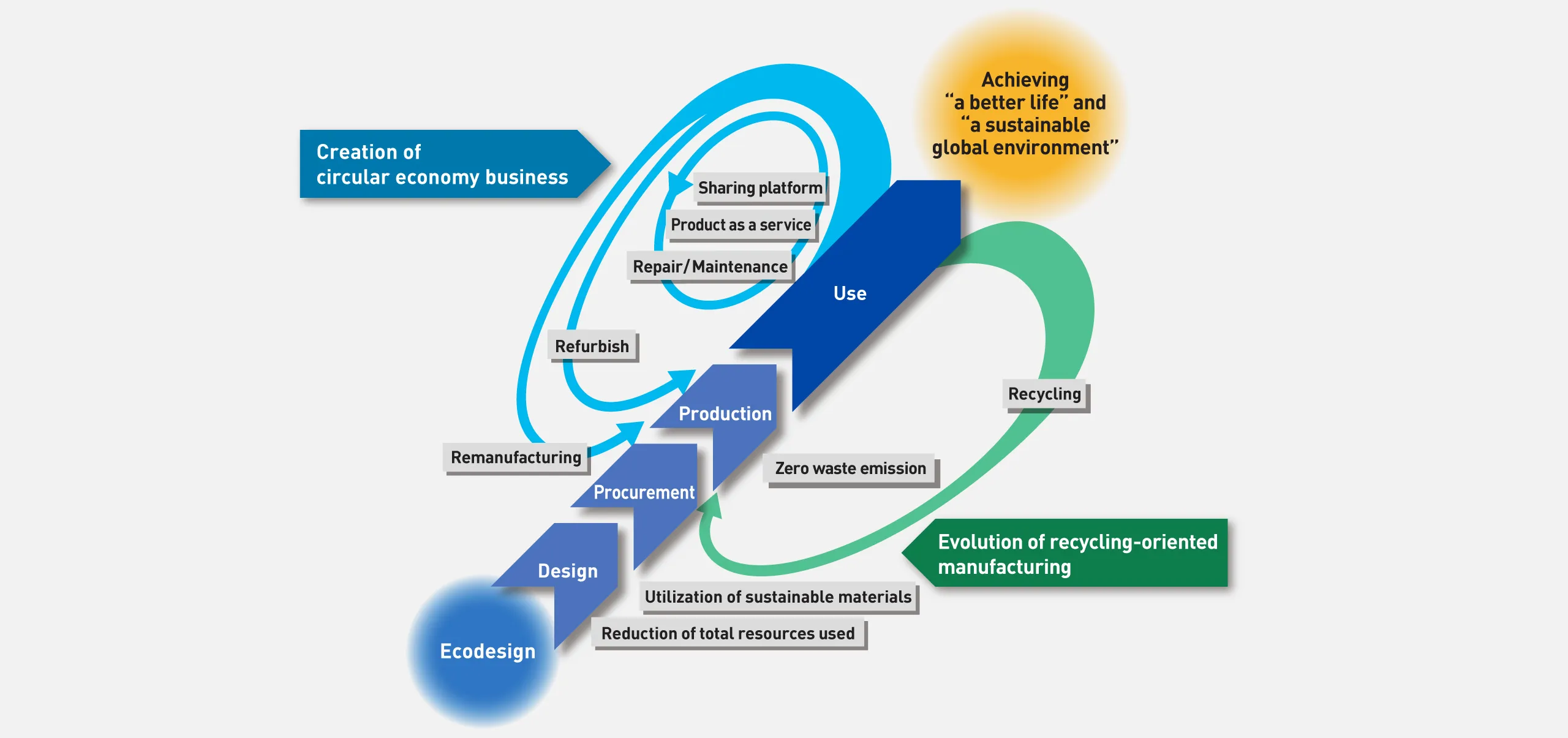

Along with changes in customer lifestyles, there is now a growing global trend for customers to use only specific functions of a product, rather than using or owning the whole product. Particularly in Europe, building a circular economy for sustainable economic growth has become a major economic strategy, in a move away from continuous resource consumption. Amid this development, the Panasonic Group is introducing the idea of circular economy and moving forward in efforts to promote effective utilization of resources and maximization of customer value.

Promotion of a Circular Economy

Striving for the Evolution of Recycling-Oriented Manufacturing and the Creation of Circular-Economy Business

Recognizing that more efficient utilization of resources contributes to decarbonization, and is necessary for reducing the consumption of Earth's limited natural resources, Panasonic is striving towards a circular economy in order to contribute to the realization of a sustainable society.

Advancing with Recycling-Oriented Manufacturing

We will continue our existing activities aimed at reducing the total amount of resources used, utilizing sustainable resources, striving towards zero waste emissions from production, and promoting the recycling of our products. Furthermore, we will use innovative materials and the latest digital technologies to enhance recycling-oriented manufacturing.

Creation of Circular Economy Business

In order to help consumers realize the new value of using only product functionalities, instead of using or owning the whole product, we will strive to create businesses such as sharing services, where multiple users use the same individual product, Product as a Service, where service needs are fulfilled based on required functions, and repair and maintenance, refurbishing and remanufacturing, where functions, values, and the lifecycle of a product are utilized in the most efficient manner by recycling or reusing the product itself or the components used in the products.

Cooperating with our customers and partner companies, we are creating a new approach to recycling-oriented management, information sharing, and product usage.

Cellulose Fiber Resin

Transforming Discarded Plant Resources into New Materials

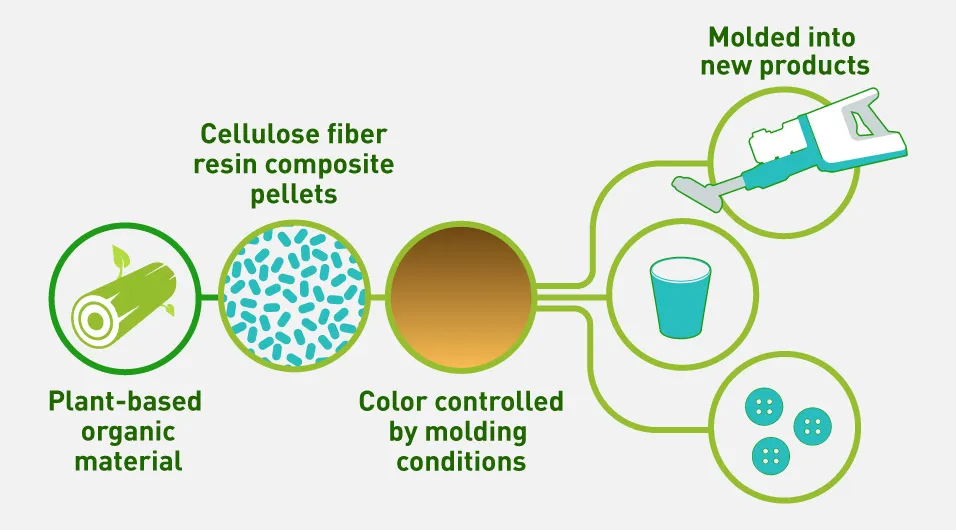

Aiming to reduce our usage of petroleum-derived resins, the Panasonic Group has developed a high-performance plant-based material in the form of a cellulose fiber resin we call kinari.

By extracting plant fibers (cellulose) from forestry thinnings and other hitherto-discarded plant resources and mixing them with resin at high density using our enhanced proprietary technology, we can leverage the properties of the raw materials to create a material with a wood-like texture and scent that can be processed into complex shapes. Through collaborative efforts with companies, local government bodies and other parties, this cellulose fiber resin is now being utilized in environmentally responsible products like reusable cups and buttons.

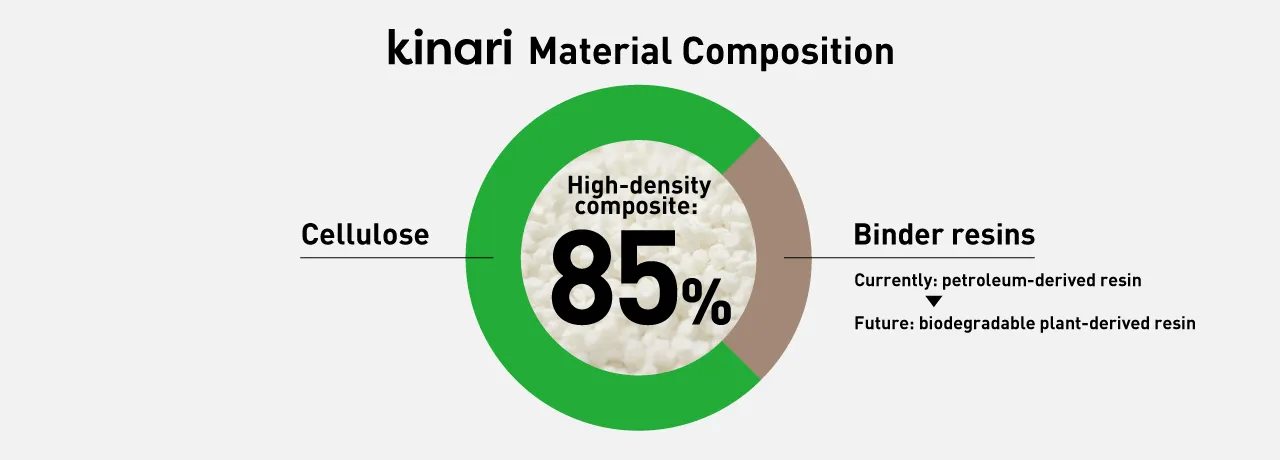

Achieving both biomass level (environmental responsibility) and strength (functionality). (Cellulose composition is based on weight ratio/experimental ratio. Commercialized up to 55%, molding tested up to 70% as of 2021)

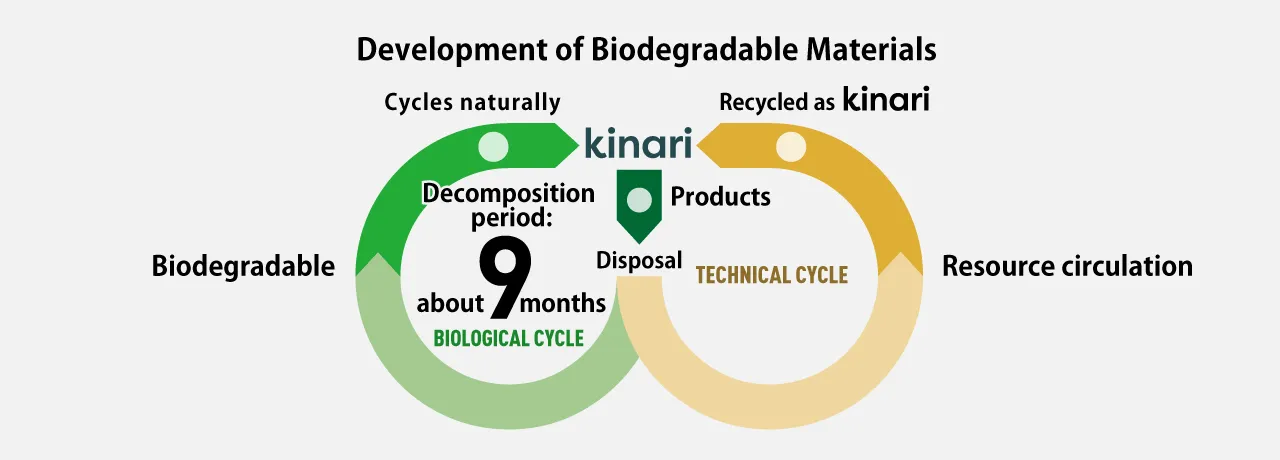

Development targeting 100% biodegradability, including binder resins

High-density cellulose fiber molding material

Reusable cups made using high-density cellulose fiber molding material

Buttons and spindle stoppers made using high-density cellulose fiber molding material

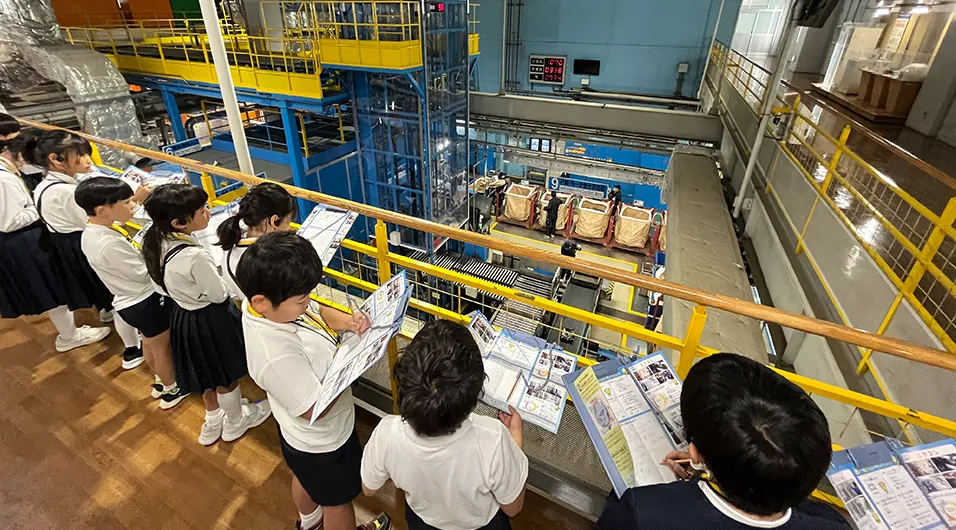

PETEC

Panasonic Eco Technology Center—a Multipronged Approach to Circular Economy

Established in 2001, Panasonic Eco Technology Center (PETEC) is the Panasonic Group's own recycling hub for used home appliances. Besides pursuing technology development, it recovers resources from used home appliances, working efficiently and achieving high levels of purity, and engaging in activities aimed at transforming these resources into materials for the production of innovative products. In addition to contributing to the wider utilization of recycled resources and the development of recycling technology, PETEC conducts factory tours to raise awareness of the importance of resource recycling, sharing its insights with society.

The MULTISHAPE Series Modular Personal Care System

Contributing to Environmental Impact Reduction Through Thoughtful Design

Targeted at the European and North American markets, Panasonic's MULTISHAPE Series Modular Personal Care System is thoughtfully designed to use minimal resources.

It's a single device for which five detachable heads are available, covering a range of grooming functions including tooth-brushing, facial hair clipping and trimming. A customer doesn't have to purchase all five heads: instead, he or she can select only the ones needed. Also, because all five heads are powered by a single main unit, the product weighs about 60% less than conventional models.

The MULTISHAPE Series modular personal care system won the iF Design Award 2023 Gold Award.

Panasonic Factory Refresh (Panasonic Certified Refurbished Products)

Refurbishing Panasonic Appliances

At the official Panasonic online store in Japan, we're implementing an important part of our circular approach to manufacturing. We refurbish products returned by customers to a reusable state and then resell them. Only those items that meet high quality standards of Panasonic factories are offered to our customers.

Refurbishment Factory in Utsunomiya, Tochigi Prefecture, Japan

Note: Refurbishment is also undertaken at several other locations in Japan

Washing machine refurbishment facility

Television refurbishment facility

Information related to recycling-oriented manufacturing

Achievements in the Creation of Circular Economy Businesses

Panasonic Expanded to 15 Circular Economy Businesses in Fiscal 2025

The Panasonic Group continues to transform existing businesses into circular economy businesses, expanding by 2 from 13 in fiscal 2024 to 15 in fiscal 2025, achieving our goal. Going forward, we will continue to create more such businesses.

Our Refurbishment Partnership with Lawson

Under a partnership with Lawson, the Panasonic Group is refurbishing stores in Chongqing, Shanghai, and other areas, rolling out a re-use service, and striving to reduce building waste. The Lawson store opened in Nanjing in July 2020 generated significantly less building waste thanks to prefabricated construction and material recycling. The same kind of stores have also been built in Shenyang and Tianjin.

Prefabricated Lawson store

Panasonic "noiful" Home Appliance Subscription Service Delivers a Burden-free Lifestyle.

Our "noiful" home appliance subscription service for renters offers a special kind of appliance package that leverages the unique capabilities of the Panasonic Group. The latest Panasonic devices are pre-installed in the rental home, and users are provided guidance in appliance usage. Prompt repair and replacement services are provided, along with appliance cleaning when renters move in or out.

Project Aimed at Developing a Utilization Ecosystem Using Factory Offcuts as Principal Materials

To reduce the waste of resources generated in the factory manufacturing process, the Panasonic Group is working to build up expertise and systems to use factory offcuts as-is as much as possible, and upcycle them into attractive products.

This offcut utilization ecosystem development project adopts a three-pronged approach, focusing on data utilization, a secondary-use ecosystem, and collaboration with creators to transform offcuts from synthetic marble used for kitchen counters and other items into new products. Using this initiative as a model case, we aim to create a new resource life cycle.

Upcycling synthetic marble offcuts to make a table.

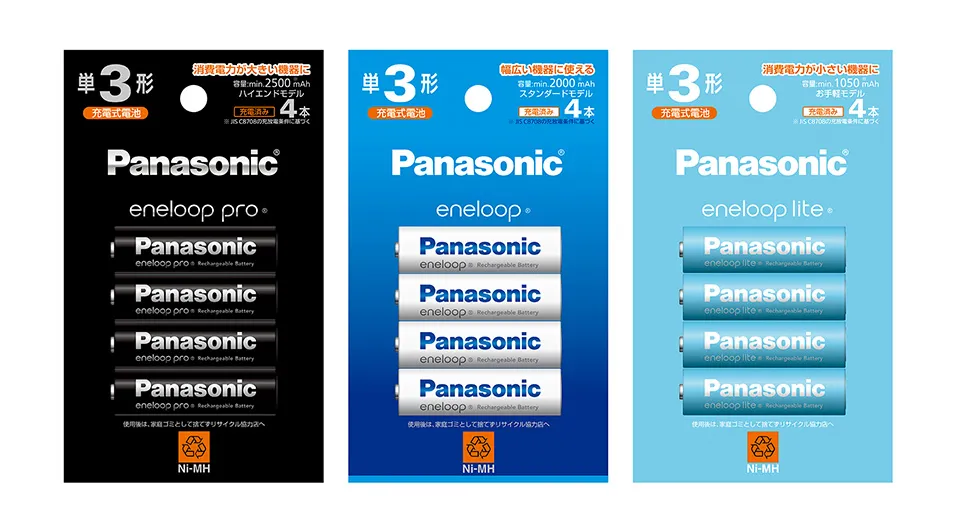

Adoption of Paper-Based Packaging for Dry Cell Batteries

In response to the growing interest in ethical consumption or in other words, environmentally responsible consumer behavior, the Panasonic Group is working on adopting paper-based packaging that reduces environmental impact while still being user-friendly. Our first step in this direction was the introduction of environmentally responsible packaging for some models of our EVOLTA NEO dry cell batteries in October 2021. Since April 2023, we have been rolling out environmentally responsible packaging for a broader range of models.

Our adoption of environmentally responsible packaging for our eneloop rechargeable nickel hydride batteries has reduced the amount of packaging materials used by between 38 and 70%1 compared with conventional blister packaging. By rolling out environmentally responsible packaging across the lineup, we will achieve an annual reduction of approximately 5.7 tons of plastic and 21.5 tons of paper, adding up to a total of approximately 27 tons of packaging materials.

1 For the eneloop pro models BK-3HCD/4C and BK-4HCD/4C and the eneloop models BK-3MCC/4C and BK-4MCC/4C, compared with the models using conventional blister packaging (eneloop pro BK-3HCD/4H and BK-4HCD/4H, and eneloop BK-3MCD/4H and BK-4MCD/4H)

Paper-based packaging for rechargeable batteries

Due to the increase in CO2, Earth is the hottest it has been in 1,400 years, and climate change is accelerating.

CEO Kusumi shares the Panasonic Group's resolve regarding Panasonic GREEN IMPACT.

The Panasonic Group aims to create impact that reduces CO2 emissions by at least 300 million tons by 2050.

Carbon Neutrality

Circular Economy